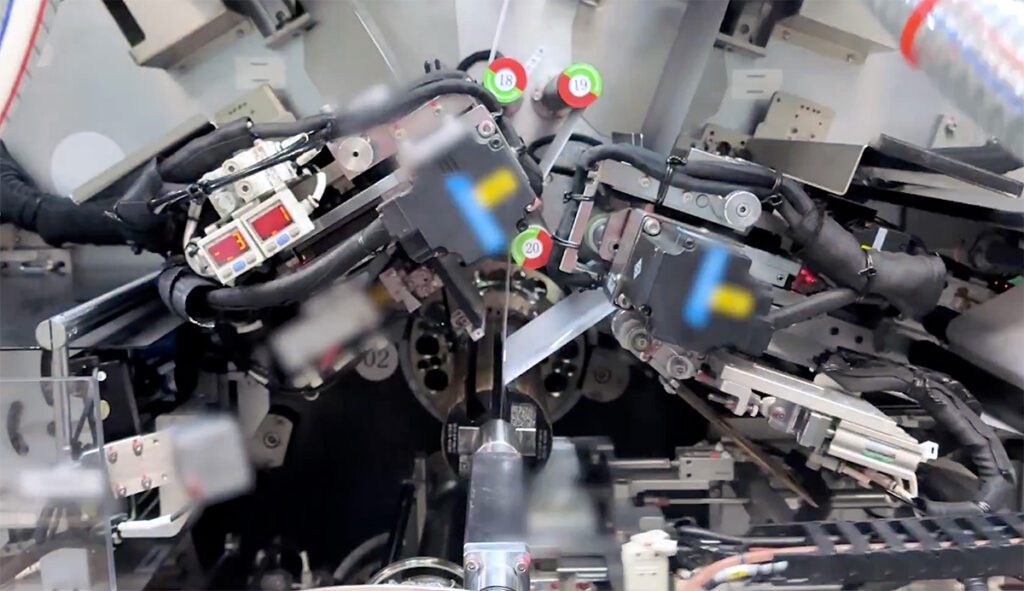

German material and manufacturing specialist Heraeus Additive Manufacturing has developed a new way to manufacture highly conductive copper components on a standard 3D printer.

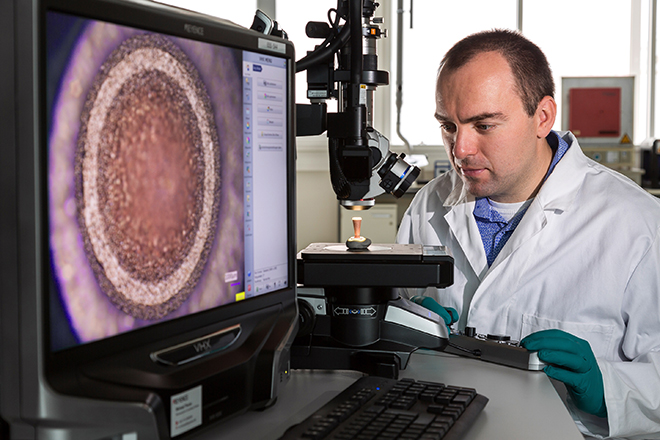

The new process produces components with 99.8 percent density of solid copper and conductivity of about 95 percent on the International Annealed Copper Standard scale – according to Heraeus, around 85 percent IACS is customary in the market.

Copper has high conductivity and ductility, but reflects the laser wavelength that is used in standard machines almost like a mirror. Also, the high thermal conductivity of copper causes quick dissipation of the coupled energy. This results in a narrow process window, and makes conventional 3D printing of pure copper impossible.

“With this boost in quality, additive manufacturing of highly conductive copper components is now possible, worthwhile and cost-efficient in many industrial sectors,” says Tobias Caspari, Head of Heraeus Additive Manufacturing. He adds that the new process can reduce the time required for spare parts procurement from several months to a few days.

Applications include components of electric drives, inductive heating and thermal management.

In conventional manufacturing processes, manufacturing tolerances are often too high to achieve reproducibility in particularly sensitive manufacturing processes, Caspari says. “We’ve solved this problem as well. We’re now working on further increasing the conductibility of micro-alloyed copper and applying our findings to other standard machines.”

Source: Heraeus