FREYR Battery is replacing its plan to build two gigafactories with a plan to build a single gigafactory which increases capacity by 150%. The estimated construction cost will be $1.7 billion. “FREYR is increasing the nameplate capacity of Giga Arctic to 29 GWh in response to improving battery supply-demand dynamics, ongoing commercial success, significant progress in developing supply chain channels for key raw materials and equipment, continued technical and product improvements and project financing visibility,” the company says.

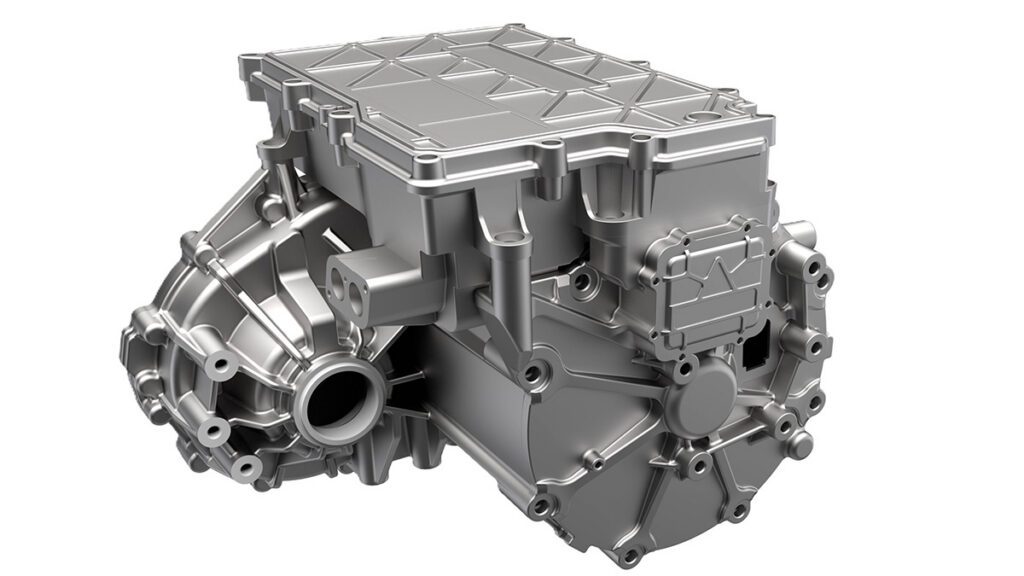

Giga Arctic will be built in Mo I Rana, Norway, and will consist of eight production lines, a battery testing center, administrative facilities and infrastructure. “Giga Arctic is expected to be one of the largest and most efficient battery facilities in Europe, with 50% lower anticipated capital spending per GWh of nameplate capacity and more than 200% higher production per employee than conventional lithium-ion battery plants in production today,” according to the company.

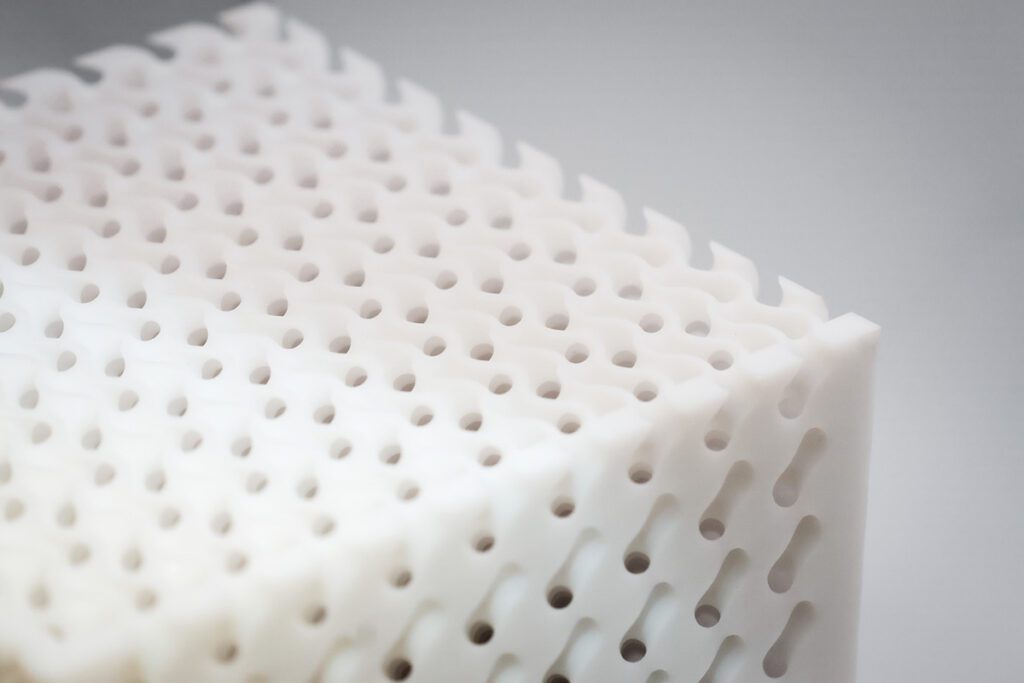

“These expected efficiencies are aided by FREYR’s recently announced long-term power purchase agreement with Statkraft,” says the company. “Giga Arctic is expected to benefit from 100% renewable energy at prices that FREYR estimates to be substantially below those of other battery-producing regions, while using less energy in production through the 24M Technologies SemiSolid cell manufacturing process and platform.”

The company plans to contract about 50% of Giga Arctic’s capacity to long-term offtake partners, has reached an offtake agreement with a European energy technology customer for 25 GWh of cells from 2024 to 2028, and has entered conditional offtake agreements for another 100 GWh.

FREYR is also assessing the possibilities of module and pack manufacturing and recycling for the facility as well as a proposed joint venture with battery materials company Aleees on a LFP cathode materials manufacturing plant in the Nordic region.

Source: FREYR Battery