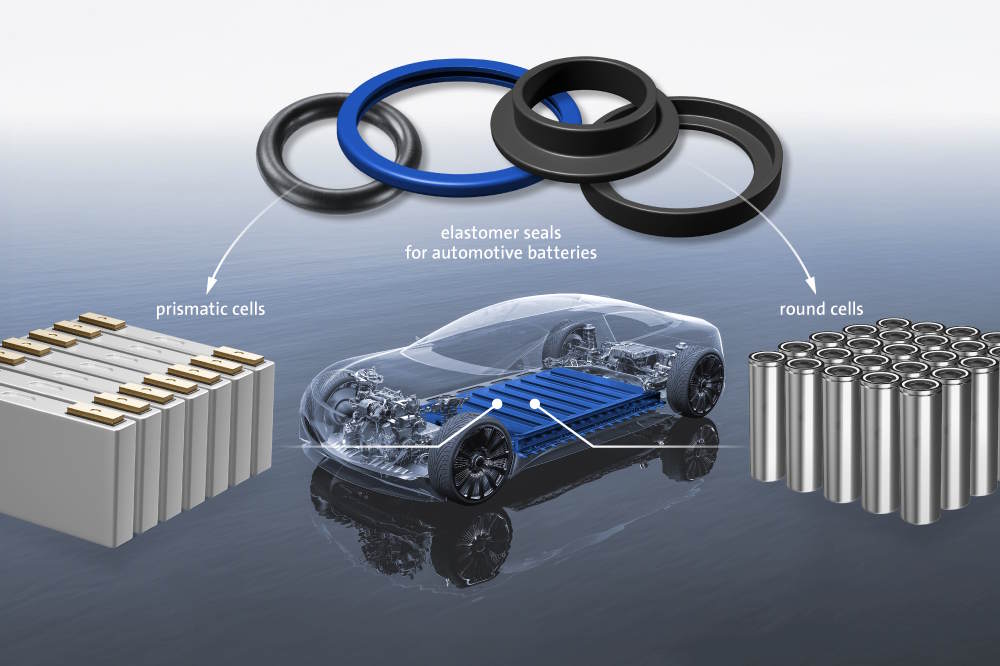

Germany-based Freudenberg Sealing Technologies has developed a new, highly compatible elastomer material for automotive applications as an alternative to PFAS-containing thermoplastic and FKM seals.

The new material series is processed by injection molding, delivers high-performance sealing, ensures battery life and meets international environmental regulations.

“Our O-rings made from the new elastomer prevent electrolytes from leaking out of the battery cell or impurities from entering the cell,” said David Kuhne, Application Engineer at Freudenberg Sealing Technologies. “You shouldn’t think of a battery cell as a rigid construct—it breathes. When the temperature in the battery cell rises from ambient levels to—as a rule—ranges of up to 60° C, the cell expands and then contracts in the same way as it cools. Elastomers show significant advantages over thermoplastics during this continuous stress.”

“Premature capacity loss, which has been observed in cells sealed with conventional elastomers, can result from minimal but still present impurities in the sealing material. The infiltration of moisture into the cell has a similar effect, as it can cause the decomposition of electrolyte components. These aspects were considered when the new material was developed,” said Dr. Stefan Schneider, Head of Material Development at the O-Rings lead center.

Source: Freudenberg Sealing Technologies