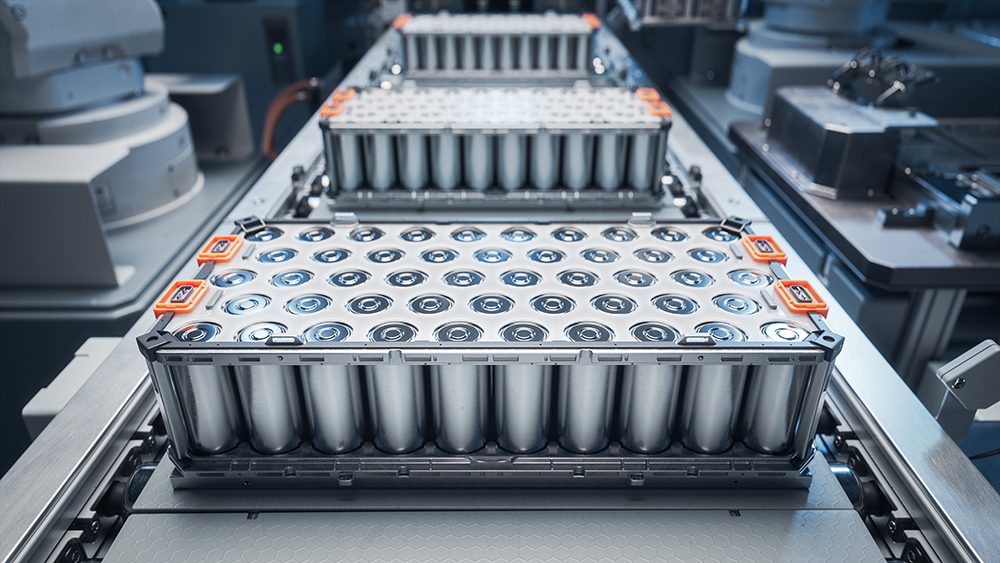

German research institute Fraunhofer FFB has started a three-year project, TRAICELL, to develop battery data tracking and optimize cell production.

The project, funded by the German Federal Ministry of Education and Research, aims to create three near-series prototypes and three scaling stages of battery production.

The system will enable the tracking of production and quality data down to individual electrode layers. The goal is to increase efficiency and quality by simultaneously optimizing the mixing and coating processes. At the end of the project, machine learning models will make it possible to predict cell quality in early production phases to minimize waste and improve material yield.

Along with the Fraunhofer Research Institution for Battery Cell Production FFB, TRAICELL also involves the German electrode and cell manufacturer UniverCell, BST as a full-service provider of quality assurance systems, and AI developer Merantix Momentum. The consortium will develop and test the systems developed on various scales from pilot to near-series production.

“Innovative solutions—including those from digitalized battery cell production—must be transferred from research to industry more quickly,” said PEM Director Professor Achim Kampker. “In future, it will be important to be able to make reliable quality predictions during the forming process to reduce production times and detect rejects at an early stage.”

Source: Fraunhofer