While researchers around the world seek to develop better battery chemistries, the EV-Lite project has been working on a more mundane goal, but one that could also lead to more cost-effective batteries: reducing the weight and cost of the non-cell components of a battery pack.

The two-year project, which was undertaken by a consortium of companies, universities and research institutions, and was co-funded by the UK’s innovation agency, the Technology Strategy Board, is drawing to a close, and has succeeded in surpassing its targets. The researchers achieved a 41% reduction in weight and a 63% reduction in cost, which translates to a savings of 45 kg at the battery pack level.

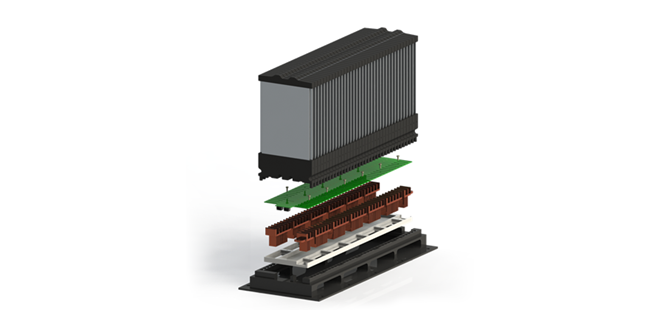

The new battery pack uses no wire or screws, and is designed for low-cost, automated assembly. Compared to a benchmarked battery, the EV-Lite design has a parts count of 196 versus 807 for a 4 KwH module.

The lead partner, the Manufacturing Technology Centre, has manufactured two prototype battery packs, and the Centre of Excellence for Low Carbon and Fuel Cell technologies (Cenex) managed the battery test and validation package.

The prototype pack and the mobile robotic cell used for automated assembly will be presented to the public at the Cenex-LCV Low Carbon Vehicle event in September.

Source: Cenex