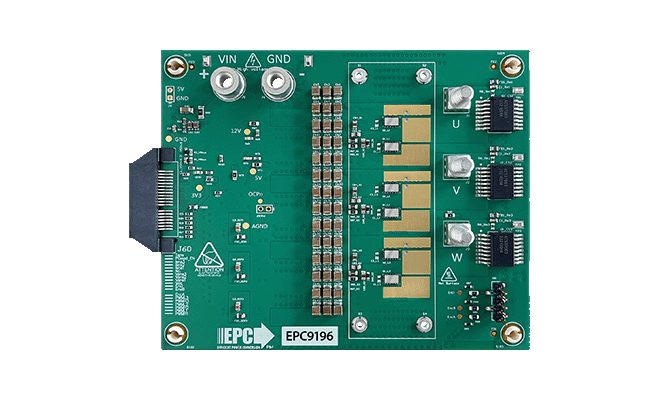

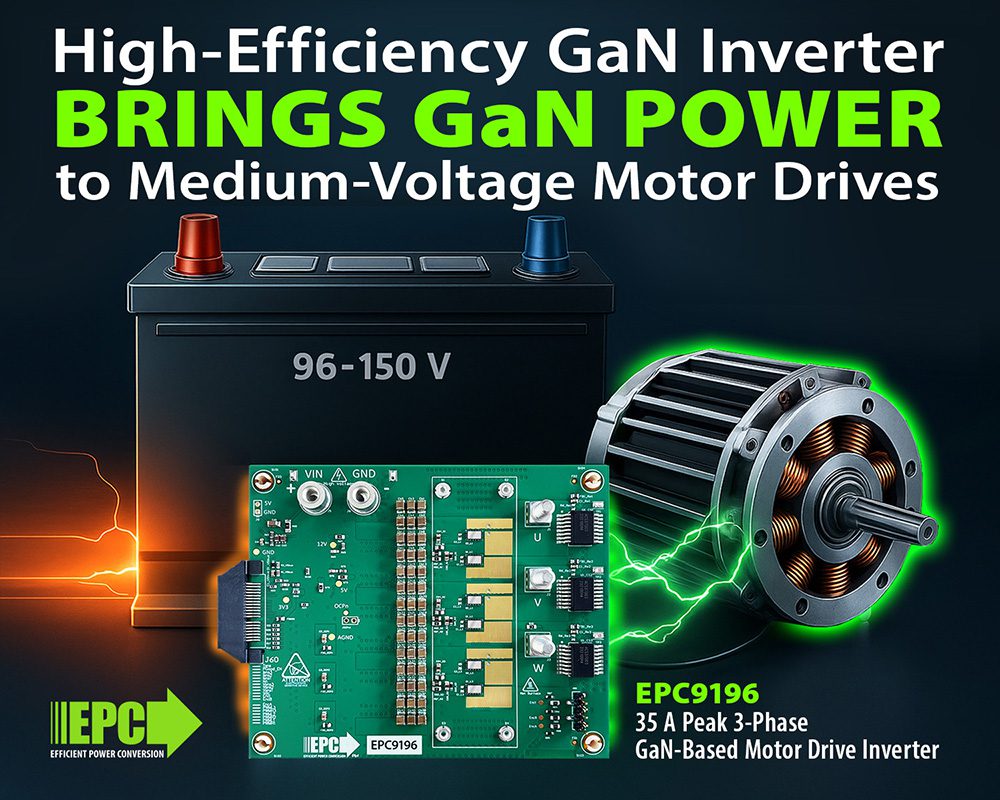

US-based Efficient Power Conversion (EPC), which supplies enhancement-mode gallium nitride (eGaN) power devices, has released a high-performance 25 ARMS, 3-phase BLDC motor drive inverter reference design.

Powered by the EPC2304 eGaN FET, the EPC9196 inverter is designed for medium-voltage (96-150 V) battery-powered motor drive applications, including steering systems in automated guided vehicles (AGVs), traction motors in compact autonomous vehicles and precision motor joints in robotics.

The release offers system designers a compact, efficient, and ready-to-deploy solution that accelerates development and optimizes system performance in the lower end of the 25-400 ARMS application range, according to the company. EPC recently introduced its EPC2367 100 V eGaN FET.

The EPC2304 is a 200 V-rated, 3.5 mΩ (typical) eGaN FET in a thermally enhanced QFN package chosen for its low RDS(on) and high performance in compact form factors. It enables the EPC9196 to deliver up to 35 Apk (25 ARMS) phase current at switching frequencies up to 100 kHz. This performance translates to low switching losses, minimal dead time and a smooth, low-noise motor drive profile even at high PWM speeds. EPC said.

Key features of the EPC9196 include a wide input voltage range from 30-170 V, integrated gate drivers, housekeeping power, current and voltage sense, over-current protection and thermal monitoring and dv/dt control optimized for motor drive applications (<10 V/ns). The inverter is compatible with multiple motor drive controller platforms from Microchip, ST, TI and Renesas. It is ready for use in sensorless or encoder-based control configurations.

“With the introduction of the EPC9196, we’re enabling engineers working in robotics, AGVs, and compact EVs to take full advantage of GaN’s superior performance without redesigning for high current,” said Marco Palma, Director of Motor Drive Systems and Applications at EPC.

Source: EPC