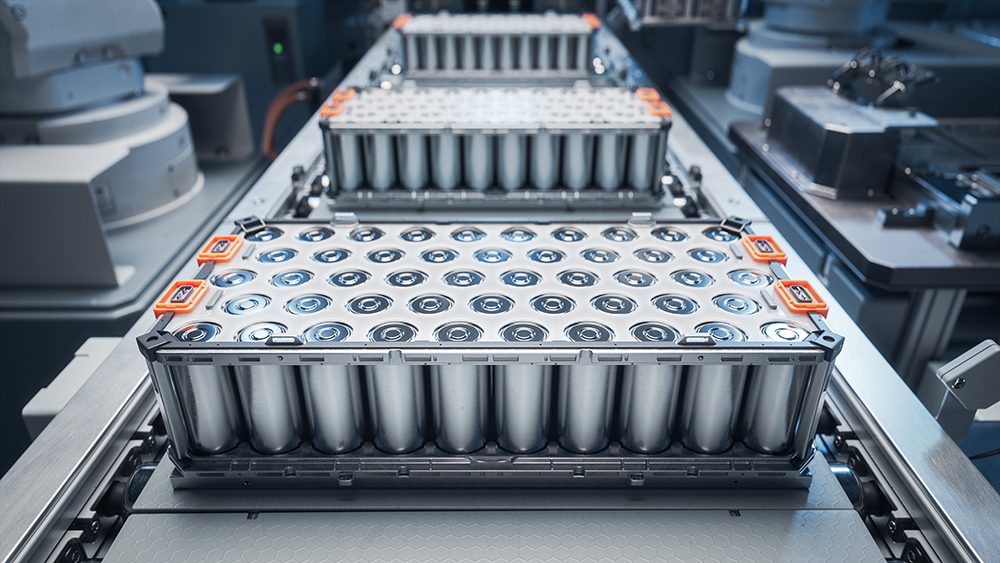

Effective thermal management is one of the most critical aspects of EV battery pack design. Engineers must not only ensure efficient heat dissipation during charging and discharging cycles but also maintain uniform temperature across all cells to optimize performance and extend battery life. This requires integrating advanced materials—such as flame-retardant foams, adhesives, and gap fillers—that can simultaneously control heat flow, provide structural reinforcement, and improve overall safety.

To learn more about addressing these thermal challenges at the material level, Charged recently chatted with Germaine Mariaselvaraj, Technical Service Manager at H.B. Fuller. Germaine explained how their EV Protect foam series addresses a core challenge in EV battery design: preventing thermal runaway from propagating between cells. The foam acts as a fire‐retardant barrier, helping isolate a single failing cell so that the rest of the pack remains intact. Beyond just safety, it also delivers structural and vibration-resistance benefits, which many battery integrators rely on to meet durability standards without adding heavy metal or plastic stiffeners.

H.B. Fuller’s first offering, EV Protect 4006, is a semi-structural foam that flows into cavities and expands to encapsulate components. As market demands shifted toward more structural solutions, H.B. Fuller introduced EV Protect 5006, 5008, and 5009—versions with increased stiffness that allow for the reduction or replacement of traditional structural parts. The upshot: reduced part count, lower mass and a more integrated pack layout that supports newer architectures like cell-to-pack or cell-to-chassis.

Beyond thermal management, the foam contributes to noise, vibration and harshness (NVH) control and thermal insulation. Some customers rely on the foam to help them pass vibration testing that they could not achieve with bare components, and because the foam envelops the cells, it also mitigates temperature swings in extreme ambient conditions. In cold or hot environments, the foam moderates local temperatures, helping reduce the impact on range or battery performance.

Germaine also discussed H.B. Fuller’s EV Bond 775, a reactive hot-melt adhesive that streamlines battery module assembly. By replacing tape or multi-step adhesive processes, this reactive hot-melt enables faster bonding of mica to lids, cells and cooling tubes. That accelerates cycle time, reduces handling, and cuts scrap or rework—all valuable in high-volume battery manufacturing.

On the gap-filling and thermal interface front, H.B. Fuller’s EV Them 288 (a silicone-free MS polymer) competes with traditional silicone gap fillers. Because it’s silicone-free, it helps meet stricter OEM constraints on materials in the manufacturing environment.

Learn more about H.B. Fuller’s battery pack materials portfolio https://www.hbfuller.com/ev.