Energy Fuels, a US producer of rare earth elements and other critical minerals, has announced that high-purity neodymium-praseodymium (NdPr) oxide produced at its White Mesa Mill in Utah has been manufactured into commercial-scale rare earth permanent magnets for drive unit motors used in EVs.

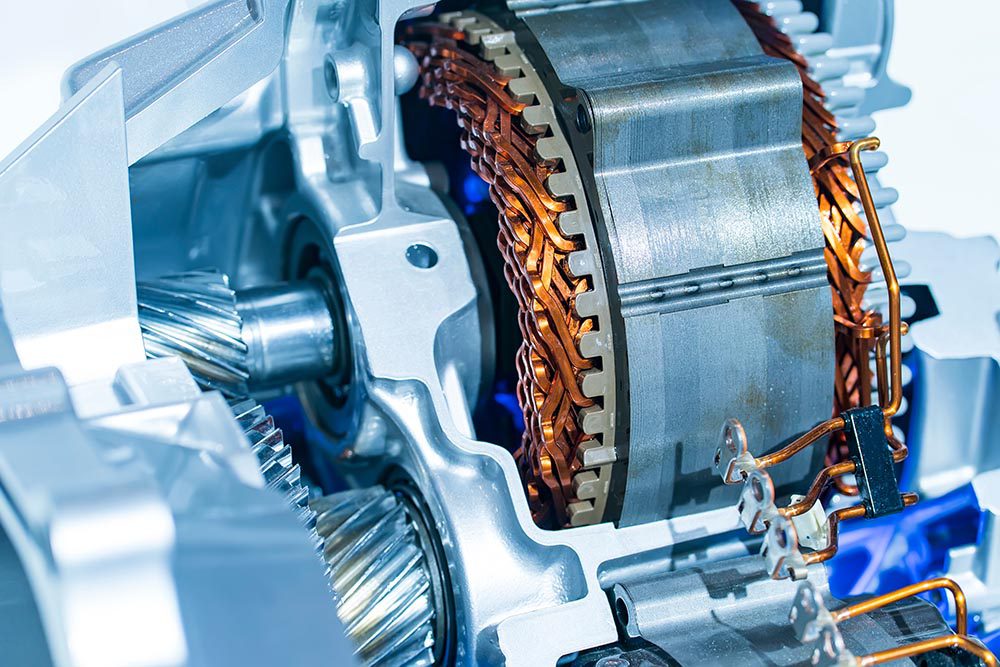

The permanent magnets were produced a South Korean manufacturer of drive unit motor cores, and have passed quality assurance and quality control benchmarks for use in EV drive unit motors sold to major automotive manufacturers.

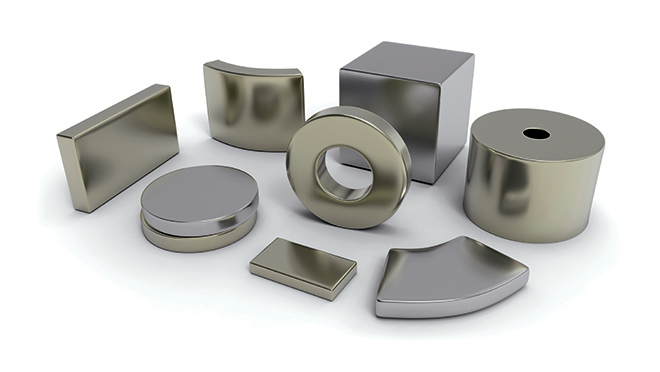

This included the manufacture of Energy Fuels’ NdPr oxide into NdPr metal, neodymium-iron-boron (NdFeB) alloy sintered blocks (45H grade), and high-performance, high-temperature NdFeB REPMs.

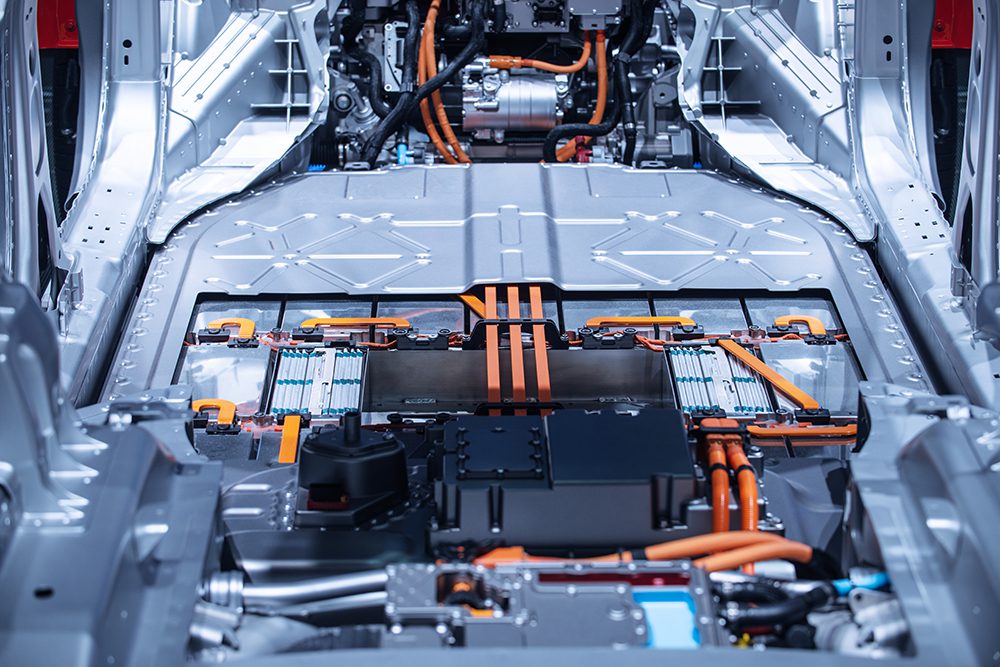

The 1.2 metric tonnes of NdPr oxide supplied by Energy Fuels earlier this year was processed into approximately 3 metric tonnes of permanent magnets, enough to power approximately 1,500 new electric and hybrid vehicles.

The oxides that Energy Fuels produced were derived from monazite concentrates mined in Florida and Georgia at heavy mineral sand (HMS) operations owned and operated by Chemours.

The company’s NdPr oxide has now been qualified for use in high-temperature drive units, which are installed in EV and hybrid vehicles manufactured by automotive companies in North America, the EU, Japan and South Korea.

Drive units powered by the company’s NdPr oxide are expected to be installed in new vehicles and be available in the marketplace within the next few months, the company said. Now that the NdPr has been validated, Energy Fuels intends to engage in negotiations with the manufacturer for a potential longer-term supply arrangement.

“Rare earth oxides mined, processed and produced in America are expected to be powering EVs and hybrids for sale around the world very soon, representing a major achievement in restoring domestic critical mineral supply chains,” said Mark S. Chalmers, CEO of Energy Fuels. “Energy Fuels also recently announced that we are producing pilot quantities of 99.9% purity dysprosium oxide, a critical heavy rare earth and another key ingredient in NdFeB magnets. We plan to construct heavy rare earth oxide capacity in 2026 at our White Mesa Mill in Utah, thereby closing the loop on this important non-China supply chain.”

Source: Energy Fuels