US battery recycling firm Ecobat has commissioned three lithium-ion battery recycling facilities within a year.

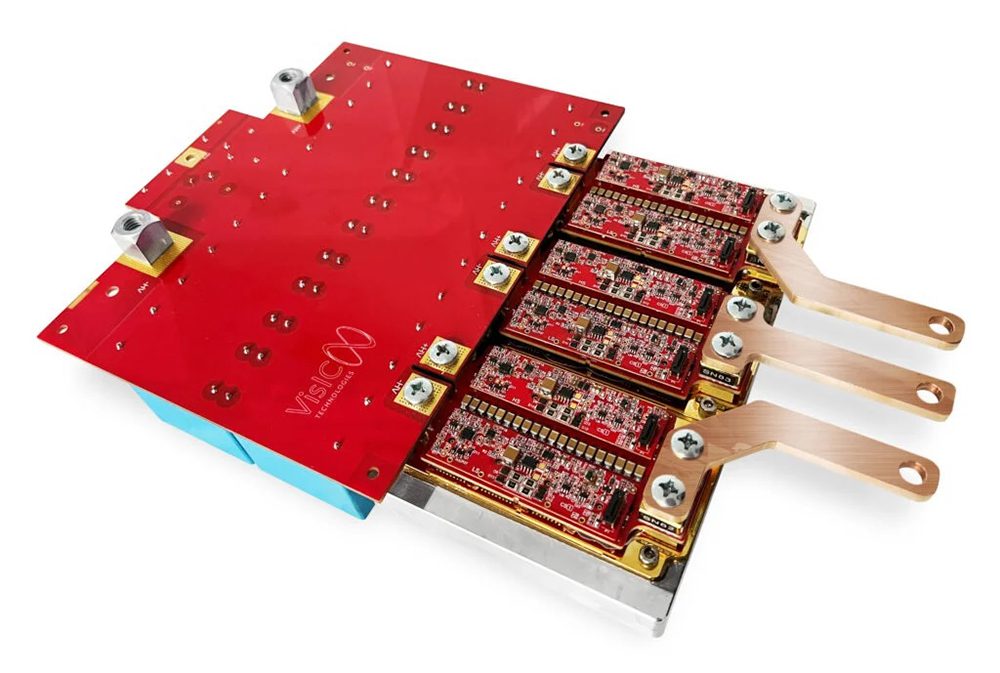

Located in Hettstedt, Germany; Casa Grande, Arizona and Darlaston, England, the facilities are fully operational and capable of processing up to 10,000 tons of lithium-ion batteries annually. The company plans to scale the capacity up to 25,000 tons.

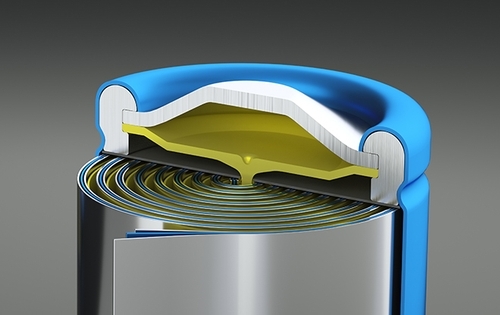

The plants focus on the production of black mass, the critical material derived from recycled lithium-ion batteries, which is rich in essential minerals such as lithium, cobalt, nickel, manganese and graphite.

The Hettstedt, Germany plant, commissioned in the fourth quarter of 2023, processes a variety of batteries, including EV packs, portable electronics, e-bikes and power tools. The facility serves automotive OEMs and collection programs across Europe.

The Casa Grande, Arizona facility, commissioned in April 2024, works directly with automotive OEMs, battery manufacturers and e-waste recyclers to support the emerging lithium-ion battery recycling infrastructure in the US.

The Darlaston, England plant, commissioned in November 2024, serves as a hub for Ecobat’s operations across the UK and the wider European market and process a range of lithium-ion battery types. The facility also provides diagnostic services and supports sustainable material flows in the British supply chain.

“Ecobat’s rapid expansion in lithium-ion battery recycling demonstrates our commitment to meeting the growing demand for sustainable, closed-loop production processes,” said Brett Horton, Managing Director of Ecobat Solutions. “As EV sales are rising and more end-of-life batteries enter the market, our new facilities are well-positioned to meet these challenges, creating value for our partners and stakeholders, while helping to drive the transition to a circular economy.”

Source: Ecobat