Sponsored by HBM Test and Measurement

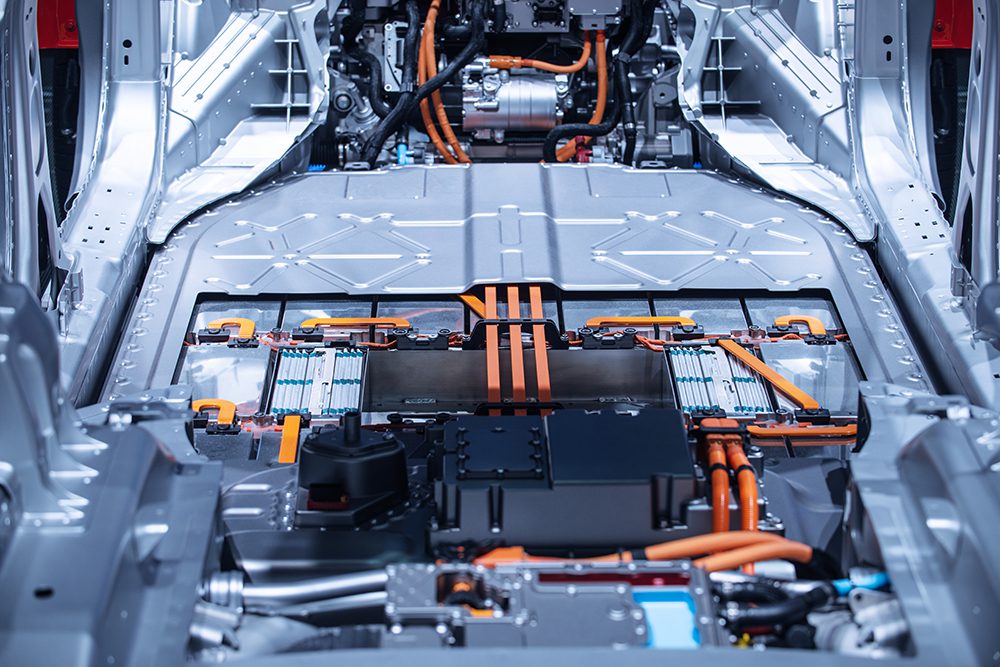

In-vehicle testing provides engineers with a method to benchmark competitors’ vehicles, calibrate drivetrains, and validate the performance of the product. In the emerging electric vehicle market, electrical power measurements on motors and inverters are becoming necessary to evaluate the powertrain of the vehicle. Previously, mobile power measurements were difficult due to the dynamic nature of the vehicle which is constantly changing speed. However, unique features provided in HBM’s electric drive solution, a system for testing electric machines and drives, make mobile electrical power measurements possible in real-world environments.

This paper will discuss the need for in-vehicle testing, power measurement challenges, and the limitations of traditional power analyzers. It will also cover how eDrive performs dynamic power measurements and publishes cycle-based calculations to a CAN bus for correlation to an existing DAQ system. The paper will conclude with a series of dynamic power measurement examples where the eDrive is used to test the motor system in an electric scooter. These measurements demonstrate how motor and drive performance can be assessed during vehicle acceleration and deceleration, coasting and other conditions as well as test motor control techniques.

Topics covered in this paper include:

- The benefits of measuring on a vehicle

- Unique challenges of testing mobile power and efficiency

- What makes traditional solutions impossible or inaccurate

- Applying faster, continuous sampling

- The importance of dynamic power

- Signal correlation

- Dynamic power measurement example

- Vehicle acceleration and dynamics

- Regenerative braking

- Dynamic control examples

Find out more about dynamic motor power measurements and the impact on in-vehicle testing of EVs.