DuPont has introduced a new adhesive, BETASEAL TC, for EV and hybrid battery assemblies. The material is designed to ensure retention of thermal conductivity between battery cells and cooling plates by creating a strong, long-lasting contact with no gaps.

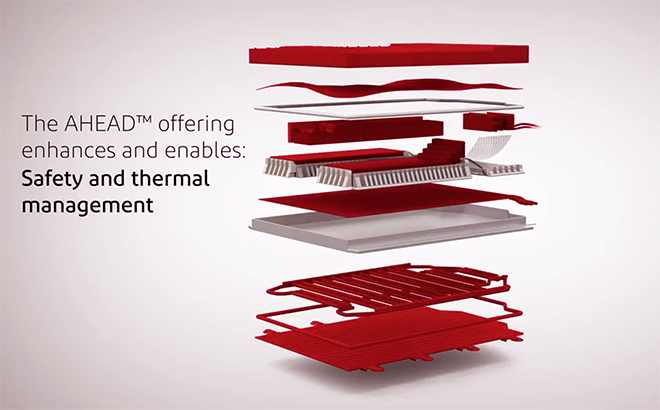

DuPont says that BETASEAL TC, part of its AHEAD (Accelerating Hybrid-Electric Autonomous Driving) initiative, has a range of benefits over existing adhesives, including a 30-minute working time, low pullout force for easy battery module removal, and a non-abrasive formula. DuPont also says the product shows no sagging in vertical aging tests or any other physical changes during aging. The material is compatible with fast dispensing, compression, and injection processes and can be robotically applied for high-volume applications or manually applied for smaller volumes or repairs.

“Adhesive solutions are in our DNA. We bring nearly 75 years’ experience to the automotive industry and we are translating that expertise to serve the growing hybrid and electric vehicle market,” said DuPont R&D Director Andreas Lutz. “BETASEAL TC is just one of many component and assembly solutions brought to the industry by DuPont.”

Source: DuPont