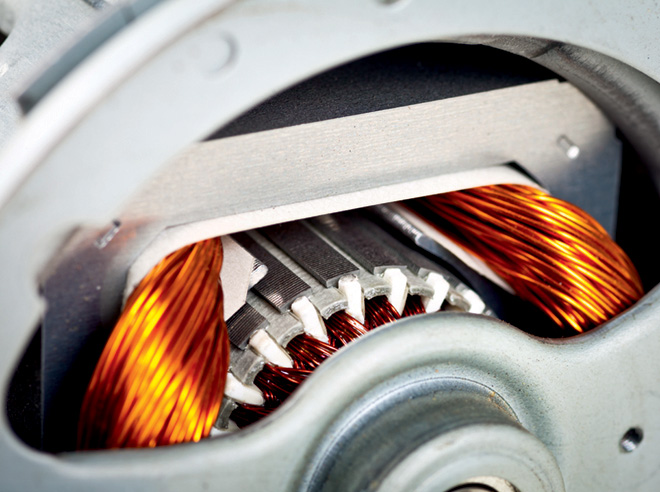

The DOE’s Argonne National Laboratory has invented a new magnet technology, called HyMag, which could lead to greater efficiency and lighter weight in EV and hybrid motors.

HyMag increases a permanent magnet’s usable magnetic flux density, a property of permanent magnets that can be harnessed for power generation. “The higher the flux density you use for power generation, the more energy you generate,” said Argonne Group Leader Kaizhong Gao. “You have to have higher flux density in order to have more efficiency.”

In the 1990s, conventional permanent magnets composed of neodymium, iron and boron became widespread, yet they resisted efforts to improve performance, said Zhang.

“In the past 15 to 20 years, the increase in magnet energy products reached a plateau due to lack of material solutions,” said Zhang. Researchers have looked into various ways to improve the composition, microstructures, and processes of existing magnetic materials. Each could lead to a small improvement of the magnet’s energy product. However, the magnetic flux of a magnet decays rapidly with distance, which makes the use of magnetic flux insufficient.

Gao and fellow Argonne inventor Yuepeng Zhang have improved permanent magnet performance by combining hybrid layers of material in a way that reduces the flux leakage.

When designed properly, the gain in the magnet’s usable flux density ranges from 10 to 30 percent, depending on the application and working temperatures, said Gao and Zhang.

HyMag could especially benefit weight-sensitive applications because the technology’s higher efficiency could lead to downsized structures.

On top of the greater efficiency and weight shedding, in certain applications, HyMag technology may require up to 90 percent less (by weight) rare-earth elements, such as dysprosium and gadolinium, than regular magnets with similar performance.

These elements, mostly imported from China, can be scarce, expensive and difficult to recycle. According to Gao and Zhang, a typical vehicle traction motor contains approximately a tenth of a kilogram of dysprosium.

Source: Argonne National Laboratory