Southwire is using its decades of electrical engineering experience to support the growing demands of electric vehicle infrastructure. Recently, Charged spoke with Yuhsin Hawig, Vice President of Applications Engineering at Southwire, about the company’s evolving role in the e-mobility space. With over 75 years in the electrical industry and more than 15 years focused on EV solutions, Southwire is well-positioned to support utilities, fleets, and commercial developers as they adapt to electrification requirements.

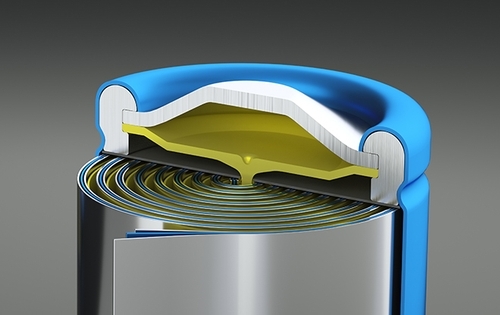

A major area of focus for Southwire is the custom design of EV charging cables. Hawig explained that more than 20 design parameters—such as copper conductor type, insulation material, shielding, and jacketing—can be configured to meet specific customer needs. Approximately 95% of Southwire’s EV charging cables are built to project-specific requirements, highlighting the tailored nature of EV infrastructure deployments across different geographies and use cases.

To support engineers, contractors, and specifiers, Southwire offers a suite of free online tools. Its conduit fill and voltage drop calculators are among the most utilized, helping professionals meet National Electrical Code standards. According to Hawig, these tools collectively draw over a million users annually and play an important role in streamlining both pre-sales planning and post-sales implementation. The company’s building wire selector was also recently recognized by industry peers for helping users select wire products based on application needs.

Sustainability has installed solar-powered EV charging stations at its headquarters in Carrollton, Georgia, and its distribution facility in California. A larger solar installation is underway at its North Campus facility in Georgia, expected to deliver 5 megawatts of DC electricity—enough to cover 20% of the plant’s energy consumption. Southwire also publishes Environmental Product Declarations (EPDs) for over 100 product types, providing transparent data about the lifecycle impact of its cable offerings.

Southwire’s Cable-in-Conduit (CIC) solution combines power cables and conduits into a single preassembled product, enabling easier and faster installation for EV charging stations, utility work, and renewable energy projects. These assemblies use HDPE (high-density polyethylene), a hydrophobic and lead-free material that enhances durability and resistance to moisture and wildlife damage. Hawig noted that projects using CIC can reduce cable installation labor by up to 30%, offering a practical advantage for large-scale deployments.

With the EV landscape evolving rapidly, Southwire’s engineering team works closely with customers to develop cable systems that meet technical, environmental, and regulatory needs. As Hawig explained, designing an EV charging cable requires balancing multiple physical, mechanical, and chemical factors. Through a mix of engineering tools, sustainability initiatives, and customizable products, Southwire is contributing to a more adaptable and efficient EV infrastructure ecosystem.

Learn more:

https://www.southwire.com

https://www.southwire.com/calculators

https://www.southwire.com/sustainability/product-transparency