Critical Materials Recycling (CMR) and Paladin EnviroTech have formed a new joint venture, REcapture, focused on recycling rare earth elements (REEs) from consumer, automotive and industrial electronics.

The partnership merges CMR’s processing capabilities for material recovery with Paladin’s environmental technology platform and global collection network.

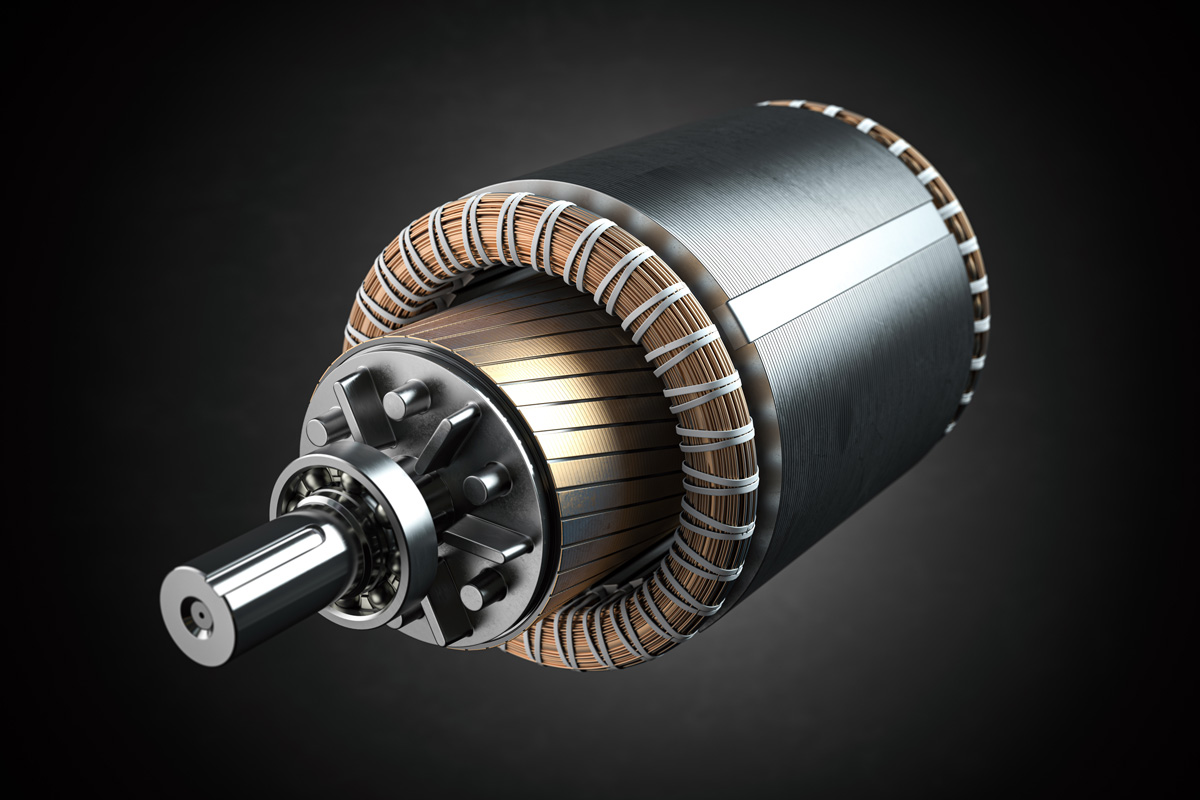

CMR’s scalable technology, which was originally developed at Ames National Laboratory, recovers rare earth oxides including neodymium, praseodymium, dysprosium and terbium from end-of-life devices such as motors, speakers, hard drives and other electronic components.

The first REcapture collection systems are already operating across North America, servicing key industrial and consumer electronics recycling networks. Expansion plans include partnerships with manufacturers, recyclers and other stakeholders to increase the rate of rare earth material recycling.

“Our mission with REcapture is simple yet transformative: to make rare earth recycling as accessible and impactful as ferrous or copper recycling,” said Dan Bina, CEO of CMR and Co-Chair of REcapture. “By integrating our recovery technology with Paladin’s collection and processing systems, we can divert strategic materials from waste streams and reduce reliance on foreign supply chains.”

“REcapture is a natural evolution of our work,” said Brian Diesselhorst, CEO of Paladin and Co-Chair of REcapture. “By combining CMR’s rare earth recovery expertise with our sourcing, collection and processing capabilities, we’re delivering a practical, data-driven solution to one of the most pressing resource challenges of our time.”

Source: Paladin EnviroTech