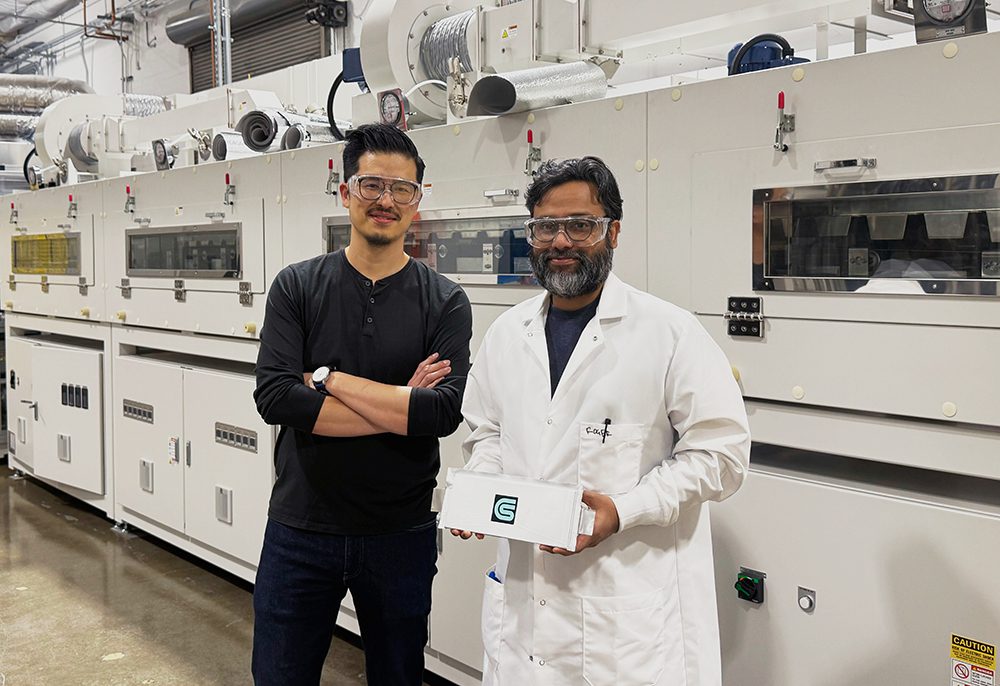

Battery technology company Coreshell has raised $24 million in funding to scale the production of its 60 Ah battery cells made with domestically-sourced metallurgical silicon.

The funding round was led by Ferroglobe, a London-based producer of silicon and ferroalloys, and California-based venture capital firm Zeon Ventures. Other investors included Lane Ventures, Entrada Ventures, Foothill Ventures, Helios Climate Ventures, Translink Investment, Trousdale Ventures and Asymmetry Ventures.

The company operates a new 4 MWh manufacturing plant in San Leandro, California, and is in the process of site selection and design for another 100 MWh facility. It expects to begin delivery of commercial samples of its battery cells to automakers this year.

Coreshell says it has made a breakthrough in cell design by producing batteries using abundant unrefined metallurgical silicon anode material at half the cost of graphite; this results in around 30% greater range, lighter weight and cost reduction of up to 25%. Serial production cells are expected to exceed 1,000 cycles to 80% of original capacity.

“As the global EV industry reaches an inflection point,” said Coreshell CEO Jonathan Tan, “automakers recognize that alongside range, supply chain resilience—driven by reliance on foreign countries for graphite production—and cost reduction are key to overcoming adoption barriers. Coreshell is addressing these challenges by replacing graphite with domestically sourced metallurgical silicon.”

Source: Coreshell