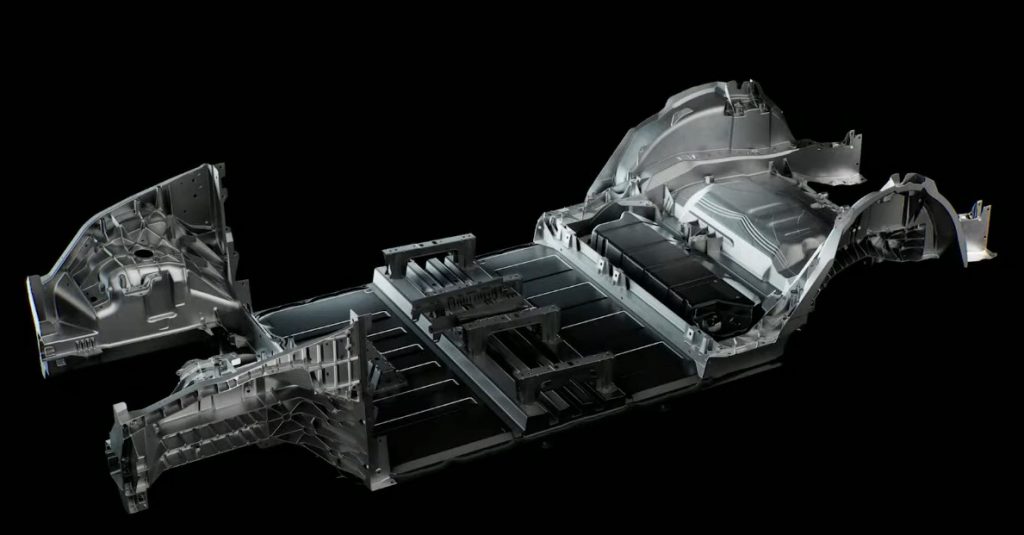

Tesla’s megacasting technique—using giant casting machines to make car bodies with just a few massive cast parts—greatly reduces the complexity of the body assembly process, saving costs and improving efficiency. Tesla is producing Model Y at Gigafactory Texas using an enormous Giga Press to cast a single rear body piece, which replaced 70 different parts.

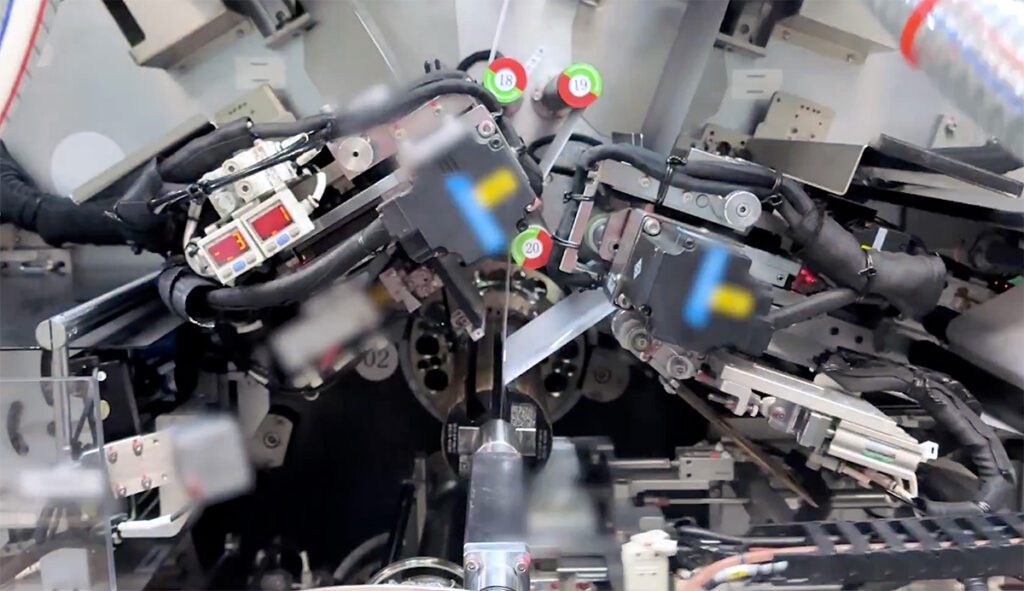

The Giga Presses Tesla is using in Texas are made by an Italian company called IDRA. In 2019, Tesla commissioned what it called the world’s largest casting machine from a Chinese manufacturer, the LK Group, and it’s believed that this will soon go into service at Gigafactory Shanghai.

LK Group founder Liu Siong Song recently told the New York Times that his company worked with Tesla for over a year to make the massive new machine. LK will also supply similar giant casting presses to six Chinese companies by early 2022.

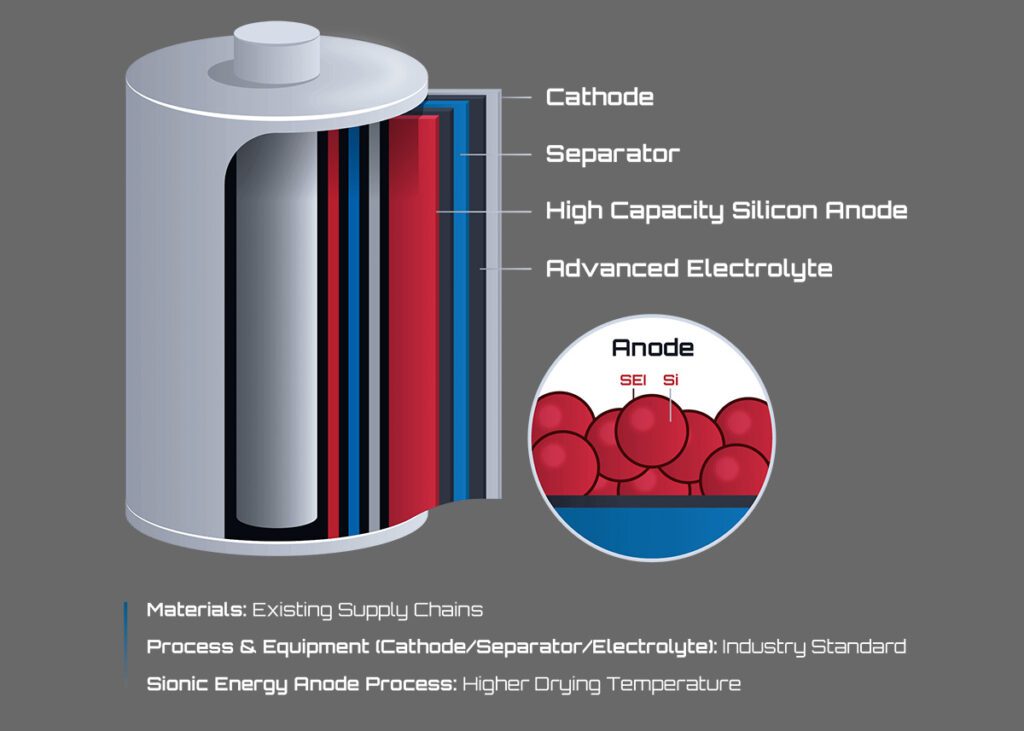

The adoption of Tesla’s megacasting process by other automakers is just one dramatic example of the mutually-beneficial relationship between Tesla and China’s rapidly emerging EV industry. The Chinese government has rolled out the red carpet for Tesla, granting it unprecedented access to the world’s largest auto market, and streamlining regulatory approvals to get Gigafactory Shanghai built in record time.

In turn, Tesla is helping Chinese companies become ever more competitive, working with local suppliers to make increasingly sophisticated components that enable them to challenge the automotive giants of the US, Europe and Japan.

Gigafactory Shanghai has been very good to Chinese component suppliers. Tesla says that, in the fourth quarter of 2020, some 86 percent of outsourced Model 3 and Model Y components used at the Shanghai Gig came from within China. (For cars made in Fremont, 73 percent of outsourced components came from China.)

The Times speculates that Tesla could do for Chinese EV-makers what Apple did for the country’s smartphone industry. As iPhone technology spread to local companies, they began making better and better phones, and some of them have gone on to become major players in global markets.

LK hopes to sell its megacasting machines to many more Chinese companies, but Mr. Liu told the Times that local automakers lack the talented car designers that Tesla has in plenty. “Many Chinese automakers are talking to us about building the machines, but the majority of them are still in the design process. We have a bottleneck in designers in China.”

Sources: New York Times, Electrek