At its largest European manufacturing location in Dingolfing, Germany, BMW recently opened the Competence Centre for E-Drive Production. Having produced electric powertrain components in Dingolfing since 2013, the BMW Group is now expanding its capacity.

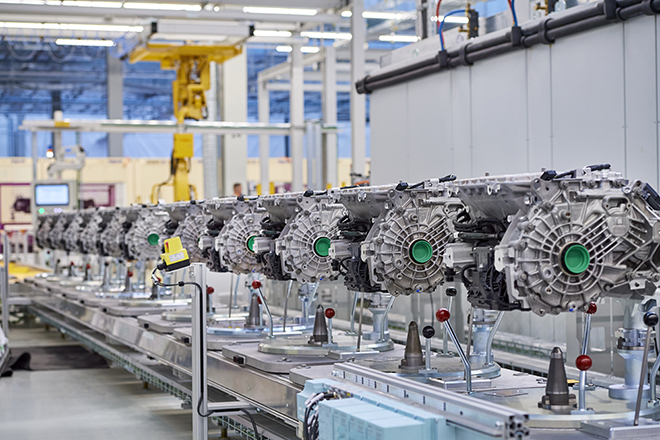

Bavarian Minister-President Markus Söder and Chairman of the Board Oliver Zipse symbolically launched the production of the new, highly integrated BMW e-drive, which combines the electric motor, transmission and power electronics in a central housing. The new generation of the BMW e-drive will be used for the first time in the new BMW iX3, which will go into production in China in late summer.

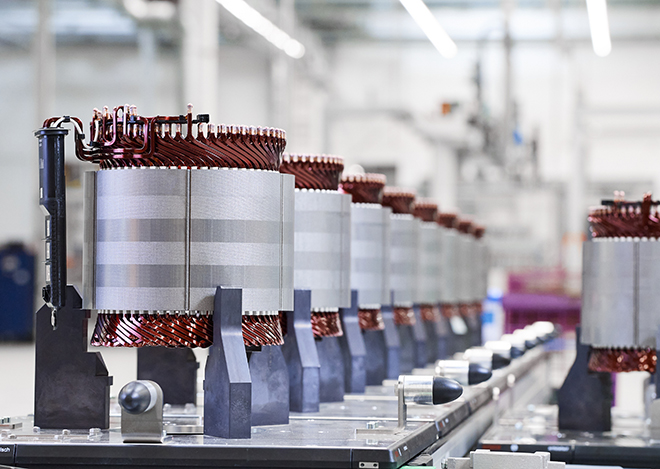

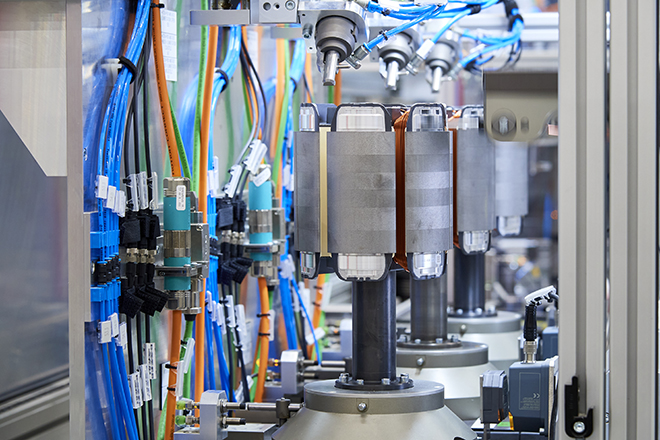

At the Competence Centre in Dingolfing, the BMW Group will produce electric powertrain components such as battery modules, high-voltage batteries and electric motors on eight production lines. Over the coming years, the company will set up four additional lines.

Chairman Zipse said, “By 2022, in Dingolfing alone, we will be able to produce e-drives for more than half a million EVs per year. At the same time, we will produce a mix of fully-electric vehicles, plug-in hybrids and models with a combustion engine on a single line, as required by demand.”

In the next few years, the Competence Centre’s production area will be expanded to ten times the original size: from 8,000 square meters in 2015 to 80,000. The number of employees will also be increased. In the first half of 2020 alone, the workforce grew from 600 to 1,000. Up to 2,000 employees will work in the production of e-drives at the Dingolfing location in the medium term.

“Our unique expertise in producing high-voltage batteries and electric motors ensures our technology is always state of the art, and we are able to ramp up production quickly and systematically in line with demand,” said Michael Nikolaides, head of Planning and Production Engines and E-Drives. A quarter of BMW Group vehicles sold in Europe should have an electric drivetrain by 2021; a third in 2025 and half in 2030. By 2023, the BMW Group will offer its customers no fewer than 25 electrified models, around half of them with pure electric drivetrains.

On the same day as the official opening, the Competence Centre also began production of the fifth-generation electric drivetrain. This highly integrated electric powertrain component combines the electric motor, transmission and power electronics in one housing. According to BMW, rare earth materials are no longer required.

Source: BMW