Canadian automated testing firm Averna has developed a procedure for automating battery inspection for one of its customers using Germany-based MVTec’s HALCON machine vision software.

The procedure is designed to identify a variety of external product faults and precisely pinpoint their location before the batteries leave the factory. The inspection takes place before the labeling process to ensure that only fault-free products are labeled and approved for shipping. The aim is to improve quality, increase customer satisfaction and reduce overall costs.

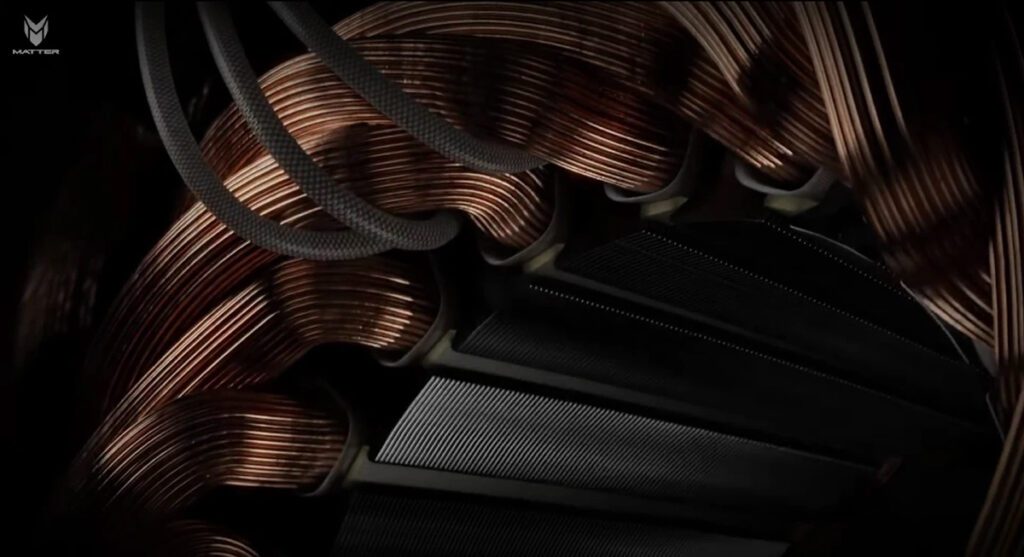

Averna integrated HALCON into its Averna own software on a real-time engine to analyze a large number of images recorded at high speed to quickly determine and electronically communicate the position of the test object. Each image includes multiple batteries so that the inspection time can be minimized through simultaneous viewing. Multiple cameras record the batteries from every angle, generating nearly 10,000 images per minute.

The lighting is designed so that defects appear in the image as shadows at a higher contrast, making scratches, discolorations, and other types of anomalies easily recognizable. Three Gardasoft controllers regulate the timing of the light precisely and intensify it by up to 300% for brief 20-μs intervals.

The battery is then either rejected as defective or, if no faults are found, forwarded for labeling. A digital, high-speed I/O system communicates the inspection results to the controller and the products are sorted automatically. The system can also be integrated seamlessly into existing fieldbus technologies like EtherCAT.

“Speed was the top priority for this application because production processes must not be delayed by a time-consuming screening procedure,” said Roel Geraerts, Team Leader, Vision at Averna. “Because a 360-degree approach involves inspecting batteries from all sides, powerful technologies for lighting and handling were needed. In close collaboration with the customer, specialists at Averna developed a sophisticated solution consisting of high-quality cameras and lighting systems mounted on a conveyor belt. The powerful light beams are aimed directly at the battery at optimal angles for making the smallest discrepancies in the battery’s surface visible.”

Source: MVTec Software