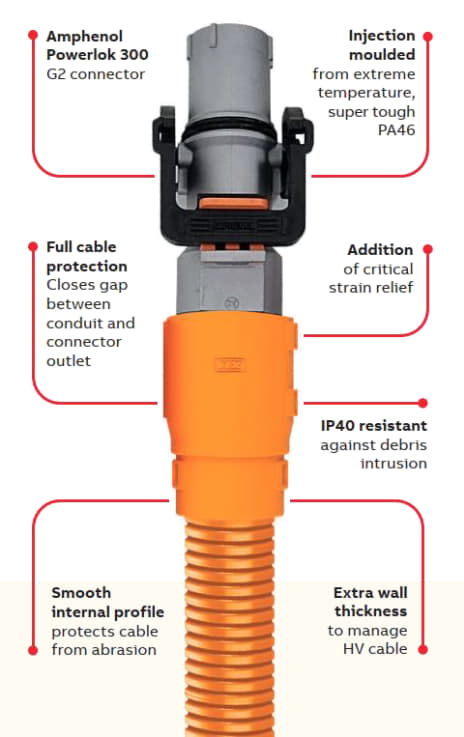

Cable-to-connector stability is critical to the operation of any EV. Heavy-duty EV wiring is particularly vulnerable to high engine temperatures, strain, abrasion, vibration, ingress and corrosion. To protect and stabilize these connections, ABB Installation Products has introduced a full range of hinged high-voltage connector backshells.

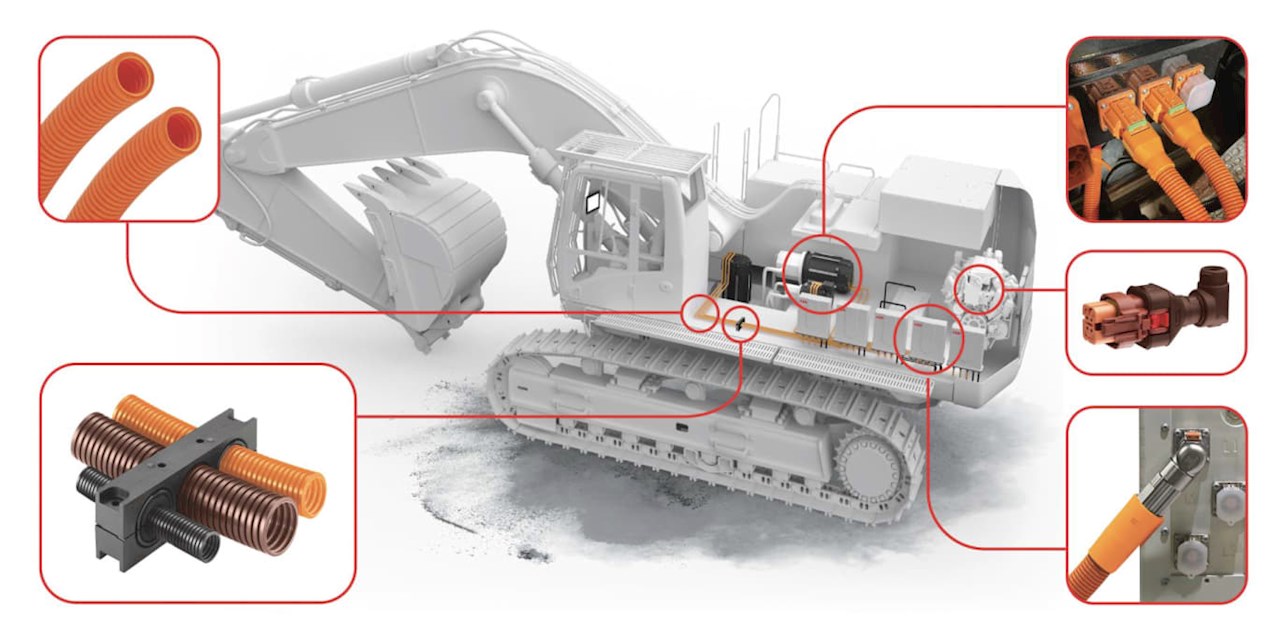

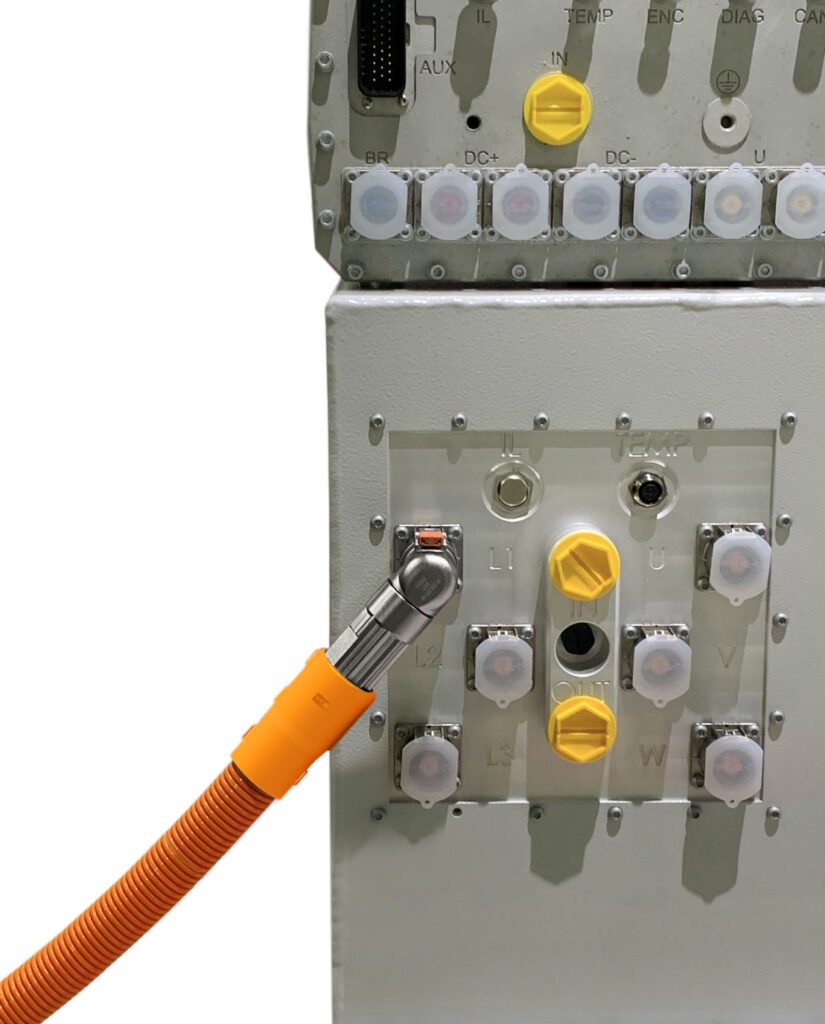

ABB’s new Harnessflex EVO Connector Interfaces are part of a complete cable protection system designed to meet or exceed industry standards, protect critical wiring, and improve performance and reliability in high-voltage applications.

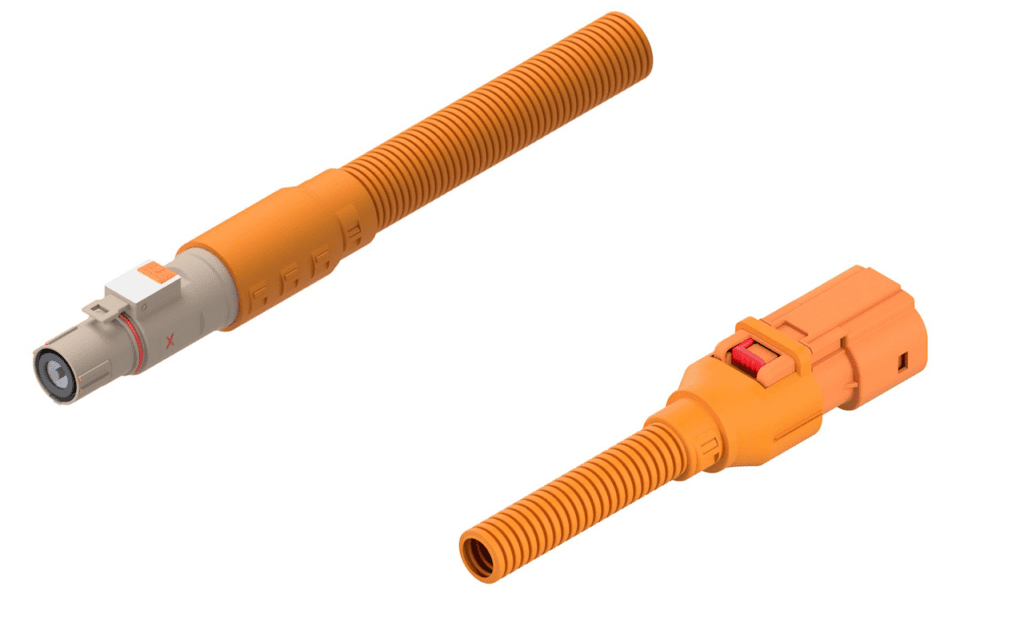

The Electric Vehicle Orange color of ABB’s Harnessflex EVO Connector Interfaces indicates high-voltage wiring and components. The interfaces are designed to deliver cable-to-connector strain relief with high mechanical performance, and to prevent debris intrusion.

“ABB is working with vehicle makers, transportation providers and OEMs to integrate robust electrical wiring solutions that meet evolving requirements, while delivering safer and reliable performance,” said ABB Installation Products EVP Andrea Castella. “Harnessflex EVO Connector Interfaces offset the need for expensive, bulky cable clamps in high-voltage applications, and expand ABB’s electrification solutions for a broad range of demanding areas of transportation, from construction and agriculture to trucks, buses and trains.”

“ABB’s first-of-its-kind Harnessflex EVO Connector Interfaces reduce cable movement and form tighter junction joints for safer and more secure high-voltage connections in electric ancillaries, DC/DC converters, onboard chargers, high-voltage battery packs, hybrid systems, hydrogen fuel cell vehicles, and dynamic and static power systems,” notes Nathan Cook, Global Business Development Manager for Cable Management Products.

Source: ABB Installation Products