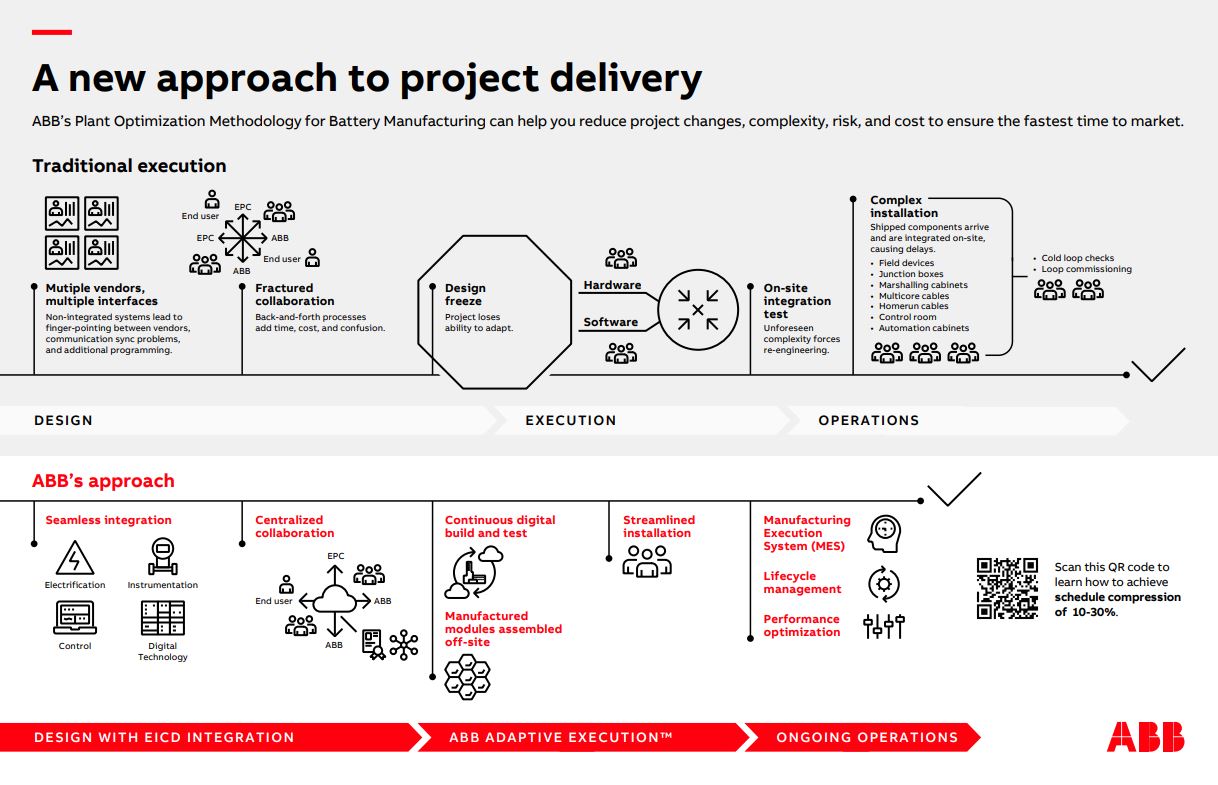

ABB has introduced a new “modular and repeatable” manufacturing methodology designed to facilitate the establishment of new battery plants.

ABB’s Plant Optimization Methodology uses electrification, instrumentation, control and digital technology (EICD), the ABB Adaptive Execution project approach, and continual operational support to help battery manufacturers establish new plants and scale up gigafactories.

“The methodology leverages the value of early collaboration, through ABB’s Adaptive Execution, to optimize plant design and performance by helping to minimize greenfield site project changes,” says ABB. “In doing so, it compresses manufacturing schedules, reduces start-up hours and delivers CapEx and OpEx savings.”

“Unlike traditional approaches, which can have multiple vendors and interfaces, on-site integration and complex installation, ABB seamlessly integrates EICD technology with centralized collaboration and streamlined processes to optimize operations,” says the company.

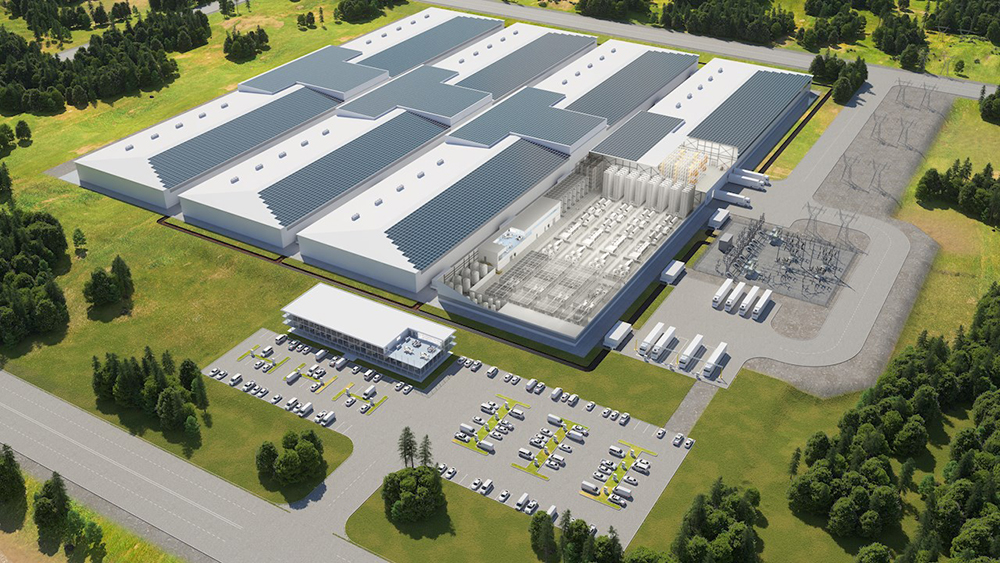

ABB says it is working with battery manufacturer Northvolt on its sustainable manufacturing base.

Source: ABB