Researchers at Freudenberg are developing a plastic housing material for EV electronics as an alternative to heavier and more costly aluminum.

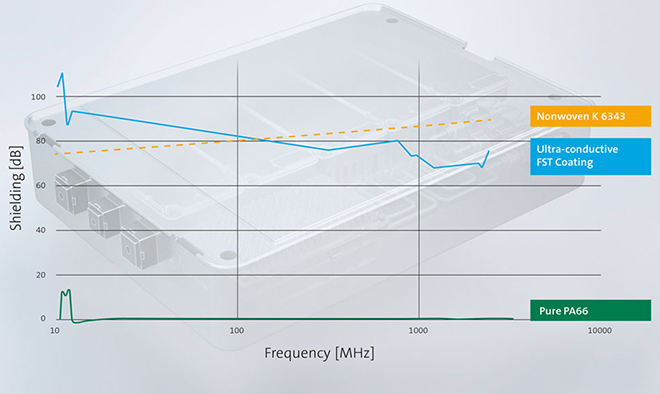

To protect against electromagnetic waves that can disrupt signal flow in microprocessors and transmitter-receiver systems, EV makers typically encase electrical components in conductive metal housings, usually aluminum. Freudenberg says the additional weight of the aluminum impairs driving dynamics and vehicle range and increases vehicle cost. To solve this issue, researchers at Freudenberg are developing processes that can equip lighter-weight plastics with conductive coatings or nonwovens. Freudenberg says that early lab tests show values for its new electromagnetic shielding up to 99.99999%.

The company has developed two approaches to shielding in the frequency range of 150 kHz to 100 MHz, a spread that Freudenberg notes is particularly important for EV drivetrains. The first material is designed to deflect electromagnetic waves. The second material weakens the electromagnetic waves at high frequencies, in a process known as absorption.

To deflect electromagnetic waves, the company has developed a nonwoven that is treated with a special galvanic process. It totally encases individual nonwoven fibers with a copper surface, covered by another material layer to prevent corrosion. The nonwoven weighs just 60 grams per square meter, less than typical printer paper. Freudenberg says that, combined with a lighter-weight plastic carrier material, the nonwoven can lead to weight savings of up to a third compared to aluminum , equal to about a 5-kilogram reduction in the weight of a battery housing cover.

For the shielding of fairly small components, Freudenberg has developed coatings that deflect electromagnetic waves from surfaces. The plastic component is coated with an aqueous dispersion in which the plastic matrix contains a conductive filler. Freudenberg notes that neither the coating nor the nonwoven impairs the mechanical properties of the plastic component, a crucial feature for EV components that could be damaged in an accident, like the battery.

Freudenberg Chairman Claus Möhlenkamp said, “We are working together to simplify the path to the era of electric mobility.”

Source: Freudenberg