Germany-based Freudenberg Sealing Technologies has developed a new, highly compatible elastomer material for automotive applications as an alternative to PFAS-containing thermoplastic and FKM seals. The new material series is processed by injection molding, delivers high-performance sealing, ensures battery life and meets international environmental regulations. “Our O-rings made from the new elastomer prevent electrolytes from leaking out… Read more »

Search Results Found For: "freudenberg"

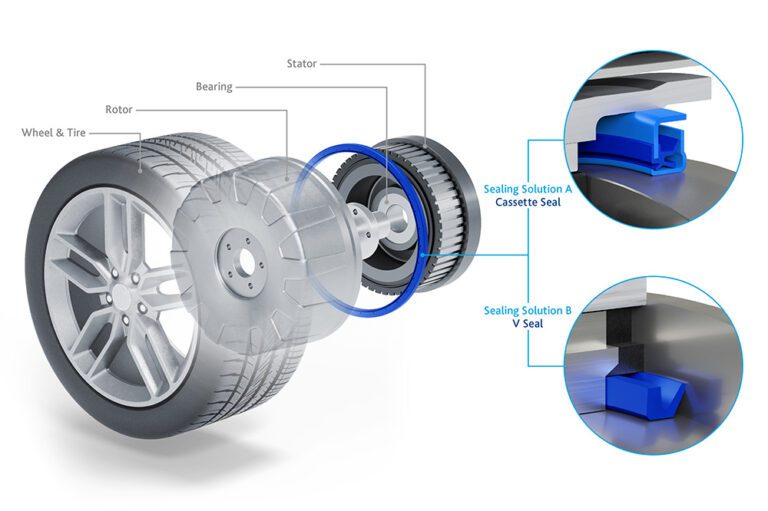

Freudenberg Sealing Technologies develops new seal for in-wheel motors

Germany-based Freudenberg Sealing Technologies offers a sealing geometry to support electric motor manufacturers at the development stage. In-wheel motors for EVs enable wheel-specific torque control, enhanced comfort and more design space within the vehicle. They create a lower center of gravity, tighter turning radius and higher load capacity for electric buses and offer added value… Read more »

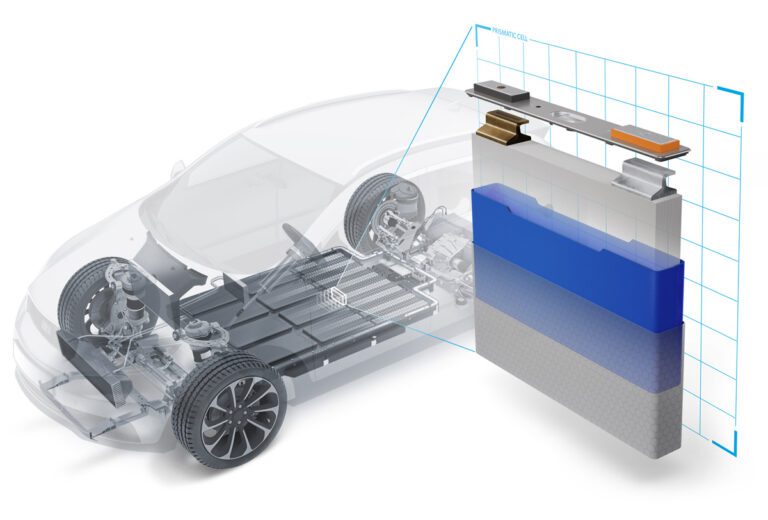

Freudenberg Sealing Technologies launches two new product lines for prismatic battery cells

Germany-headquartered Freudenberg Sealing Technologies has introduced cell caps and nonwoven cell stack envelopes for prismatic battery cells. The battery cell envelopes use nonwoven materials that wrap the cell stack and, like conventional films, protect it during the assembly and provide electrical insulation. Nonwoven envelopes consist of a fiber network forming an ultra-homogeneous pore structure. The… Read more »

Freudenberg Sealing Technologies adds battery testing lab at its Michigan HQ

Freudenberg Sealing Technologies has added a new battery testing laboratory to its R&D labs at its North American headquarters in Plymouth, Michigan. The company says the multi-million-dollar investment will facilitate in-house battery and battery component testing, including simulated thermal runaway, and will increase the company’s functional knowledge and product development capabilities in the field of… Read more »

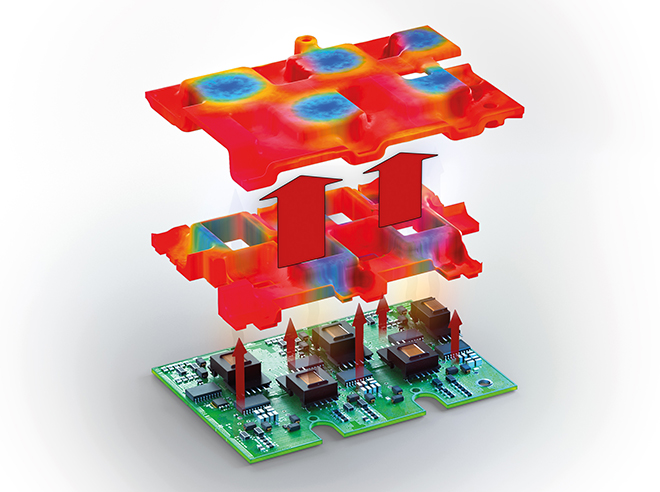

Freudenberg Sealing’s new customized 3D thermal barriers for EV batteries

Thermal runaway—the ignition or explosion of a battery cell caused by a self-reinforcing heating process—can be caused by a range of internal and external factors, such as overcharging, excessive discharging, damage, or heating of the battery. Thermal runaway releases not only flames and hot gases but also electrically conductive particles. These in turn can cause… Read more »

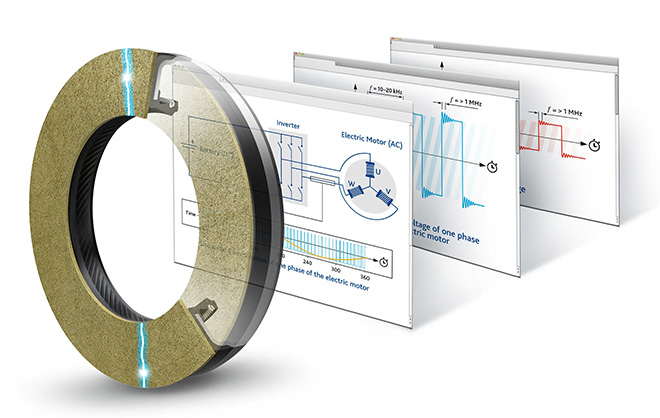

Freudenberg introduces new conductive seals for electric motors

Freudenberg Sealing Technologies is introducing a new generation of electrically conductive seals at the virtual 2021 Vienna Motor Symposium. The seals are designed to prevent bearing damage caused by electrically-induced corrosion and to decrease electromagnetic interference. The power semiconductors in an inverter are often positioned directly above the motor. Silicon carbide semiconductors, which are often… Read more »

Freudenberg expands battery material testing facilities

Freudenberg Sealing Technologies has expanded its material testing capabilities to include performance and compatibility evaluations of the rubber, elastomers and thermoplastics used to seal and safely maintain lithium-ion batteries. The company has installed equipment and adopted new testing protocols in its Plymouth, Michigan Central Laboratory that will provide data on which materials optimally resist breakdown… Read more »

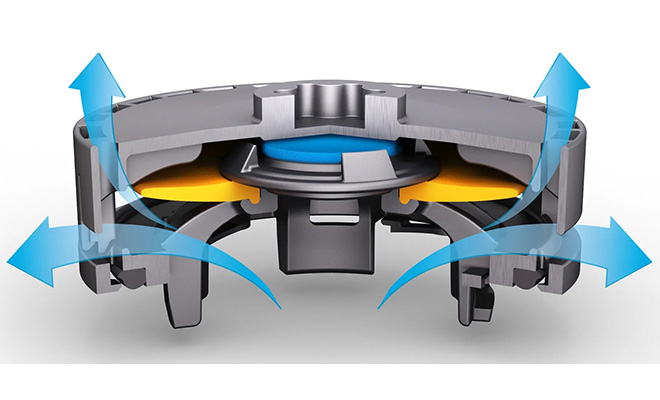

Freudenberg’s new quick-release valves for EV batteries

Freudenberg Sealing Technologies has introduced a new generation of DIAvent valves, which allow reaction gases to escape from damaged lithium-ion batteries. The valves also maintain the continuous pressure compensation required for normal battery operation. If a battery gets damaged, liquid electrolytes can escape into the battery housing as hot gases. These must then be released… Read more »

Freudenberg develops thermally conductive elastomer for EVs

Engineers at Freudenberg Sealing Technologies have developed an elastomer that merges relatively high heat capacity with electrically insulating properties by combining silicone rubber with special fillers. Electronic components can be mounted in a thermally conductive aluminum housing, which dissipates heat through cooling water or convection. Senior Application Manager Armin Striefler explains why Freudenberg decided to… Read more »

The battery that breathes—Freudenberg’s pressure compensation system

EV batteries require pressure compensation both under normal operation and during emergency ventilation. Freudenberg Sealing Technologies’ DIAvent component combines these two functions into a single design, which will be used in the ABT e-Caddy and ABT e-Transporter, two Volkswagen vans that are popular in Europe and Mexico. To reduce battery weight and size, ABT uses… Read more »