With its integrated electric propulsion systems spreading across the globe in all conceivable vehicle types, UQM Technologies could be called the biggest little company in the EV industry. Over the past few years, the company seems to have entered its prime, as in one of those TV commercials where a deep, authoritative voice tell us “life begins at 40,” and a sturdy middle-aged man with salt-and-pepper hair stacks lumber into the back of a pickup truck.

Launched as Unique Mobility Inc. in 1967, today UQM develops and manufactures propulsion systems for hybrid, plug-in hybrid, fully electric and fuel cell vehicles. The company has been around the block, seen a lot and done a lot, yet over the last five years, its simultaneous expansion into different product lines, new territories and new markets suggests a renewed vigor.

A diverse history

UQM has been involved in countless EV development projects – consumer, commercial and military vehicles – that go as far back as the ElecTrek electric car in 1979.

“Back at the beginning, UQM was an innovative company doing leading-edge engineering and R&D EV projects that allowed us to develop our deep understanding of motors and controllers, and that inspiration continues to this day,” said CEO Eric Ridenour. “We then moved to doing projects for some big players: BMW, Caterpillar, the Department of Energy, the Department of Defense, Ecostar, General Motors and John Deere. Our strategy then shifted to volume production, building a new production facility and headquarters, installing significant capacity and meeting all of the requirements necessary to be a Tier One supplier. Even with our move into volume production, we always stay true to our spirit of innovation.”

The 1980s and 90s brought many firsts for UQM, as it worked on the BMW E1 fleet of electric vehicles for California, the first electric camera truck used in the Olympics, and prototype hybrid HMMVs for the military. In 1998 UQM worked with Lee Iacocca and his EV Global Motors. It built the powertrain for the GM Precept Hybrid that was shown at the 2000 North American Auto Show. In 2008, a UQM motor propelled the first manned flight of a fuel cell-powered plane made by Boeing. Audi showed off the A1 e-tron concept car in 2010, featuring a UQM motor. The following year, Rolls-Royce debuted the 102EX Electric Phantom, with a UQM PowerPhase propulsion system.

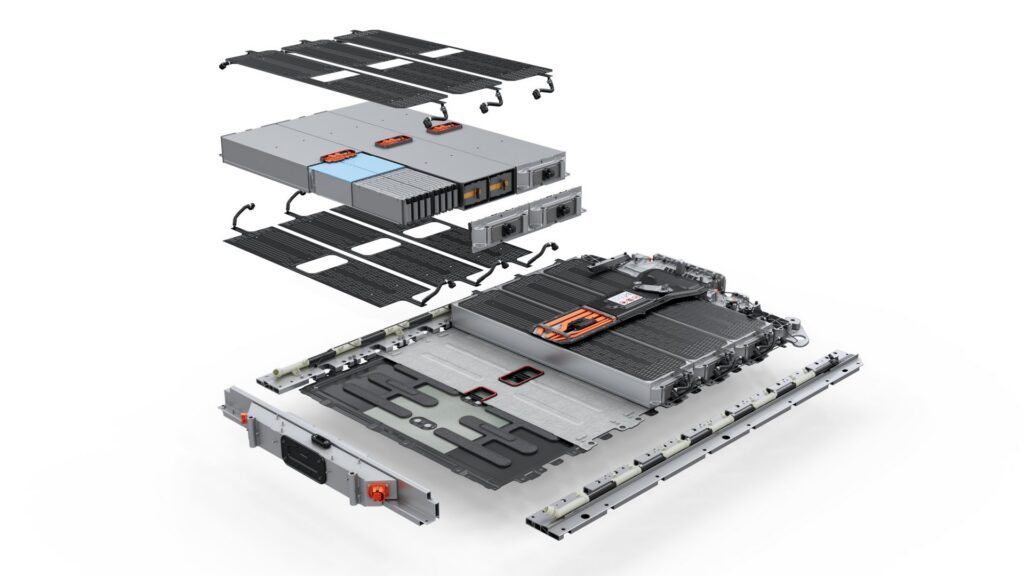

UQM officially launched production of the PowerPhase Pro in 2011 for an automotive customer, setting the baseline for what UQM is now best known for: developing and manufacturing compact, high efficiency motor and controller systems. The company told us that its long and diverse history has led to customer-focused products, with features like user-selectable torque and speed, and a motor, controller and software combination that’s optimized to work together in the most power-dense and efficient way for any given application.

In the last few years, the company’s large-application propulsion systems have found their way into yachts; speedboats; military applications like robotic vehicles, Humvees and armored vehicles; sports cars; trains; and fleet vehicles like shuttles, buses and trucks from companies such as EVI, Proterra, Hino and others. Earlier this year, UQM supplied the electric motor and controller used in the Acciona electric rally car, the first zero-emission electric car to compete in the Dakar Rally, considered by many to be the most rigorous race on the planet. This latest addition to the UQM power sports resume adds to the previous feats of EV pioneer and famous risk-taker Chip Yates, who used UQM products in his record-setting electric motorcycles and electric-powered airplanes. When asked about UQM, Chip Yates didn’t hesitate. “UQM has helped me achieve 18 world records and do things people never thought were possible. For that I’m eternally grateful.”

Proudly certified

As the EV market ramped up over the last few years, UQM kept pace by seeking out ISO/TS 16949 certification and achieving it in March 2014. That certification is considered to be the highest automotive quality standard, and it lent a world-class cachet to UQM’s 130,000-square-foot Colorado manufacturing plant, which has a capacity for high-volume production.

UQM’s choice to pursue full TS certification was prompted by a development project with a major OEM. UQM then doubled down, completing the remaining OEM Tier One requirement of ISO 14001 environmental certification, which was announced in February 2015. This certifies that UQM upholds the highest environmental quality standards, and that it has a system in place for continuous improvement of its environmental impact.

The company then set out to bring its OEM-level quality and production capacity to important emerging EV markets. The Asian truck and bus market has shown particular promise. From the one-ton truck market in Korea to heavy-duty vehicles and buses in China, these eastern opportunities have provided a springboard for UQM to dive into the deep waters of Asian vehicle electrification.

Asian expansion

UQM issued a flurry of announcements early this year concerning its new dealings in Asia.

In February, the company’s PowerPhase HD 250 received Chinese General Specifications certification from the China Automotive Technology & Research Center in Tianjin. Ridenour said that this addition to UQM’s certification collection “was essential to doing business in China, and the achievement helps us move closer to volume system sales in that key market.”

Just two days after its Chinese certification, UQM announced a 10-year production and supply agreement with Changzhou’s Keshi Group, a major manufacturer in the Chinese mining industry. Under the agreement, UQM will supply core parts for an explosion-proof propulsion system, while Keshi will source additional components and handle the final assembly. Ridenour said the two companies worked together for almost a year designing the explosion-proof propulsion system. Production will begin this year and then ramp up over several years.

The company also entered into a business relationship with the South Korean EV manufacturer Power Plaza to provide its PowerPhase Pro 100 system for converting one-ton diesel trucks to electric. Each PowerPhase Pro 100, which has 300 Nm of peak torque and 100 kW of peak power, is made up of a liquid-cooled permanent magnet motor and a liquid-cooled inverter with a digital signal processor chip. Power Plaza is one member of a consortium of companies that’s working directly with the city government of Seoul to use clean energy vehicles in their various municipal fleets.

The PowerPhase Pro 100 is the light-duty end of UQM’s product line. The PowerPhase HD 250 occupies the heavy-duty side, with 900 Nm of peak torque, 250 kW of peak power, and up to 95% efficiency.

Additional growth areas – energy management, fuel cells and marine markets

UQM’s business expansion doesn’t end with reaching new territories. The company recently signed a long-term supply agreement to provide electric power systems for industrial and commercial applications to an energy management company that does not yet wish to be publicly identified. UQM’s electric motors and controllers will be incorporated with this company’s proprietary technology to create new energy management solutions to address the needs of a wide range of global customers.

“We see this announcement as a significant milestone for UQM,” said Ridenour. “The addition of a new high-volume segment with different market drivers and end customers expands our targeted addressable market beyond vehicles. The proven high efficiency, high power output and robust design of our systems makes them ideally suited to energy management solutions such as this.”

In February, UQM acquired the fuel cell compressor module business of Roush Performance Products. Previously, UQM had supplied components for this compressor. Beginning in May, UQM took over manufacturing the full line of fuel cell compressors. Ridenour explained that UQM’s new fuel cell compressors would increase the company’s gross profits and provide opportunities to expand the business further. That prediction quickly played out when the company took its first fuel cell compressor purchase order in early March from Ballard Power Systems, a manufacturer of proton-exchange membrane fuel cell technology. UQM expects to continue a strong relationship with Ballard and build on the momentum of this first sale. Ballard’s COO, Paul Cass, said he expected to work with UQM “on a variety of fuel cell products.”

The company is on the kind of roll in a high-growth industry that attracts attention it never sought. In the last few years, UQM has moved into so many niche markets that it’s hard to summarize them all. For example, UQM is growing in the marine space. At the Miami International Boat Show in February, UQM’s marine integrator was advertising a payback period of 18 months for diesel replacement in fleets of ferries and patrol boats, and less than 12 months for gas engine replacement in commercial operation. According to UQM customer Pierre Caouette, a specialist in the marine electric propulsion industry, “The automotive-certified line of products manufactured by UQM is far above the competition in terms of volume, weight and efficiency, thus making them ideal for the difficult marine environment. It is great to have the UQM system and to be able to show that we have what it takes to efficiently electrify the marine world.”

The next steps

Consumer EVs from the high-profile automakers tend to get all the press, but the growth potential for electrified systems spreads to every corner of transportation. Beyond the operational cost savings, government policies around the world are getting more aggressive with fuel economy standards and emissions reductions, and every type of vehicle builder on the planet is looking towards electrification for compliance. For UQM’s diversified application approach, the result is a mountain of new opportunity.

UQM has positioned itself as a technology leader, with the capability to produce high-quality products in volume. Ultimately, the company knows its growth will be fueled by continuing to grow with its current customers, winning significant volume contracts, and providing new products that not only meet, but exceed customer expectations. “We continue an aggressive business development process and look for unique markets and new applications. We’re fielding projects and inquiries all the time,” said Adrian Schaffer, VP of Sales and Business Development. “We think that with the discussions underway in China, the new markets we have entered will fuel our revenue growth in the coming years to allow us to reach our goal of profitability and carry us strongly into the next wave of the electrification movement.”

This article originally appeared in Charged Issue 19 – May/June 2015.