We write about electric buses a lot at Charged. That’s because, as our July/August cover story pointed out, we think that e-buses will inevitably become the top choice for cities and municipalities. This could happen a lot quicker than many people realize, and some have predicted that transit buses will be the first segment in transportation to make the transition to all-electric.

Topping the list of reasons to switch to electric buses is cost – they’re a lot cheaper to own and operate. Replacing a diesel bus with an EV can save hundreds of thousands of dollars per bus over its lifespan. They’re also much quieter and cleaner. Furthermore, many local, state and federal governments around the world are beginning to lay out plans that mandate a complete transition to electric transit buses.

As a result, the electric bus industry is evolving quickly, and a pack of leaders is beginning to take shape.

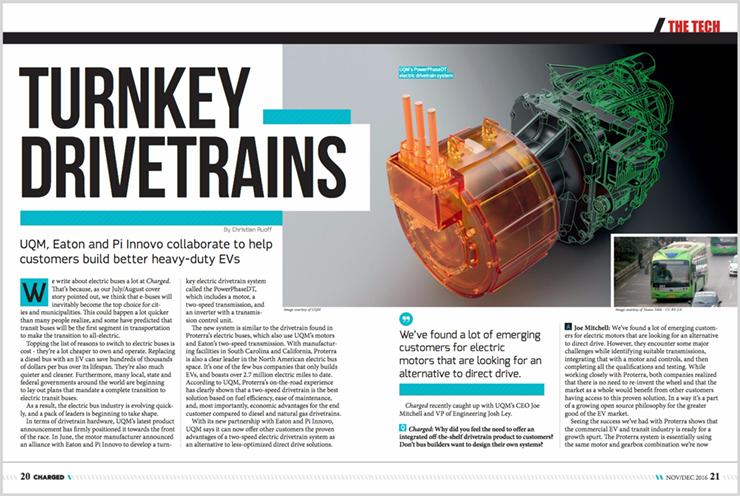

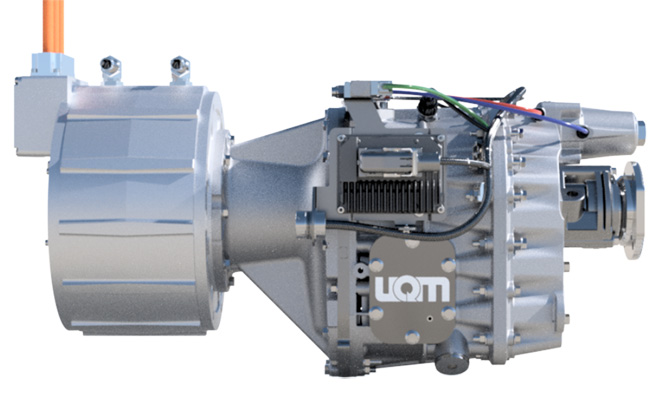

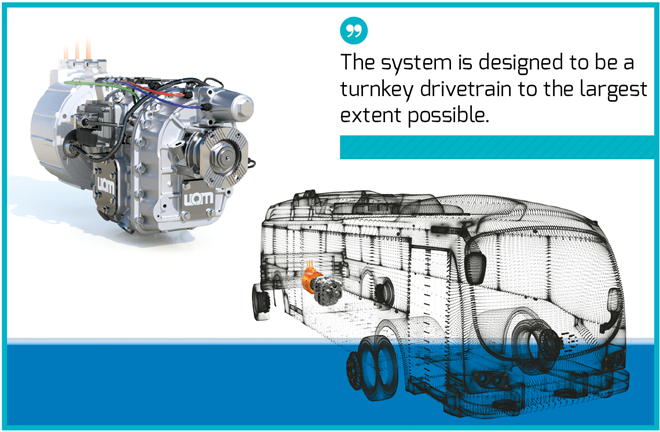

In terms of drivetrain hardware, UQM’s latest product announcement has firmly positioned it towards the front of the race. In June, the motor manufacturer announced an alliance with Eaton and Pi Innovo to develop a turnkey electric drivetrain system called the PowerPhaseDT, which includes a motor, a two-speed transmission, and an inverter with a transmission control unit.

The new system is similar to the drivetrain found in Proterra’s electric buses, which also use UQM’s motors and Eaton’s two-speed transmission. With manufacturing facilities in South Carolina and California, Proterra is also a clear leader in the North American electric bus space. It’s one of the few bus companies that only builds EVs, and boasts over 2.7 million electric miles to date. According to UQM, Proterra’s on-the-road experience has clearly shown that a two-speed drivetrain is the best solution based on fuel efficiency, ease of maintenance, and, most importantly, economic advantages for the end customer compared to diesel and natural gas drivetrains.

With its new partnership with Eaton and Pi Innovo, UQM says it can now offer other customers the proven advantages of a two-speed electric drivetrain system as an alternative to less-optimized direct drive solutions.

Charged recently caught up with UQM’s CEO Joe Mitchell and VP of Engineering Josh Ley.

Charged: Why did you feel the need to offer an integrated off-the-shelf drivetrain product to customers? Don’t bus builders want to design their own systems?

Joe Mitchell: We’ve found a lot of emerging customers for electric motors that are looking for an alternative to direct drive. However, they encounter some major challenges while identifying suitable transmissions, integrating that with a motor and controls, and then completing all the qualifications and testing. While working closely with Proterra, both companies realized that there is no need to re-invent the wheel and that the market as a whole would benefit from other customers having access to this proven solution. In a way it’s a part of a growing open source philosophy for the greater good of the EV market.

Seeing the success we’ve had with Proterra shows that the commercial EV and transit industry is ready for a growth spurt. The Proterra system is essentially using the same motor and gearbox combination we’re now offering in the PowerPhaseDT system – and we determined it was very strategically important for us to provide the entire package to customers, so they can avoid some of the pitfalls we’ve seen in starting from scratch.

Proterra is one of the few companies that has designed electric buses from the ground up. Its engineering team has invested a lot of resources to find the best possible solutions – from the two-speed drivetrain to lightweight designs and innovative charging. All of this has given them a leg up in the market.

So from a volume perspective, we’re able to build upon that work, combine costs and spread it over many more units to offer best pricing to many different customers with a turnkey solution. This was also discussed at length with Proterra and will benefit them as UQM establishes a wider customer base.

We also have a knowledge advantage. We’ve been able to look closely at everything out there, and select the best transmission option. Even if vehicle manufacturers and vehicle integrators had the ability and time to do that, it would require a lot of investment dollars on their end. The truth is that most don’t have the resources to do the comprehensive engineering effort required to select a transmission and do the qualification and control strategy.

So, the easiest solution for many customers is to just go with direct drive, even though they know that a two-speed option could offer some distinct advantages. With this new off-the-shelf solution, all that hard work is done.

Josh Ley: On the technical side, implementing an electric drive system is different than a traditional diesel, which most bus builders are familiar with. The transmissions for applications in the diesel realm are usually big and very heavy 9- or 10-speed transmissions. You don’t need all those gears and you save a lot mass with an electric motor and smaller transmission. For battery electric applications you only need somewhere in the range of two or three speeds.

So, it’s very important to find the right gearbox with the correct input torque and input speed, and that is somewhat scarce for the input conditions needed with advanced electric machines. The solutions are out there, but somewhat rare. With the PowerPhaseDT, we’ve already done the analysis to bring the best applicable components to the table.

Charged: Can you describe the main advantages that would lead customers to choose a two-speed transmission over direct drive?

Josh Ley: There are three distinct advantages of using a two-speed transmission: efficiency, weight and cost. Electric motors are essentially sized by torque requirements, because the physical size and torque are related. The higher the torque requirement, the larger a machine is needed. Gear reduction exists to reduce the speed while multiplying the torque. So the torque required from a direct drive motor is significantly more than what is needed if you use a motor and transmission.

When you reduce the motor mass, there is also a cost reduction. Even with the addition of a transmission, there is usually an overall savings in weight and cost, because the internal commodity-based components of a motor are more expensive than the materials within a transmission. The motor contains copper, electrical steel and powerful magnets. When you reduce the weight of the motor by three or four times, the overall system cost comes down, and a transmission does not increase the weight three or four times, so it’s a net advantage.

In terms of efficiency, the two-speed transmission helps in a similar way to an ICE. The main goal of the transmission with an engine is to keep within the power band. With an electric machine, the goal of a transmission is keep it in the high-efficiency band for a larger part of the drive cycle. So shift strategy is intelligent to keep the motor operating in its most efficient region at any given time. This is where the UQM software experience excels, because we always talk about a system, and that leads to total system efficiency over 95%. In a sense, we have added the other key component to what is now a comprehensive propulsion system.

Charged: What were the biggest engineering challenges that you had to overcome when developing the PowerPhaseDT drivetrain?

Josh Ley: Basically, the development effort was on the control side and developing the software to optimize the shift strategy. For this effort, we sought to maximize both efficiency and also smooth operation and drivability through the shift cycle.

Joe Mitchell: One of the big advantages of this powertrain is that mechanically it’s already been proven in the field with the Proterra application. They’ve had millions of miles of road time on this powertrain hardware.

Proterra designed a custom controller for their application, and we developed a generic controller that can be set up to run with many different customers. We worked with Pi Innovo to develop that stand-alone transmission control unit.

Charged: What sort of integration or calibrating will a customer have to do when they design an electric bus with PowerPhaseDT?

Josh Ley: The system is designed to be a turnkey drivetrain to the largest extent possible. There is some software calibration that has to be done in the field, as with all vehicles. In this case it’s mostly to be sure that the shifting is occurring at the right points. So the customer simply creates the wiring harness on their side that connects to our system, and then does some minor fine-tuning. The time to market is reduced drastically. Get to market faster, generate revenue faster. This will drive cost down in the supply chain and help everyone in the EV market.

Charged: Are you looking at other commercial vehicles or market segments that would work well with this new drivetrain?

Josh Ley: The system could drive larger vehicles as well, depending on the top speed and the weight limit. In fact, many of those larger vehicles already have limits on speed for other reasons, so there are a lot of possibilities. Our HD lineup has been used in many heavy-duty vehicles in on-road and off-road applications, so the durability, testing and validation is in place for a variety of commercial vehicle types.

This drivetrain uses our motor/inverter combinations from our PowerPhase HD family of products. Currently we have three variations of that product that range between 140 and 250 kW, with peak torque between 700 Nm and 950 Nm out of the motor itself, and obviously the transmission multiplies that output. The PowerPhase HD family operates two different voltage ranges: one range that centers around 360 V nominal and a higher range that centers around 600 V nominal. We’re also a pretty flexible company, and have the ability to quickly turn a prototype of any custom specification that we receive. We also have a lot of semicustom options and flexibility to tailor existing designs to an application quickly and benefit from a reduced validation timeframe.

Regarding the initial customers, our first step is to work with our pilot partners in key markets on the 10- to 12-meter transit and commercial bus market around 18,000 kg, which is the 40-foot buses here in the US. That size is the sweet spot for this transmission. We seem to be fielding calls daily from major bus manufacturers interested in the start of drivetrain production.

Joe Mitchell: The PowerPhaseDT is also totally agnostic about the power source that drives it. You can design it around many different types of battery packs, fuel cells or range-extended hybrid systems. All the end customer needs to do is choose the central vehicle control system, accessories, charging system and energy source, and the puzzle is complete.

Charged: What stage of commercialization are you at with the PowerPhaseDT? Are you currently delivering to customers?

Joe Mitchell: We’ve announced that full production will begin in 2017. Right now we’re in the testing stage with hand-picked pilot partners. These are customers that we identified with the ability to take the PowerPhaseDT to volume that were interested in working with us on the development. We are also in ongoing discussions with interested parties that either wanted to be part of this first wave but the timing didn’t work out, or want to get prepared for when production starts in 2017. Honestly, we’ve had more interest in this product offering than we expected.

We currently have three pilot partners in Asia (Hybrid Kinetic Group in Hong Kong, Wuzhoulong Motors and Yangtse Bus through ITL in China) and one in North America (ADOMANI), and we’re in the final stages of identifying a European partner.

Charged: China is clearly the largest market for electric buses at the moment. Do you expect to see a lot of high-volume orders for PowerPhaseDT from China?

Joe Mitchell: Yes, definitely. The orders coming from China for electric buses are orders of magnitude larger than anywhere else – you can add zeros to the end in terms of volume. There are some great things going in North America and Europe too, but from a volume and commercial viability standpoint, the biggest things are happening in China.

That’s why it was very important for us, strategically, to find the best approach for entering that market. It’s very difficult for a small foreign company to go in and truly be a player in China. So a few years ago we began a process to identify the best potential partner. We had a list of over 50 companies at one point and, over time, narrowed that list down until it was clear that Hybrid Kinetic Group (HKG) was the best option. In June we announced a new partnership with HKG that will bring us an infusion of new capital and the ability to install the infrastructure to support the market in China. Also, very importantly, HKG will bring us access to the Chinese market that would be very difficult for us to accomplish on our own.

They have great capitalization, an ability to invest in UQM, and many contacts in the market that will open the doors for us. HKG primarily develops and manufactures batteries and battery management systems, and will manufacture electric and hybrid vehicles. So it ended up being an excellent partnership that gave us the ability to present ourselves in China with some domestic ownership.

They already have the captive market and great customers, and will also give us the autonomy to be able to expand into other markets beyond just HKG. There is a lot of potential there. China has over 40 bus OEMs, and everyone is looking closely at electric drive.

So overall, this is all consistent with the strategic process that was outlined several years ago. Identify the potential growth markets, address the technology gaps with viable solutions, and identify partners that will provide us with the capital to expand our global reach.

This article originally appeared in Charged Issue 28 – November/December 2016. – Subscribe now.