The Switched Reluctance Motor, or SRM, is often discussed as a prime choice for the next-generation EV traction motor. It is simple, robust, and arguably the least expensive of all motor types to manufacture. However, SRMs are notoriously difficult to control, and prone to emitting significant amounts of vibration and acoustic noise.

The good news is that the disadvantages are not insurmountable. The demands of precise current control and accurate rotor position prediction are being met by computational-intensive control strategies and high-power microcontroller ICs. At the same time, much research is underway to tackle the vibration and acoustic noise problems.

Dr. Nir Vaks, co-founder and CTO at Continuous Solutions LLC, is one of those researchers. Dr. Vaks and his colleagues are working on a number of R&D projects, including an in-wheel-hub motor design, a high-efficiency gen set, and a novel approach to torque ripple mitigation (recently funded by a US Department of Defense grant). Minimization of torque ripple is important for motors in many applications, because it is one of the main causes of vibration that leads to premature wear on the drivetrain components and that pesky acoustic noise that plagues SRMs.

Charged recently caught up with Dr. Vaks to take a closer look at torque ripple in electric machines and his novel approach to active mitigation.

Charged: What exactly is torque ripple, and how does it differ in various types of electric motors?

Dr. Nir Vaks: Torque ripple is created by harmonics in the electromagnetic torque, which exist in all electric machines regardless of type or design. The harmonics are created by non-idealities in the electromagnetic fields produced by the rotor and stator interaction.

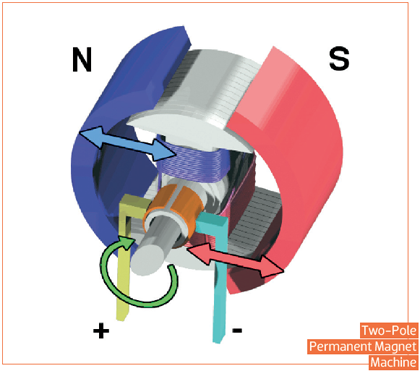

It is an issue with all motors, but there are differences. For example, if you take an induction machine and de-energize it – meaning you just have it sitting on the shelf – then grab the rotor and turn it, the only friction is the bearing friction and the momentum of the rotor’s mass. But with a permanent magnet machine, the magnets on the rotor are attracted to the steel on the stator. If you turn the rotor of a de-energized PM machine you will feel cogging, or an attraction between its stator tooth and the magnets.

So with a PM machine you have a torque ripple regardless of whether it’s energized or not. And often the ripple in PM machines is much more significant than in induction machines, DC machines, or wound-rotor synchronous machines (like alternators).

Charged: How do you measure and quantify torque ripple?

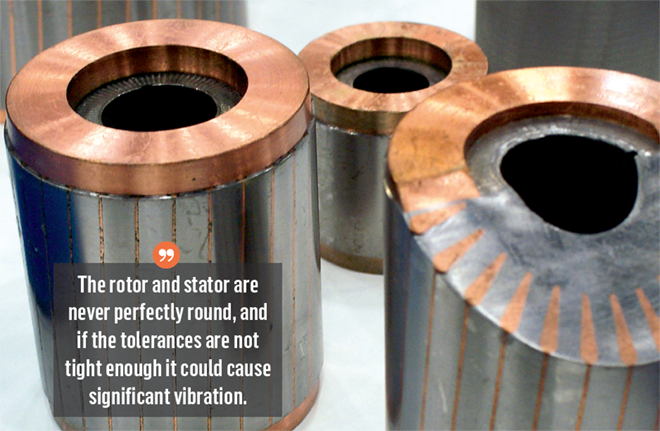

Dr. Nir Vaks: There are two sources of vibrations in motors. The first is mechanical – if the components are not fully balanced, if the air gap is not uniform, if the bearings aren’t equally lubricated. The rotor and stator are never perfectly round, and if the tolerances are not tight enough it could cause significant vibration.

But even if we assume near-perfect manufacturability – within one-thousandth of a millimeter accuracy – there is another source of vibration from the electromagnetic field, like the cogging torque or irregularities in the distribution of the electromagnetic field (which is never totally uniform).

To measure it, you kind of need to work in reverse. You take a motor and connect the shaft to a certain load with a torque sensor. Also attached is a sensor that can measure the vibration on the shaft. That will give you the vibrational profile of the machine, and then you can calculate the percentage of torque ripple compared to the average torque.

Say you have a motor with 100 Nm of torque that’s moving a vehicle forward. But on top of that 100 Nm direct quantity, you have this alternating output quantity, which is the torque ripple. So basically, you want the motor to rotate and move you forward, but it’s also moving slightly to the right, left, up and down. There is nothing beneficial in the torque ripple, it’s just vibration.

Charged: Is there a percentage of torque ripple that’s considered to be generally acceptable?

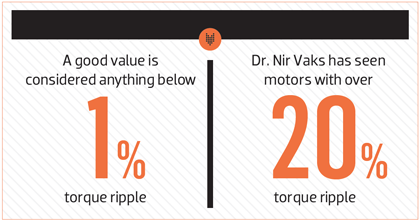

Dr. Nir Vaks: Anything below 1% is considered to be very good. So if you have a motor with 100 Nm of average torque, you would want the torque ripple to be ±1 Nm.

But it really depends on the application. If you look at some less-expensive PM machines, like the ones used in electric bicycles or scooters, you will see that the torque ripple is often very significant – I’ve seen motors with over 20% torque ripple.

And it gets really interesting when you look at the application dependence. If we’re looking at the vibration of the electric motor itself, that’s one thing. But once you put it underneath the hood of a car, then you get a different vibratory profile because there is all this other stuff that is connected around it. You can take a motor that has a 1% torque ripple and then connect to something, and those vibrations are amplified by other components.

Charged: So by the time a motor is used in a production vehicle from a major OEM, can we assume the torque ripple has been engineered down to under 1%?

Dr. Nir Vaks: No, not necessarily. It’s been a big issue for a lot of OEMs. The Japanese manufacturers, in general, have become very good at manufacturing PM machines, and they do it well. But if you look at motors made elsewhere, a lot of times that torque ripple quantity is much higher.

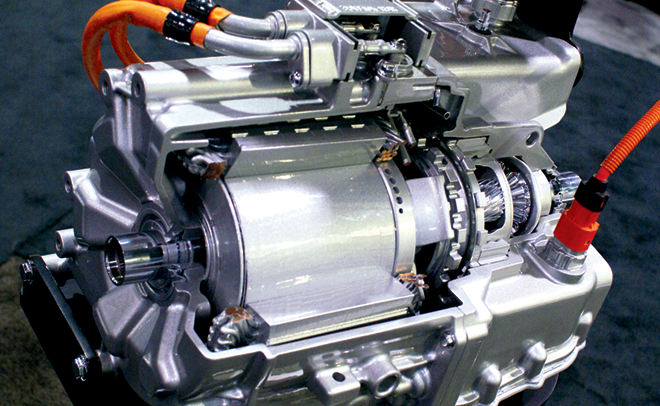

If you look under the hood of a typical hybrid vehicle, instead of putting millions of dollars into engineering a very low torque ripple motor, they build mechanics around it in such a way that it will mitigate those vibrations. Motors often sit on a very complicated vibration-mitigation plate – it’s basically a damping system to compensate for the torque ripple.

The systems are improving. If you compare a 2004 Toyota Prius and a 2014 Toyota Prius, you will see that the amount of suspension used for vibration-mitigation has been greatly reduced. That’s because they are designing less vibratory motors. Everyone is now trying to attack the problem at its source, which is the vibrations coming from the electric machine itself.

Charged: What techniques do engineers use to design a system with less torque ripple?

Dr. Nir Vaks: Torque ripple reduction methods can be broken into two categories: 1) modification of the physical geometry and design of the motor; and 2) mitigation via control of the current excitation waveform.

Physical modification of the motor has been shown to be effective at reducing torque ripple, however, it comes with financial costs and power trade-offs. The modifications may include things like redesigning the position of the permanent magnets or altering the stator teeth in a certain geometry so that the vibration being produced by the machine will be naturally below 1%. The problem is that these are very intricate changes that often require significant engineering time, materials that are a bit more expensive, and high-precision manufacturing. So as you’re reducing the torque ripple, the cost increases.

Not only that but, as you’re reducing the torque ripple, you’re also reducing your average torque. So, effectively, you get less bang for your buck. If you take a 100 kW machine with 10% torque ripple and make a lot of intricate changes to engineer it down to 1% (that’s if you’re good), then you now have around 85 to 92 kW overall power, because the changes also reduce overall torque. That’s definitely an issue.

So, we’re focusing on the second method – control-based torque ripple mitigation algorithms which are based on shaping the current waveforms.

Our approach, in concept, is similar to the active noise cancellation technology used in headphones. Those systems use a microphone to listen to the surrounding noise (which is vibration) and then takes exactly the same frequency to create a noise-cancelling wave that is 180° out of phase. We do the same thing. When the motor wants to jerk to the right, we control it in such a way that it also jerks to the left. In essence what happens is you get zero jerk – no vibration. In other words, the electronics adjusts the currents delivered to the motor so as to produce a torque ripple wave that is 180° out of phase when compared to the original “parasitic” torque ripple. Hence, cancellation of the parasitic torque is achieved.

It’s a tricky problem because you can’t just say, “give me torque.” It’s the current that produces the torque. So, you need to alter the three-phase current so that it will create a torque that will counteract the parasitic ripple.

Charged: What is novel about the control-based approach you’re developing at Continuous Solutions?

Dr. Nir Vaks: We’re developing a closed-loop torque ripple mitigation controller using a relatively inexpensive piezoelectric polymer for sensing torque ripple-induced vibrations. If you put voltage across a piezoelectric material it expands a little bit, but it’s also bidirectional, so you can press on it and a small voltage will be induced. We take this material and put it underneath, or beside, the motor mount. The vibration taps on the material to create a voltage profile that is proportional to this vibration. This allows us to measure the instantaneous torque ripple, and that vibration profile is fed into a computational device to change the three-phase excitation of the motor and create a vibration that is exactly the opposite. The system continuously adjusts until there is very little or no vibration.

One of the biggest advantages of this approach is that piezoelectric material is very inexpensive, so it could be a cost-effective solution deployed in all production vehicles.

Let’s say you have a motor that has a torque ripple profile of 5%. You don’t want to redesign it because it will cost a lot of money and it’s already integrated into your platform. All you would have to do is place the piezoelectric sensor somewhere near the motor and feed that signal into the controller that you already have. Then, in the power electronics control algorithm, you add another section of code to do the mitigation.

Of course, as you’re doing any kind of active control or current harmonics, there is a reduction in the machine output. So it will use a little bit more energy to do active cancellation, but the beauty of it is that it’s up to the user. Let’s say you are trying to pass a car on the highway and you put the pedal to the floor, you can program the controller to know that when this occurs you don’t care about vibration or audible noise for the next 3, 5 or 10 seconds. During that time the computer will know to disable the torque ripple mitigation and deliver the highest possible performance. Once you ease off the accelerator pedal, the computer can turn on the torque ripple mitigation again, which uses a little bit more available energy to cancel vibrations.

This is why the military and other high-performance applications are interested in this approach. A nuclear submarine, for example, is basically an electric vehicle. And the most popular way to detect the presence of a submarine is by its acoustic profile – you can listen for it with sensors. So if a submarine doesn’t want to be detected, with this sort of active control of the motor you can drive it in such a way that there is very little vibration. Then if you’re in a situation where you need full power, you can turn it off. That’s an extreme example, but it shows the advantages of active control.

Another advantage is that things change over time with all machines because of heat, wear and tear, etc. You can buy an off-the-shelf motor that has a torque ripple profile below 1%, but that doesn’t mean a year from now it will be that low. There is a good chance it will be higher because things deform and change. But with active control, the way you control the machine depends on the feedback. So, if the torque ripple goes up, it becomes more and more aggressive with the control method.

Charged: What are the next steps in the development of these closed-loop systems?

Dr. Nir Vaks: This research is a continuation of my PhD work at Purdue University, where I was able to prove the approach both in simulations and in hardware. I was able to mitigate over 99.8% of the torque ripple that is created in a permanent-magnet synchronous machine. It started at around 5% torque ripple, and the active control was able to mitigate it to around 0.05%.

The Department of Defense funding allows us develop the same approach for SRMs. Even though they don’t have permanent magnets, SRMs have a lot of vibration, which is why you don’t see them in high-performance applications like hybrids and EVs.

Right now we’re in the IP development stage. We’ve already proved the concept for PM machines and now we need to prove the concept in SRMs. Hopefully, a year from now we’ll be entering phase two with some serious hardware tests for the military, and then phase three is commercialization.

The biggest advantage for SRMs is that they are cheap, and the biggest problem is that they are cheap. Because of the low-cost manufacturing techniques, you get a lot of vibration. Again, you could mitigate the vibration through design, but then they wouldn’t be cheap anymore, or as powerful. SRMs are commercially available for some applications, but the vibration issue really limits their introduction into a lot of applications.

We want to proliferate this technology and make it commercialized. I definitely hope this will be another tool in the toolbox of fighting vibration and acoustic noise, and a very cost-effective one. So much so, I think it could really revolutionize the industry.

Read more EV Tech Explained articles.

This article originally appeared in Charged Issue 20 – July/August 2015. Subscribe now!