When EV manufacturers find a high-quality gap filler that maximizes battery performance, they don’t want to hit a snag with the application system.

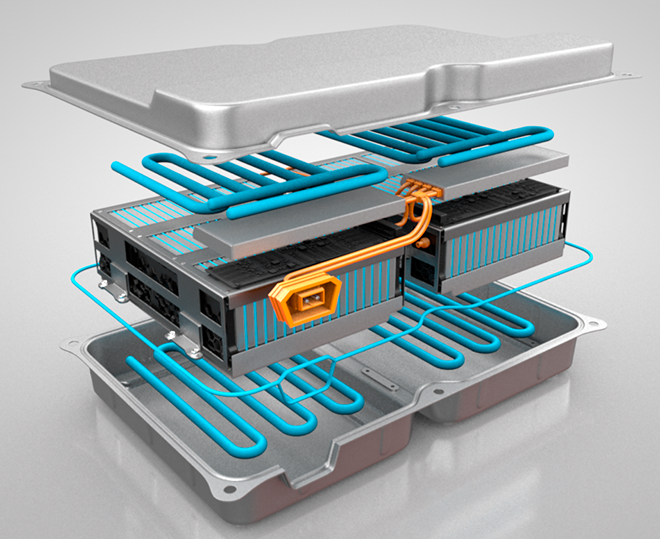

One of the fundamental challenges in designing an EV battery pack is the effective management of heat generated during the battery’s charge and discharge cycles.

A basic principle of physics is that heat can be transferred in three ways: radiation (the outward propagation of infrared waves), convection (the movement of molecules in liquids or gasses from hot areas to colder areas) and conduction (transfer of energy via direct contact with an adjoining body). Conduction is the most effective means of transferring heat, but currently, some leading car manufacturers use EV battery pack designs that employ radiant methods of heat dissipation. This can result in poor temperature distribution, hot spots and EVs that are limited in performance.

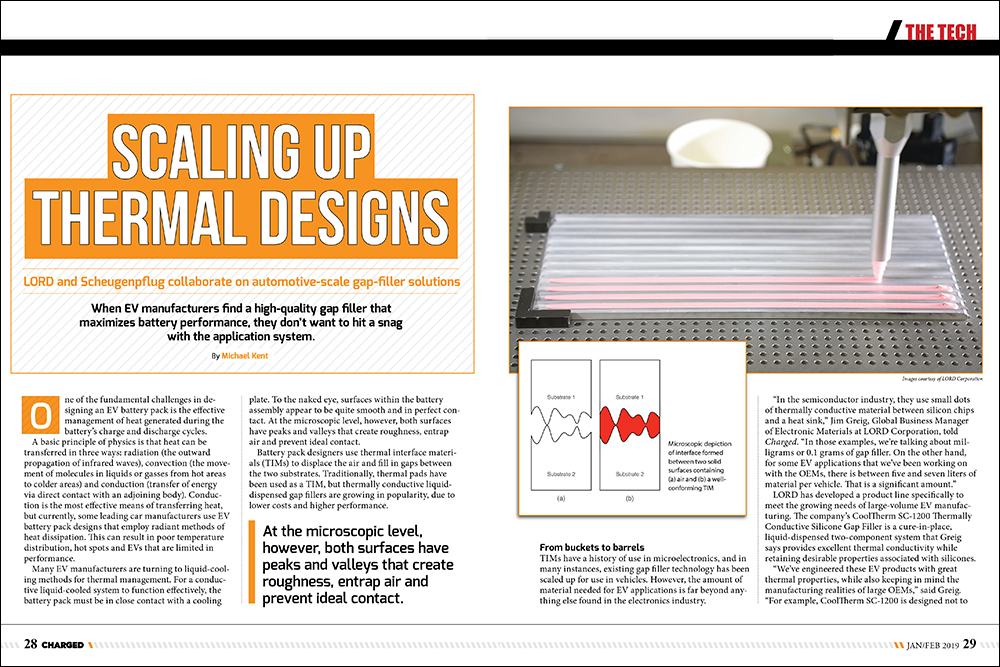

Many EV manufacturers are turning to liquid-cooling methods for thermal management. For a conductive liquid-cooled system to function effectively, the battery pack must be in close contact with a cooling plate. To the naked eye, surfaces within the battery assembly appear to be quite smooth and in perfect contact. At the microscopic level, however, both surfaces have peaks and valleys that create roughness, entrap air and prevent ideal contact.

Battery pack designers use thermal interface materials (TIMs) to displace the air and fill in gaps between the two substrates. Traditionally, thermal pads have been used as a TIM, but thermally conductive liquid-dispensed gap fillers are growing in popularity, due to lower costs and higher performance.

From buckets to barrels

TIMs have a history of use in microelectronics, and in many instances, existing gap filler technology has been scaled up for use in vehicles. However, the amount of material needed for EV applications is far beyond anything else found in the electronics industry.

“In the semiconductor industry, they use small dots of thermally conductive material between silicon chips and a heat sink,” Jim Greig, Global Business Manager of Electronic Materials at LORD Corporation, told Charged. “In those examples, we’re talking about milligrams or 0.1 grams of gap filler. On the other hand, for some EV applications that we’ve been working on with the OEMs, there is between five and seven liters of material per vehicle. That is a significant amount.”

LORD has developed a product line specifically to meet the growing needs of large-volume EV manufacturing. The company’s CoolTherm SC-1200 Thermally Conductive Silicone Gap Filler is a cure-in-place, liquid-dispensed two-component system that Greig says provides excellent thermal conductivity while retaining desirable properties associated with silicones.

“We’ve engineered these EV products with great thermal properties, while also keeping in mind the manufacturing realities of large OEMs,” said Greig. “For example, CoolTherm SC-1200 is designed not to be too abrasive. It’s also designed not to settle over time – meaning that the denser elements in the material won’t sink to the bottom during shipping and storage. This is very important to maintain the thermal performance and not clog the lines of the dispensing equipment.”

According to LORD, EV designers see the value of CoolTherm, and although he couldn’t talk specifics, Greig explained that the gap filler is advancing through design trials and winning new business from major OEMs all around the world.

Beyond creating a winning product, the scale of EV applications meant that LORD needed to think bigger about the equipment used in battery pack manufacturing.

Prior to application, CoolTherm SC-1200 resin must be mixed with hardener at a 1:1 ratio (by weight or volume). Automatic equipment is ideal for mixing and dispensing to avoid air entrapment in the material. Because SC-1200 is one of the newer materials on the market, and because of the sheer scale of EV applications, matching the product with a reliable dispensing system was a challenging priority.

The material is viscous and dense, and LORD said that some equipment that was tested with the product was unable to maintain proper mixing ratios, or experienced too much wear while dispensing the heavy material. There also were no dispensing systems appropriate for the high-volume production required by many EV battery manufacturers.

For electronics applications, gap fillers of this type are often supplied in 5-gallon buckets and limited to a weight that can be lifted manually by an average person. However, considering the large volume needs of an EV, a 5-gallon bucket could only hold enough material for three to six cars, so it became clear the only practical container is a 55-gallon barrel.

Material handling and dispensing

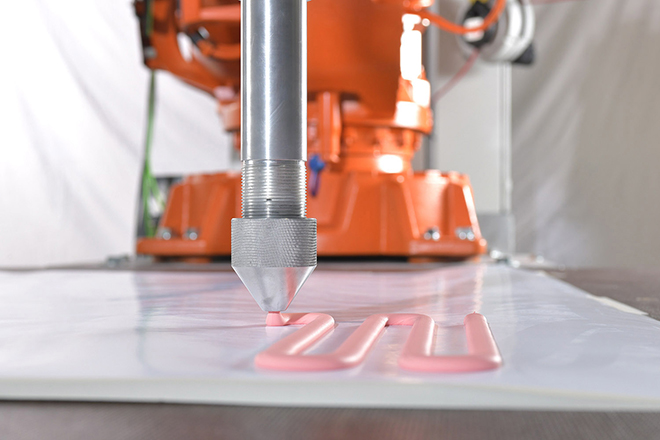

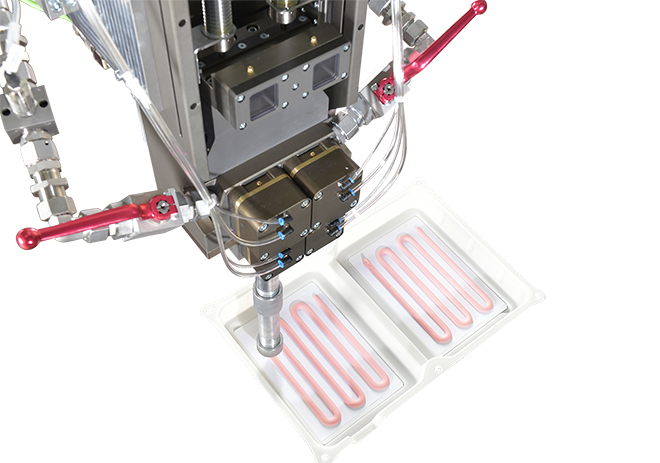

To meet the new market demand, LORD collaborated with Scheugenpflug USA on a high-volume dispensing system. Scheugenpflug is a worldwide provider of adhesive bonding, dispensing and potting equipment for the automotive market. The system created by Scheugenpflug uses 55-gallon drums, and is capable of dispensing high volumes.

At the outset of the product’s development, LORD and Scheugenpflug had more than a ten-year history of working together, and “Scheugenpflug had already provided proven systems that were capable of dispensing SC-1200 gap filler despite its weight and the fact that it is a dense material,” said Tim Vokes, an Applications Engineer at LORD.

In 2018, Scheugenpflug launched the new larger dispensing solution, which can apply potting material at rates of up to 80 ml per second with delivery pressures of 65 bar for highly viscous materials. These speeds are made possible by a combination of Scheugenpflug’s Dos HP dispenser and its PailFeed200 Abrasive material feeding unit.

“Working with LORD, we can now offer a tested and proven solution [for a problem] that has been a bottleneck for EV battery manufacturing,” Alexander Nguyen, Lead Sales Engineer at Scheugenpflug USA, told Charged. “Basically, we took our expertise in smaller-volume systems and supersized it. We’ve been perfecting this type of gap filler dispensing design for the last 15 to 20 years, and we have hundreds of the smaller-volume systems out in the market.”

The system can apply conducting media with viscosities of up to 1,000,000 mPa∙s, and has a maximum volume-per-shot of 310 ml. A 480 cm3 per stroke integrated double-piston pump makes continuous material feed possible. Scheugenpflug claims the system will offer a longer lifespan as well as cheaper, faster and simpler maintenance.

With a double-pump piston – as opposed to the more widely available high-pressure-driven systems – the system is responsive to the type of material. This is a critical consideration, given the fact that many materials have characteristics that can be negatively impacted by the dispensing process. “For example, some materials will begin to separate under high pressures,” explained Nguyen. “This can negatively affect the thermal performance if your dispensing system is not responsive.”

Scheugenpflug says that its volumetric metering head Dos HP combined with its PailFeed200 drum unloader makes the 55-gallon drum unloader the fastest high-accuracy dispensing system (for the volume) on the market.

“The system can greatly increase the current benchmarked production rates by handling highly viscous and dense materials, lowering the cost of material usage, and dispensing one liter of gap filler in 13 seconds,” said Nguyen.

In addition to Scheugenpflug’s proactive design process, the team incorporated field testing prior to product launch. Throughout the testing phase, CoolTherm SC-1200 resins and hardeners flowed well through the drum dispenser, with no issues in processing or material stability, according to Nguyen. “We officially launched the system in 2018 and it’s currently being used in production.”

“The Scheugenpflug team has been great to work with,” added Jim Greig. “They understand the challenges the EV industry is facing when it comes to dispensing high-viscosity filled materials, along with the customer’s desire to limit pail changeovers in high-volume production.”

For EV battery manufacturers, combining a high-performing gap filler with high-performing dispensing system offers streamlined operations, cutting time and cost.

This article appeared in Charged Issue 41 – January/February 2019 – Subscribe now.