It’s a common theme across the EV industry: Today many OEMs are designing their second- and third-generation EV platforms, and there is a strong push to increase packaging efficiency across the board, driving out every possible bit of cost.

In the past few months, we’ve written about GM’s decision to attach the power electronics directly in a cavity on the transmission of the new Volt – eliminating the orange three-phase cables completely by connecting to the motors through connection studs; Siemens’ new integrated motor and inverter drive unit – Sivetec MSA 3300 – which offers a plug-and-play option for OEMs; and the new high-force press-fit solderless interconnects by Interplex that significantly shorten current paths and overall inductance for inverter power modules.

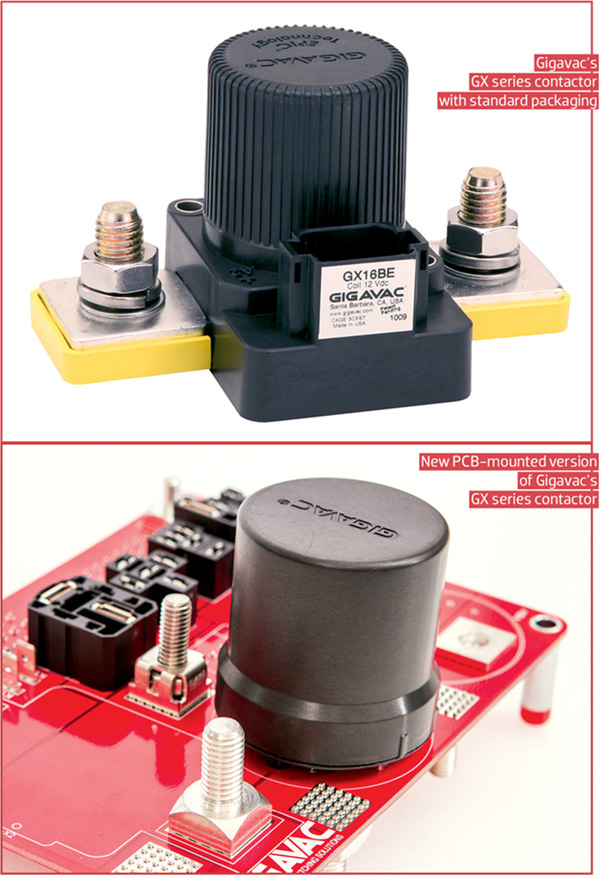

Not to be left out, Gigavac, the California-based sealed switching expert, has recently launched new versions of its popular contactors that are designed to integrate directly with printed circuit boards (PCBs).

Closing the circuit

Contactors, or electrically controlled switches, are similar to relays except that they carry much higher currents. Contactors switch an electrical power circuit on and off using a control circuit of much lower power than the switched circuit. They are used in many different applications (lighting, heating, capacitor banks, thermal evaporators, photovoltaic systems, etc) and range from having a breaking current of several amps to thousands of amps and from 24 V DC to many kilovolts.

In an EV system, the “main contactor” is used to make and break the power supply line running from the battery pack to the power electronics, isolating the high-voltage circuit whenever the vehicle is off.

The main contactor also has emergency interrupt capabilities and serves a critical safety role. In the event of an accident the contactor will disconnect the main batteries very quickly – similar to the speed of an airbag deployment. So, in automotive applications it’s important to use a robust contactor that can withstand vibration, the shock of an impact and the harsh environmental wear of the road.

EPIC advancements

Gigavac was launched in 2002 by a small group of founders with decades of experience in sealed switching products. Its first product line was a range of high-voltage relays, and in 2006 the company expanded into contactors based on its patented Extended Performance Impervious Ceramic (EPIC) sealing technology.

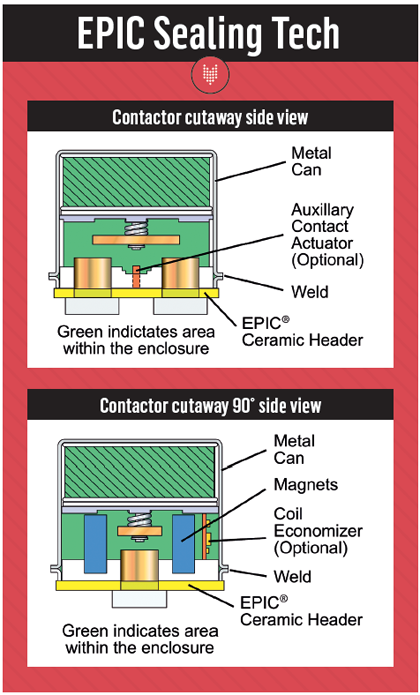

Gigavac says its EPIC technology is “a major breakthrough in low-cost, high-quality sealing of relays and contactors.” The company explains that other relay and contactor manufacturers use all-ceramic envelopes (which can be expensive), glass-to-metal seals (which can break down over long periods of time), or epoxy and plastic seals (which do not provide the high temperature ratings or the micro-sealing needed to use high-performance backfill gases). Gigavac, on the other hand, uses a unique ceramic-to-metal seal that it claims is “equal to or less than the cost of open-air or lesser quality epoxy and plastic semi-sealed contactors” and superior in quality, so it will work in almost any environment – even underwater.

Sealing is critical for contactors to prevent contaminants from polluting the internal parts of the compartment that contains the switching contacts. The EPIC ceramic-to-metal seal also allows you to fill the chamber with “virtually any gas” as a dielectric – which determines the precise control of the internal switch environment. The particular choice of dielectric is based on product design and the intended application. For example, Gigavac’s MX EPIC contactors use nitrogen as a dielectric, which allows for higher inrush and overload currents at lower voltages. For higher-voltage applications, GX EPIC contactors use hydrogen as a dielectric. The company also provides custom gas mixes for special applications.

Gigavac says this technology has been very successful since it was launched, and has fueled dramatic growth in what it calls its Power Products. “Our ceramic-to-metal seal gives us a lot of competitive advantages,” Jim Lanum, Gigavac’s VP of Business Development, told Charged.

“It has a very wide temperature range, and is incredibly durable and more compact because of the sealed chamber and controlled dielectric. We can do a lot more in terms of current and voltage in a smaller package.” Gigavac’s line of EPIC-enabled products now includes GX Industrial Contactors, MX High Reliability Contactors, and Sensing Contactors – all manufactured in the company’s 40,000-square-foot factory and headquarters outside of Santa Barbara.

Driving out costs

The exploding EV industry has been a clear boost to the company. Gigavac now supplies products for EVs of all shapes and sizes – from motorcycles and passenger cars to buses, trains and ships – and also to charging station manufacturers.

Working with one its highest-volume customers – an EV builder that the company declined to name – Gigavac has developed the stripped-down PCB version of its contactors, which it says offers significant cost savings. “Generally, it is at least 25% cheaper at high volumes,” said Markus Beck, VP of Power Products. “For that reason, we’re now seeing a lot of customers starting to board-mount contactors in the larger-volume automotive space.”

Contactors are bulky parts relative to most components mounted on PCBs, and they’re not cheap either – depending on current and voltage requirements, they can run more than $100 per part. While the individual part costs are lower for the PCB-mount version, Beck explains that the biggest savings are realized when you consider space and assembly saving. “From an ease-of-assembly point of view, it’s significantly simpler,” he says. “Instead of mounting the full switch somewhere and running busses or cables with connectors, this integrates into the BMS system or the high-voltage junction box of the vehicle.

“Then connections can be designed in many different ways, basically whatever type the customer wants, as long as it can carry the current. Some use the threaded connection in the contactor to sandwich to a board and buss, others insert pluggable contacts.”

Gigavac now offers PCB-mounted versions of its MiniTACTOR, GV, GX, and MX series contactors.

This article originally appeared in Charged Issue 22 – November/December 2015. Subscribe now.

![New York City may replace Central Park’s horse-drawn cabs with electric carriages [Updated]](https://chargedevs.com/wp-content/uploads/2025/09/AdobeStock_273233016.jpg)