When you see the name Pi Innovo, your first thought might be of the famous mathematical constant that begins with 3.14. If you read it too quickly, you might be reminded of Pinocchio, the delightful tale of a physically deformed puppet. But from now on, when you see Pi Innovo, here’s what you should think of: safe, simple and customizable Electronic Control Units (ECUs).

Pi Innovo began 27 years ago, evolving from a research project at Cambridge University to develop heavy-duty diesel engine control hardware and software. Today, the company produces custom embedded controllers for a variety of applications, including vehicle control units for EVs and hybrids. It has also developed electric parking brake controllers, Unmanned Aerial Vehicle (UAV) controllers for military applications, and a number of custom controllers for major OEMs.

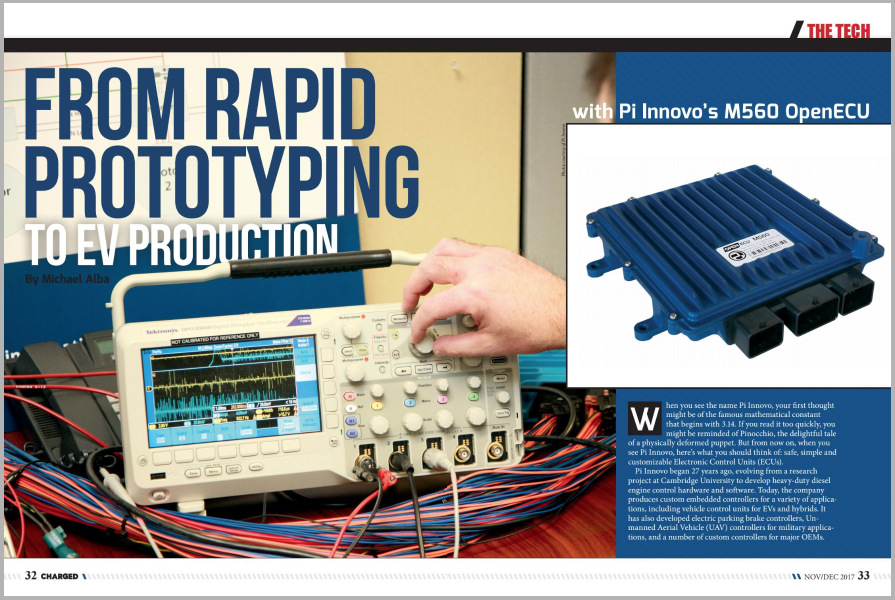

The M560 OpenECU

Pi Innovo’s newest ECU, the M560 OpenECU, is geared toward rapid prototyping and low-to-medium volume production of EVs and hybrids. The M560 supports supervisory control applications through a combination of ease of use, safety, and customizability.

“We’re trying to provide all the service, all the support, all the high-level engineering, the rigorous functional safety design,” explains Dwight Hansell, Vice President of Business Development, “for those customers who aren’t the really high-volume guys, but really need that level of service, support, quality and reliability in their ECUs.”

Contained in a rugged package, the M560 packs two powerful microprocessors, four Controller Area Network (CAN) 2.0 communication channels, 112 pins of flexible I/O, and integrated charging interface circuitry, among other features. One of the most appealing of these is the M560’s compatibility with MathWorks’ Simulink development environment.

“We provide an API for developing control applications that works through Simulink, so it’s a very industry-standard way of doing model-based development,” says Adrian Carnie, VP of New Business Development.

“We always make sure that our platform software is compatible with the latest MathWorks releases, so our customers can work with the latest industry-standard model-based design tools,” adds Senior Hardware Engineer Gordan Jurasek. The M560 also puts safety first, as it was developed in compliance with the ISO26262 safety standard. According to Jurasek, this is a time-saving shortcut that will go a long way to helping OEMs develop safe vehicles quickly. “Our product actually has that rigor built into it,” he says. “And we have the appropriate documentation and engineering support at the systems level to help engineering teams make new energy vehicles, and make them safe in a rigorous fashion.”

Specifically designed for the EV/hybrid market, the M560 is in various stages of development in a growing list of vehicles, including a PHEV, an EV, an electric bus, and a hybrid off-road recreational vehicle.

“They have a customizable, proven, automotive-level, fully-functional, safe ECU, and they don’t have to tool up anything to do it, they can just use it,” says Hansell. “We think there’s any number of people out there that are doing various electrification or hybrid programs that would need this type of unit. They won’t have to do a lot of development except whatever their application needs are.”

Custom ECUs and engineering support

Although the M560 OpenECU is an appealing option for many EV/hybrid supervisory control applications, sometimes you need a more tailored fit. One of Pi Innovo’s greatest assets is its capacity to customize – the company is more than willing to work with customers to develop an ECU to their exact specifications.

“A big portion of our business is pure custom ECUs,” explains Hansell. “So if a customer needs something custom, say they want a design to be cross-optimized for high volume, that’s a significant portion of our business. And we’re happy to support people doing those kinds of things as well.”

If you’re looking for an ECU that’s only slightly different than what’s on offer, Pi Innovo is also happy to help. Though the M560 was designed specifically for the EV/hybrid market segment, some customers may need slight tweaks to accommodate their specific requirements. No problem, says Hansell. “That’s one of the big advantages we have: to customize our hardware. So the customers don’t need to compromise their system, they can get exactly what they need. In fact, Gordan and I just got off a phone call with a European customer about a high-end luxury EV that they’re doing. They needed a few changes to accommodate some of their circuit needs. So Gordan worked with them, defined the exact changes they needed, and we are able to create specific custom variants of the M560 that will meet their exact needs.”

The support doesn’t stop at customization. For customers that want it, Pi Innovo will help fine-tune their systems and ensure their EVs are production-ready. “For the customers who desire that support, we can send a team of our engineers to help them go through all the final calibrations and make sure the vehicle is ready for production,” says Hansell. “Some customers have the confidence to do that themselves, so it depends on the customer. But we have the guys who can go and help the customer get it to the point where it’s ready for saleable vehicles to end customers.”

For customers who use the M560 for low-to-medium-volume production, and “hit the jackpot,” as Jurasek puts it – begin to sell more than they bargained for – there are no concerns with scaling up production to a different controller. Because the M560 doesn’t lock anything down into a proprietary system, these customers won’t have to redo any of their engineering efforts.

“If you actually hit the jackpot and you’re going to be selling tens of thousands, your software work, your calibration work, your control work, it’s not trapped in some proprietary system,” explains Jurasek. “It is fully industry-standard in terms of controls. So you can move it to whatever you want very quickly and easily, and you’re not trapped.”

“With OpenECU, you can grab a piece of hardware off the shelf and you can take your bright idea and get it working on your bench or in your garage or on your test track, in days or weeks,” says Jurasek. “We can get you up and running to demonstrate that your concept works.”

This article originally appeared in Charged Issue 34 – November/December 2017 – Subscribe now.