The commercial fleet market is one of the most exciting frontiers in the electromobility revolution, not only because of the enormous potential for fuel savings, but because it offers opportunities for a smaller company, which can hope to carve out a lucrative niche developing a powertrain solution, without the need to build the sort of massive manufacturing and marketing infrastructure that an OEM in the passenger car market needs.

Charged has covered several of the companies greedily eying this market. All of these firms are trying to find the “sweet spot,” but Echo Automotive (OTCQB: ECAU) has a unique proposition: it has developed a “bolt-on” solution that’s designed to offer fleet operators increased efficiency and lower operating costs with a minimum of installation hassle. Charged sat down with Echo Chairman Jason Plotke and talked about the company’s strategy.

Echo recently acquired the assets and intellectual property of Bright Automotive, and finished building a nationwide installation and service infrastructure that includes Meineke, Dickinson Fleet Services and Leggett & Platt. The company also finalized a supply agreement with motor builder Remy International, which includes the development of an induction motor system called the Echo Induction Machine, which Echo will assemble and distribute to other OEMs and integrators.

In early 2014, the company announced sales of EchoDrive to several customers, including a research institution and a municipality, which are now participating in the company’s beta program and will deploy EchoDrive production units later in the year. At current capacity, Echo could produce around ten thousand kits per year.

Through his experience with an earlier company, Plotke learned that, as he puts it, “Green is a tough sell if it doesn’t actually save money.” So Echo has made it a point to show fleet owners very clearly how electrification is going to save them money, and to minimize the risks (both actual and perceived) of making an equipment change. “We went down the list of what we call barriers or risks, from a commercial fleet perspective, and tried to mitigate them down to almost nil. What that left us was, how can we take an electrification product, and apply it to an existing vehicle [in such a way that] it allows you to use most of the same architecture, but creates tremendous efficiency in the process?”

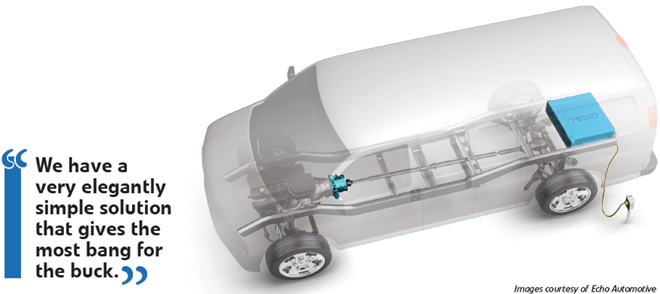

Echo’s solution doesn’t require the customer to buy a new vehicle, or even a new powertrain. It’s a plug-in hybrid modification to a standard drivetrain. “We have a very elegantly simple solution that gives the most bang for the buck,” says Plotke. “I can’t tell you I’ll give you the most efficiency, but I’ll tell you I can give you the best ROI – between three and four years, depending on the drive cycle and the load of the vehicle.”

The EchoDrive system consists of an induction motor, which is installed on the post side of the transmission, and a 9.4 kWh lithium-ion battery pack, which goes in the location of the spare tire carrier. No cutting or welding is necessary for installation. “We simply unbolt the cover, unbolt the driveshaft, slide our motor on, bolt it up where the existing cover was, and reinstall the original driveshaft back in the same location,” explains Plotke. “Our Level 1 and 2 charger, system controller, inverter and energy storage are all contained in that pack, so there’s not a number of installation points on the vehicle, there’s essentially just a couple. Now, we do have some harness connections, we plug in and listen to what the vehicle is doing and we augment our performance based on that. It’s really simple, and if that vehicle had to be put back to its original configuration, our products uninstall as easily as they install.”

EchoDrive employs both passive and non-passive regenerative braking. The system includes a regen lever that mounts underneath the steering column. “It’s similar to what Cadillac has just put out in their ELR model, although ours can modulate the level of braking, whereas in the Cadillac it’s on or off. It allows us to capture the maximum amount of regen possible. It also controls the brake lights. Like the Cadillac, it won’t take the vehicle to a complete stop, so it still needs the friction brake to actually stop the vehicle.”

Unlike many hybrid powertrains, EchoDrive does not run in fully electric mode, but rather provides assistance to the entire drive cycle. “For example, you hit the gas and, instead of the internal combustion engine doing all the work, we subsidize that energy load with about fifty percent of the load coming from our drive. The vehicle thinks it’s going downhill because there’s this alternate drivetrain system that’s propelling the vehicle in addition to the motor. We’re not able to operate the vehicle in EV mode, but we can run that power up to seventy miles an hour, and can even assist on the freeway, whereas others would flop from internal combustion over to electric or vice versa.”

Echo claims a fifty percent increase in miles per gallon. “We were just at the NTEA Show last week, where we had a ride-and-drive. We actually did a contest with a third-party fleet analytics company, to measure the performance of each one of these drivers and compare it against a baseline that they achieved with the vehicle without the system. The highest, with an untrained driver, was 58 percent, and the lowest was 42 with a little more training.”

EchoDrive is designed to be installed in four to six hours. “It’s not much more complicated than changing brakes, and it’s not as complicated as changing a transmission. So, there are a lot of fleets that actually put their own motors and transmissions in that would easily be able to handle this type of work. In case a fleet doesn’t have that ability, we’ve partnered with a number of service providers that have hundreds of outlets nationwide to facilitate not only the installation, but any potential service that would arise from that.”

Of course, different fleets use their vans in very different ways, and how much a particular fleet can save depends on its typical drive cycle. As part of its sales process, Echo will install a data recorder in a potential customer’s vehicle, record the drive cycle, and plug the data into a simulation, which generates a detailed estimate of the possible savings. “There are scenarios where, if you got out on the freeway in the morning and drove a hundred miles to a destination and turned around and came back, then our system would not provide very much value to you, because we need a lot of start and stop…We start with a high level of efficiency and we taper off as our pack depletes. After that, we still continue to operate as a hybrid, which gives us about a 20 to 22 percent increase in efficiency. So, even if you went outside your drive cycle for any given time, you would still have a significant amount of savings beyond just what the [plug-in advantage] could provide. We have awesome Level 2 charging, so, if the driver stops at Starbucks and uses what we call opportunistic charging, he can gain another 25 to 30 miles.”

EchoDrive records not only its own performance, but also the efficiency of the vehicle. “One of the things that we incorporated into the vehicle is a screen that mounts into the dash that provides feedback. Are they maximizing their regen? Are they accelerating too much? Are they idling too long? We help tailor their driving habits to drive more efficiently. All that information is contained in our system and we have the ability to report that back to the fleet in the evening or at the end of the week, so that the fleet operator or manager can take a report from his ten, fifty or a hundred drivers and say, ‘Hey, so-and-so performed very well this week.’ It’s almost become a game. We’re also able to report that the vehicle has a check engine light on or it’s up for service. So, there’s a lot of ancillary value that comes with our system.”

Echo’s products are 100 percent made in the USA. Corporate headquarters are in Scottsdale, Arizona and development and production facilities are in Anderson, Indiana, where the battery packs are assembled, using cells from an as-yet-undisclosed provider. The company also collaborated with Remy to develop a proprietary induction motor.

Echo aims to home in on the electrification sweet spot. Of course, so do a number of fleet-focused companies – like VIA Motors, XL Hybrids, Smith Electric, Motiv Power Systems, Boulder EVs, Wrightspeed and others – but no one else is doing exactly what Echo does. “[Some companies] get you a hundred miles per gallon, and can run you around in EV mode, but that comes at a high financial penalty. You’ve got to start with a brand new vehicle, which is going to be $30,000-$35,000, and then install a kit…that comes at a very high price.”

“[Others are using non-plug-in hybrids] that claim up to twenty-five percent efficiency, and they’re pretty expensive for that increase in efficiency, so their ROI is definitely longer than ours. I think that the plug-in offering at our price point gives you a lot more electric energy usage and offsets a lot more fuel consumption.”

Echo is shooting for a three- to four-year ROI period, and has done case studies that show how much money a fleet owner can save over the life of the vehicles. According to Plotke, the largest fleet owners such as FedEx, UPS and Coca-Cola are keeping their vehicles longer and longer. “Some of those companies are keeping those vehicles for ten, eleven, twelve years. One of the things that’s nice about EchoDrive is that you’re asking about fifty percent less of the engine and the brakes, so you can increase the life of that vehicle.”

Plotke estimates the savings on an average drive cycle at about $3,000 a year at current fuel prices. EchoDrive is designed to last for ten years. “If the fuel price stayed static, you’re looking at a $30,000 savings over the life of our kit. If fuel happens to go up in ten years, which I think all of us would believe to be the case, then you could see savings as high as $40,000-$45,000.”

There are a couple of other advantages to Echo’s unique bolt-on approach. “In the event of a collision in which the vehicle is totaled, or if the vehicle’s retired, our system can easily be unbolted and transferred to another vehicle,” says Plotke. EchoDrive also features what he calls graceful failure. “With any of our competitors, if their system were to fail, your vehicle becomes inoperable. If our system were to fail, we simply have an override switch where you turn it off and the vehicle continues to drive in its original configuration, because we haven’t modified anything in the existing drivetrain. You’ll lose efficiency until you get the system serviced, but that’s the least of your worries as opposed to having someone stranded. We’ve really done a lot to mitigate risks, and that’s a big one.”

This article originally appeared in Charged Issue 13 – APR 2014