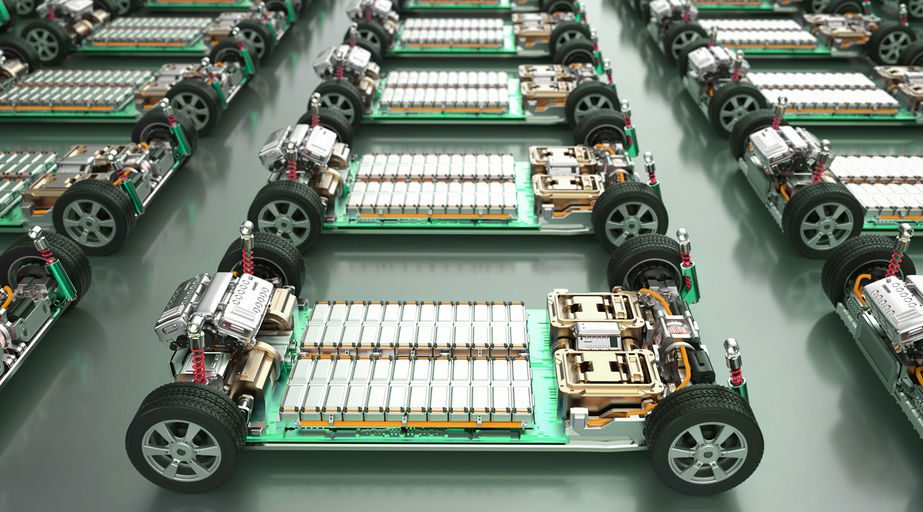

German chemical manufacturer BASF and US silicon battery materials manufacturer Group14 Technologies have collaborated on a market-ready silicon battery solution using commercially available materials: BASF’s Licity 2698 X F binder and Group14’s silicon battery material, SCC55.

BASF and Group14 claim they have developed a drop-in-ready solution that enhances the performance of batteries with silicon-dominant anodes, delivering faster charging, higher energy density and high extreme durability.

BASF’s Licity 2698 X F binder was developed specifically for silicon-rich anodes and can stabilize the electrode in the most demanding conditions. The collaboration optimizes BASF’s latest binder with the capabilities of SCC55, delivering robust cycle life and performance.

Under standard conditions at room temperature, test cells typically exceed 1,000 cycles with 80% of capacity remaining. However, at a temperature of 113° F, (45° C), these cells still achieved over 500 cycles while providing nearly four times the capacity of a traditional graphite anode, according to the companies.

“The future of energy storage powered by silicon batteries is here, and our collaboration with BASF is driving mainstream adoption at unprecedented speed,” said Rick Luebbe, CEO and Co-Founder of Group14 Technologies. “By combining technologies, we are giving battery manufacturers the power to deliver high-performance, scalable silicon batteries faster than ever to help meet today’s soaring energy needs.”

“Silicon is now an attractive technology without the limitations of the past,” said Dr. Dirk Wulff, Global Technical Battery Binder Manager at BASF. “By combining our expertise, we achieved an anode cell chemistry that not only meets but exceeds industry requirements.”

Source: Group14 Technologies