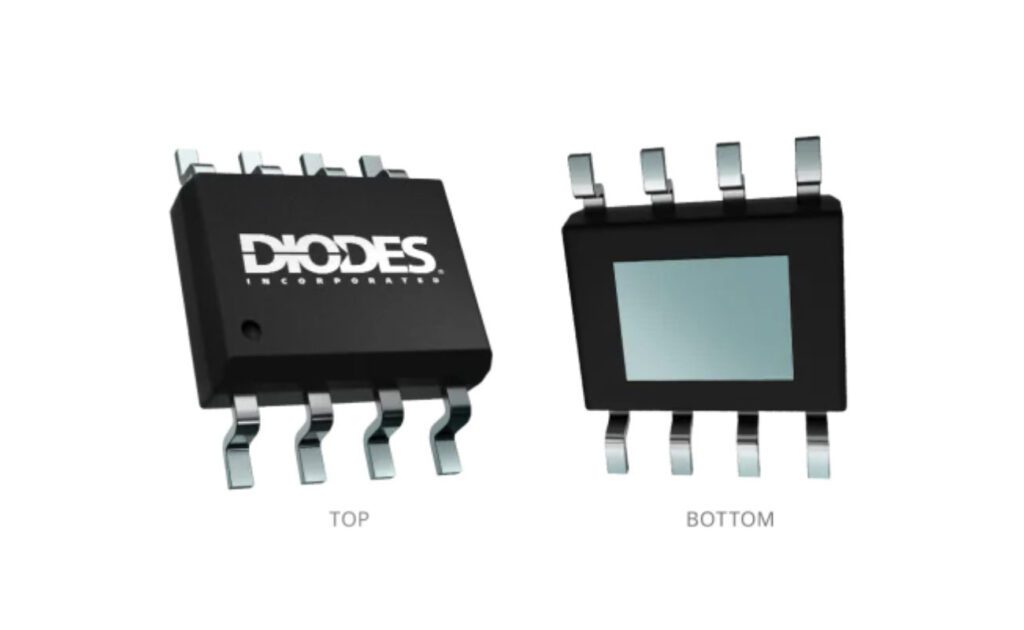

The electrification of the powertrain requires the massive use of power electronics and places new demands on the power semiconductor industry. For electromobility to become established, it must be cost-effective and reliable – to achieve this, power semiconductors must have a higher power density, increased efficiency and improved temperature resistance. This requires connecting materials to withstand higher power densities, switching frequencies and temperatures and meet higher reliability requirements.

Because of the increasing operation temperature, conventional aluminum wires will usually be a limiting factor for power applications in EVs. Compared to aluminum, copper has a better thermal and electrical conductivity and a lower coefficient of electrical expansion. However, bonding copper on the semiconductor is not possible as the semiconductor usually breaks while bonding due to the hardness of copper.

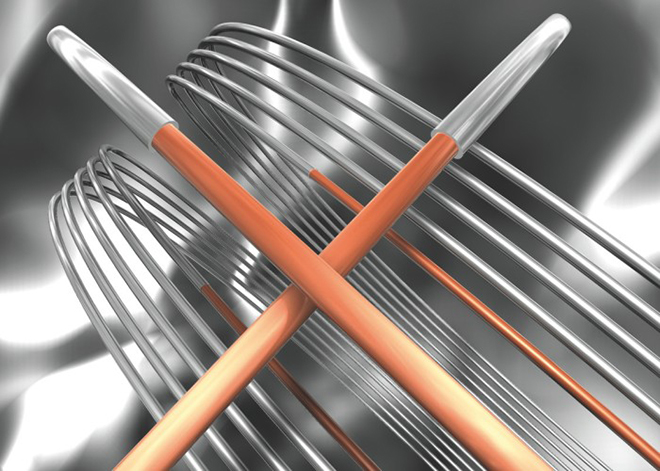

To combine the advantages of aluminum and copper within one wire, Heraeus has developed a new composite bonding wire named CucorAl Plus. The wire consists of a copper core and an aluminum shell and is simple to integrate into existing power module design.

By replacing aluminum wire with CucorAl Plus, manufacturers can extend module lifetime by a factor of five without changing the module design. This specifically caters to the e-mobility industry needing new materials and components that function in demanding environments. CucorAl Plus enables higher power density within the module design by fusing current capabilities and providing a 20 percent higher ampacity. The wire is designed for operation temperatures of up to 200 °C. It also has better mechanical properties compared to aluminum wire.

Heraeus not only provides high-quality materials, but also makes its process knowledge available to customers. In its power electronics application centers, the company helps manufacturers to improve their processes by jointly simulating them and developing prototypes.

Key benefits of CucorAl Plus:

- Enables power module operation temperature of up to 200 °C

- Up to 5x higher module lifetime compared to aluminum

- Enables higher power density within the module design, through 20% higher ampacity and fusing current capabilities

- Compatibility with standard bonding and standard chip technology

- Customer proofed