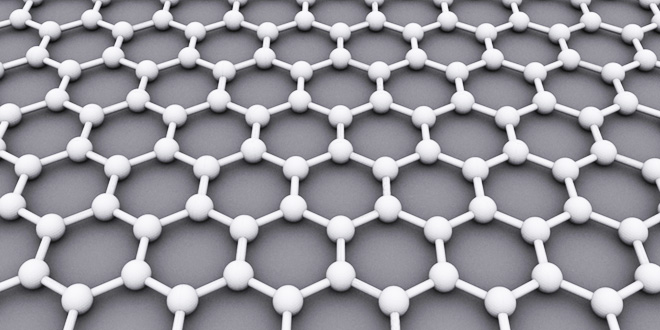

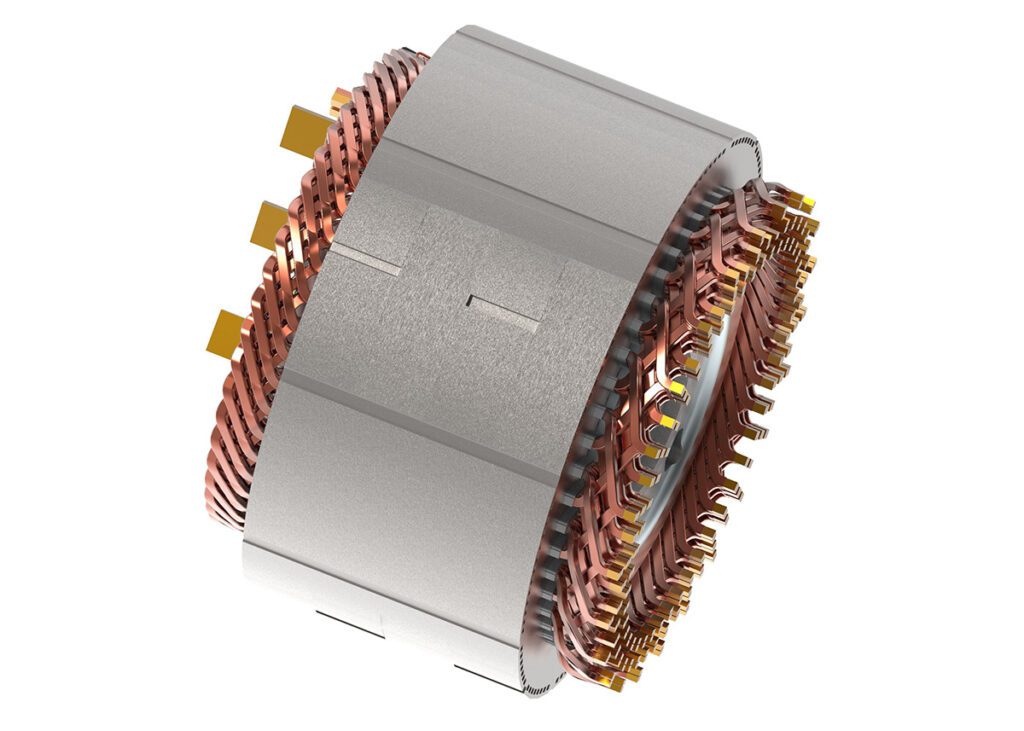

XG Sciences and Boston-Power have announced a joint development program aimed at customizing XG Sciences’ silicon-graphene anode materials for use in Boston-Power’s lithium-ion battery cell products.

The program will focus on optimizing electrochemical and microstructural electrode performance, as well as developing electrode and battery manufacturing techniques using the two companies’ proprietary materials.

MORE: Samsung invests in graphene manufacturer XG Sciences

“Silicon has very high storage capacity but has traditionally struggled to deliver the many charge cycles demanded in next-generation electronics and automotive applications,” said XG Sciences’ VP of Energy Markets, Rob Privette. “We see real synergy between Boston-Power’s battery engineering and design capabilities and our new XG-SiG anode materials. Boston-Power has the ability to design and manufacture the battery, while XG Sciences has the ability to customize our anode materials to best fit the Boston-Power system.”

“Given Boston-Power’s primary focus on electric vehicles, being able to squeeze more energy into the same physical space is certainly important for achieving longer drive distances,” said Boston-Power CTO Rick Chamberlain. “But higher energy density is an equally if not more important contributor to reducing the overall cost of electric vehicles, which will drive their adoption over the next 5 years. Our collaboration with XG Sciences is a valuable step in using silicon technology to achieve our product goals.”

SEE ALSO: Boston-Power introduces a modular system for assembling large-format battery packs

Source: XG Sciences

Image: AlexanderAlUS (CC BY-SA 3.0)