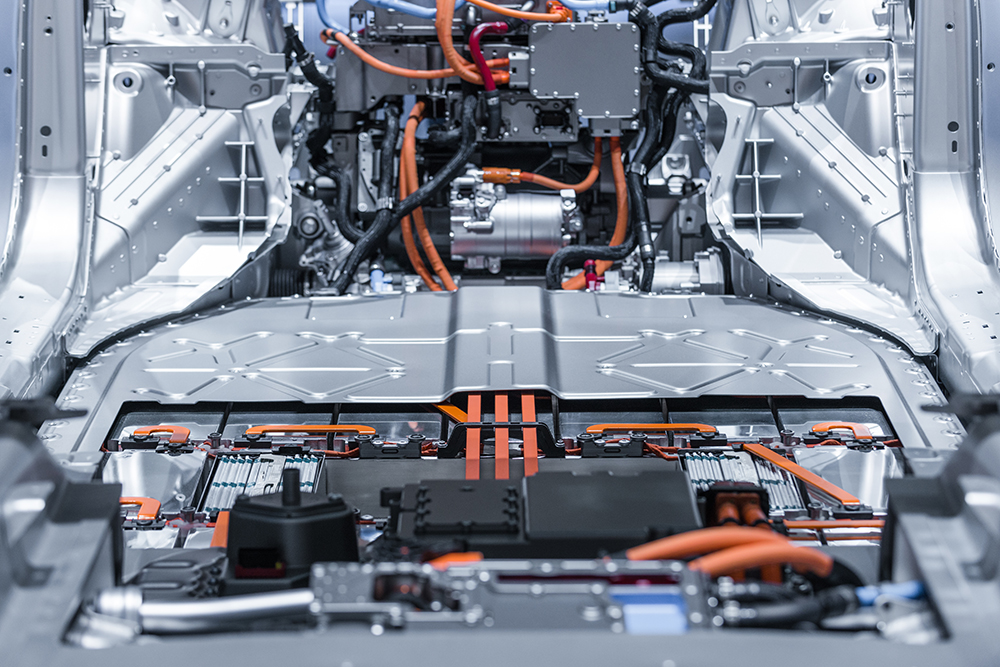

With the growth and development of battery pack technologies, manufacturers of electric vehicles (EV) place greater emphasis on pack design optimization, seeking more compact solutions to improve energy density and reduce cost. In the assembly of high-voltage battery packs, dielectric protection is critical. Manufacturers often apply dielectric materials to the battery cells, cooling plates, and adjacent components.

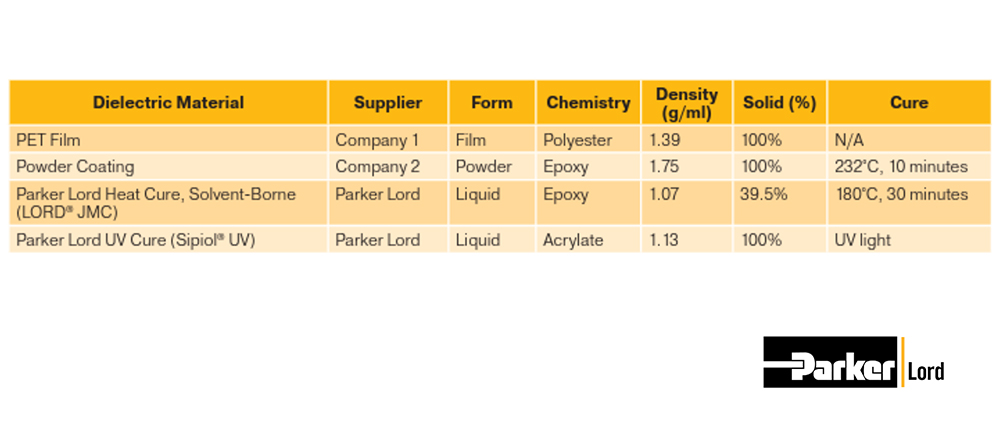

The team at Parker Lord developed a whitepaper “Assessing Technologies for Dielectric Protection of Battery System Components.” In this whitepaper, the team discussed their testing and comparisons of four different dielectric materials (Table 1):

- Polyethylene terephthalate (PET) film

- Powder coatings

- Solvent-borne coatings (LORD® JMC)

- UV-curable coatings (Sipiol® UV)

Dielectric materials are typically polymeric in nature and require the following performance attributes:

- High dielectric strength

- Good adhesion to substrates

- Durable after exposure to chemical, thermal, and mechanical forces

- Applied at thin film thickness (50-250 microns)

- Easily applied in a high throughput manufacturing process

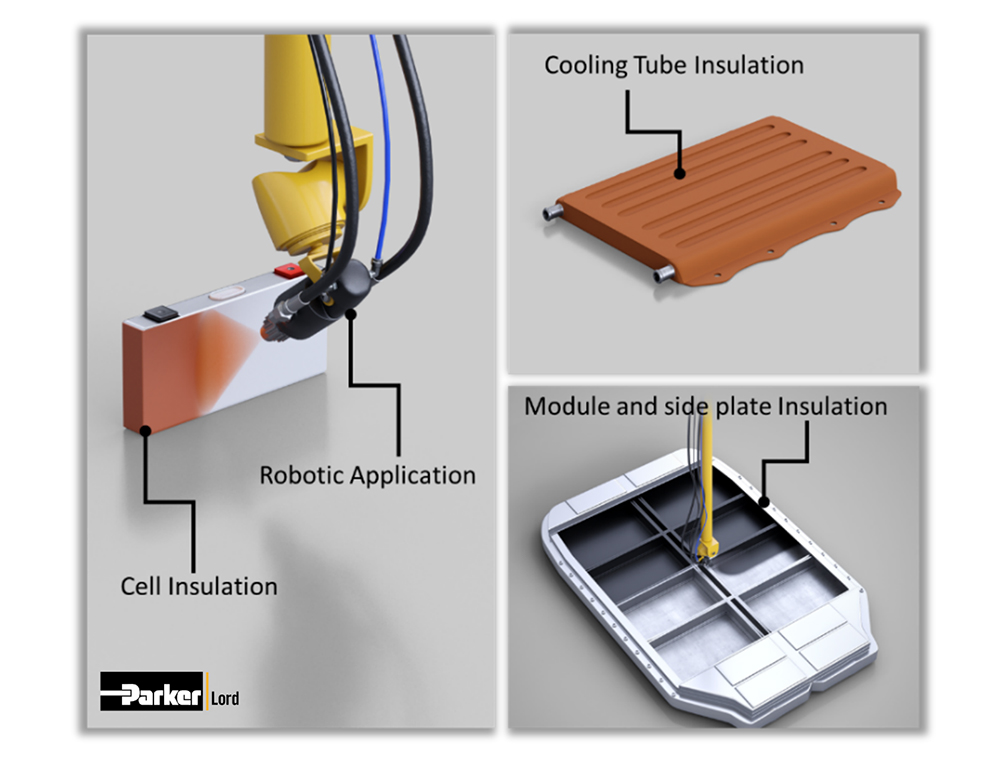

With applications in battery cells, bus bars, cooling plates, side plates, walls, and battery lids, dielectric materials are critical in EV components where electrical isolation is required (Figure 1).

Completed Testing

For the study, a series of five tests were completed:

- Hipot Test: High Potential (Hipot) equipment was used to measure the breakdown voltage of dielectric materials per ASTM D3755. The breakdown voltage is the minimum voltage where a material experiences electrical breakdown and becomes electrically conductive.

- Adhesion: This test looks at how well the coating stick to the aluminum. Crosshatch adhesion was conducted per ASTM D3359. A rating of 5 indicates excellent adhesion and a rating of zero indicates poor adhesion.

- Environmental Aging: Coated specimens for hipot and adhesion data were aged at 85°C / 85% RH for up to 3 weeks in an ESPEC environmental chamber. Another set of specimens were exposed to thermal cold shock cycling from -40°C to 100°C for up to 120 cycles using a Thermotron SE400 environmental chamber.

- Failure Mode: The failure mode was analyzed to determine the weakest point for the bonding assembly. A cohesive coating failure indicates that the weakest point is the cohesive strength of the coating.

- Thermal Conductivity: Thermal conductivity was measured according to ASTM D5470 using 1400 TIM tester. Aluminum disks (33 mm diameter, 3 mm thick) were coated with varying film thicknesses (50 to 200 micron) of dielectric material. The disks were compressed to 50 kPa pressure in the TIM tester.

Technical Comparisons

1) Cost and Productivity

Besides performance, the economics of a dielectric material solution is critical to the decision of which to implement for a manufacturer. While each dielectric material has its target application, it is important to assess each product’s application time, ease of automation, labor and energy costs, and the potential equipment investment required for a full-rate automotive application.

When considering cost and productivity, PET films are easy to apply to geometrically simple parts but challenging for complex parts. On the other hand, powder coating has the advantage that excess material can be collected and reused but can be difficult to achieve even coating thickness on complicated geometries. LORD JMC coatings use standard applications and large curing ovens while also not relying on static deposition. Meaning, it is sprayed where it is wanted and not sprayed where it is not wanted. Meanwhile, Sipiol UV has low upfront capital investment and can be robotically spray-applied, making it an efficient option.

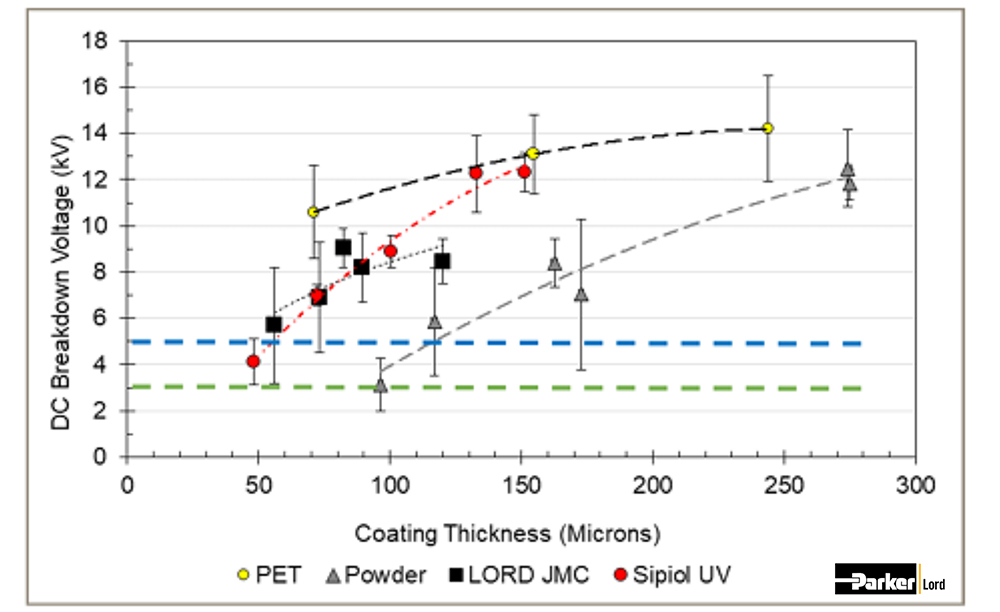

2) Electrical Isolation

Electrical isolation is a primary requirement for the safety and performance of EV battery components. Minimum breakdown voltage is used to quantify a material’s electrical isolation performance and is measured via direct current hipot equipment in the air. Higher material breakdown voltage translates into improved electrical isolation and improved safety and performance of EV battery components.

Parker Lord found that:

- PET film has the highest dielectric strength but lower adhesion strength and is limited to flat surfaces.

- Powder coating has the lowest dielectric strength and requires a thicker film to meet voltage withstand requirements.

- Both Sipiol UV and LORD JMC coatings can achieve high voltage withstand with a thickness of 90-120 microns and are recommended for battery components with sharper edges and radii.

3) Edge Coverage

Often battery components will have edges and corners that require coverage for electrical isolation. As illustrated in Figure 2, electrical isolation performance depends on film thickness. Thus, determining the coating film thickness on an edge is important for understanding the electrical isolation performance.

Of the four coatings applied to two different substrates and analyzed for coverage and thickness, Sipiol UV and powder coating were effective in uniformly coating sharp corners, but LORD JMC had difficulty with sharp corners and imperfections in the metal. Therefore, a higher thickness target may be needed for very sharp radii to achieve adequate electrical protection.

4) Thermal Conductivity

In addition to electrical isolation, thermal management is another critical requirement for EV performance. Poor thermal management may result in thermal runaway events, reduce the efficiency of electronic components, and lower the EV’s power. Hence, it is important to remove heat from battery and powertrain components efficiently.

For EV applications requiring high electrical isolation and heat transfer, LORD JMC is the preferred product, followed by powder coating, Sipiol UV, and PET. It is important to consider both a material’s inherent thermal conductivity and the required film thickness for electrical isolation when assessing its overall heat transfer capabilities.

5) Adhesion and Environment

Adhesion is another important factor when evaluating which dielectric materials. Once the dielectric material is applied, it must remain on the component surface to provide dielectric protection for the product’s life. In addition, good adhesion to the metal substrate and adhesive is important for effective heat transfer. The required adhesion strength varies depending on where it is used.

Of all the materials tested, Sipiol UV had the highest adhesion strength, followed by powder coating and LORD JMC. PET film had the lowest adhesion strength, which could be improved with plasma treatment. The thermal shock cycling had minimal negative effects on adhesion for all materials, while exposure to 85°C / 85% RH condition had moderate reductions in adhesion strength. All four dielectric materials have excellent crosshatch adhesion to aluminum before and after environmental exposure.

Summary and Conclusions

The choice of dielectric materials for specific battery components depends on many factors, including cost and productivity, dielectric strength, edge coverage, thermal conductivity, adhesion, and electrical isolation.

Continuous development of the mentioned dielectric materials is ongoing. There are products that are being developed to improve heat transfer, adhesion, corner coverage, ease of application, and cost. It’s important to identify the key performance and production attributes and work closely with coating suppliers and manufacturing integrators to implement successful solutions. If you are interested in learning more about Lord JMC or Sipiol UV, reach out to Parker Lord today. And to download their whitepaper, visit this link.