Liebherr, in partnership with KOSTAL, has released an automated connection system for battery pack module connectors. Compared with screwed and rigid busbars, plug connections with flexible cables offer easier assembly and disassembly, because the flexible lines can compensate for positioning tolerances of several millimeters in the battery modules. The contact parts are touch-protected to remove the danger of exposed high-voltage contacts. Liebherr also says the plug connections can withstand vibrations that might detach screwed busbars.

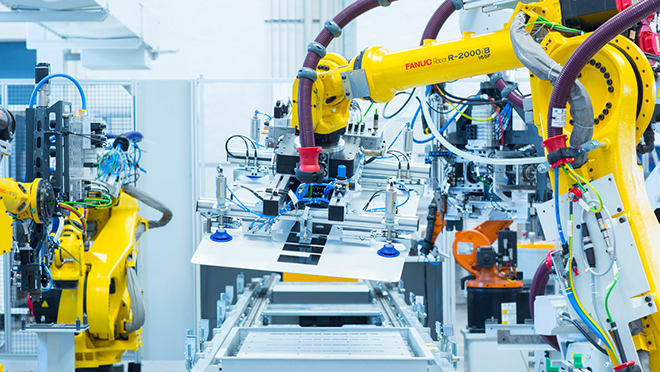

The engineering challenge for automating the pluggable connectors on soft components has been low resistance to shape changes. Connectors can become deformed from small stresses, such as their own weight. Liebherr’s system has two cooperating robots each grip one end of the cable and perform the plugging process with temporally and geometrically coordinated movements. A 2D camera detects the position of the slots and allows the robots to compensate for positioning tolerances. The mechanical plugging process is performed using a pneumatic cylinder, and a spring assembly limits the force transfer to the module. Liebherr can also address the laying of the cables in the desired position and geometry using suitable cable bend grips.

Source: Liebherr