Specialized in electronics services for 30 years, SERMA Group carries out expertise and tests on batteries, power electronics and electric motors.

In order to support the strong growth of the electrical energy sector, SERMA opened in 2019 an additional test, expertise and services platform of more than 5000m² in France, near Bordeaux.

SERMA Energy supports its customers throughout the value chain and offers them a complete range of development and homologation tests. This service is combined with engineering and industrialization support.

The platform is organized into 3 departments:

- Batteries (cells, modules and packs),

- Power electronics (converters, on-board or fixed chargers, inverters),

- E-powertrain (e-motors, powertrains, etc.).

The resources are designed to meet all current and future standard technologies with power levels that can exceed a megawatt.

BATTERY

Battery technology is constantly changing as are the associated robustness, reliability and safety requirements.

SERMA meets these requirements by operating on the different electric battery components: the cells, the modules and the packs, but also on the battery management system (BMS).

- Performance, endurance, environmental, abuse and mechanical tests

- Testing and support to certification: UN38.3, ECE R100, SAE, IEC, GB and other standards

- Battery construction and comparative analyses in the laboratory, teardown and root cause analysis

- Physical-chemical and gas analyses.

- Validation plan definition

- Consulting on the choice of technology with our experts, our R&D teams and our testing labs

- Design support

- Multiphysics Simulation

- Reliability plan, Health Monitoring (HM) and Prognostics Health Management (PHM)

- BMS design

- Battery assembly line and industrialisation audit

- Test bench engineering

- Training

Test means: more than 200 testing channels located in 4 testing platforms.

POWER ELECTRONICS

The purpose of SERMA’s power electronics expertise and technical resources is to optimize the performance and output of electronic components and systems using testing that covers high powers.

For power electronics, SERMA offers testing, consulting and expertise services for inverters, converters, chargers and components.

- Electrical, performance, endurance, environmental and mechanical tests

- Validation plan definition

- Consulting technology choices with our experts, our R&D teams and our labs

- Simulation

- Component material analyses and expertise

- Reliability plan, Health Monitoring (HM) and Prognostics Health Management (PHM)

- Active (MOSFET, IGBT, HEMT, Si, SiC, GaN, etc.) and passive components (capacitors, induction coils, transformers, windings) construction and failure analyses.

- System and electronic component assembly line and industrialisation audit

- Test bench engineering

- Training

Test means: more than 10 testing channels located in 2 platforms.

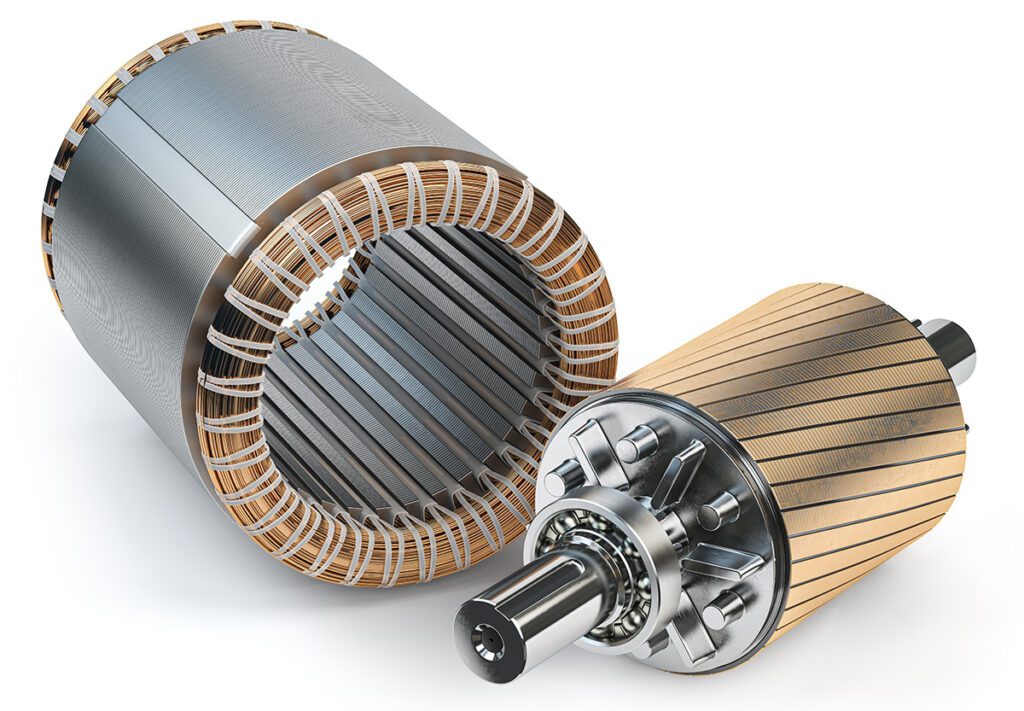

E-POWERTRAIN

Vehicle performances mainly depend on battery and power electronics performance, but also on e-motors performances. As for any product, the design and development phases play a major part in guaranteeing product performance, reliability and life duration.

SERMA Energy offers high performance testing for e-powertrain thanks to last generation equipment’s and experts. Here is an overview of our services:

- Performance, endurance, mechanical, endurance, environmental testing

- Testing for R85 certification

- Validation plan definition

- Simulation

- Reliability plan

- Failure analyses by our experts, R&D teams and laboratories

- Test bench engineering

- Training

Test means: e-drive, e-axle, front to front, back to back and e-powertrain test rigs up to 5 000 N.m / 800kW / 40 000 rpm.

A 4.0 TEST CENTER

The new SERMA Energy’s test centre is permanently connected: the building, the test equipment’s and systems. SERMA has developed its own “Test Field Overview” to follow all the test benches on giant screens installed at strategic points.

During the test bench installation, SERMA offers video monitoring and/or photo reporting of the entire installation to its customers, who also have real-time remote access to their data, reports and test monitoring.

All critical equipment are closely monitored and send their health status in real time. The temperature and humidity of the building are monitored to guarantee the stability of the measurements made on site (20° – 50% RH).

To equip its platform, SERMA Energy has selected the best suppliers of test equipment’s.

See the video of SERMA Energy:

SERMA Energy works closely with all SERMA Group subsidiaries on qualification, engineering, industrialization and physical expertise and with partner laboratories on mechanical and chemical tests.

The company addresses all sectors impacted by electrification: the automotive market, faced with the transition from internal combustion engines to all-electric, the aeronautical industry for hybrid and electric aircraft, and the tertiary sector for smart grids (intelligent energy storage and management networks).

SERMA Energy continues its development and sets up in Spain. The SERMA group has established a privileged and historical partnership with RENAULT. To meet the new challenges of its customers, SERMA Energy is developing a test centre in Spain.

SERMA Energy completes the group’s technological facilities serving the microelectronics, embedded systems and cybersecurity fields, and consolidates the one-stop shop for expertise and consultancy that it offers around electronics and systems.

Regarding its development around batteries and hydrogen, SERMA Group is considering several possibilities for its future locations in France.