We all have rules and regulations we need to follow. For manufacturers selling vehicles in the US, there are government-mandated rules and regulations in place for vehicle labeling. These labels contain important vehicle details – make and model, VIN, fuel economy, safety rating, MSRP – that are used by consumers when making a purchase decision.

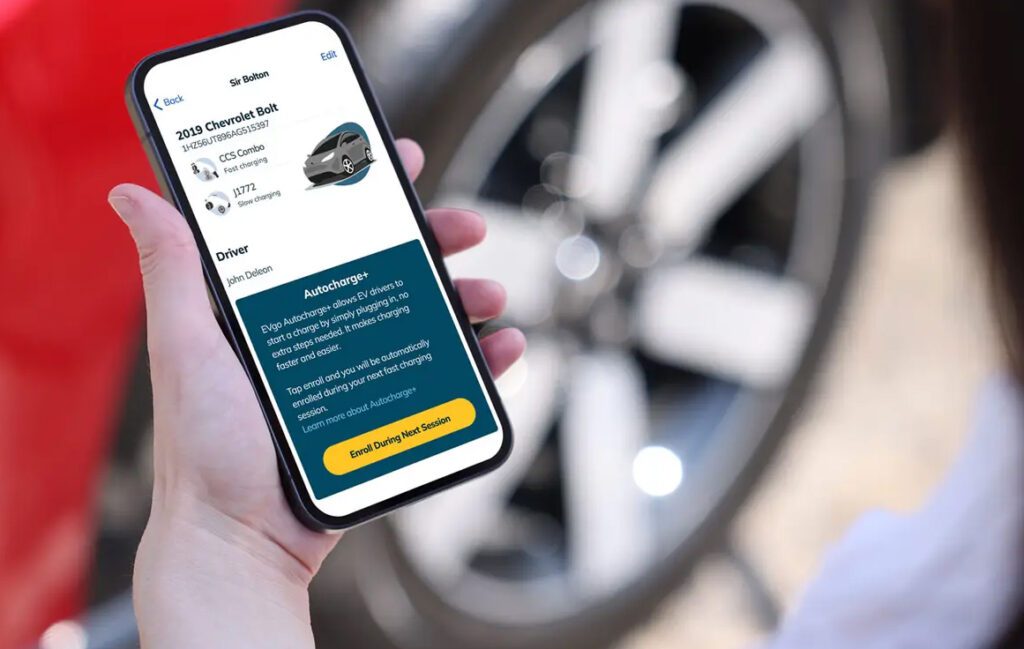

For electric vehicles, these labels include MPGe (a miles-per-gallon equivalent created by the EPA) for city, highway and combined city/highway; kilowatt-hours of electricity required to operate the vehicle for 100 miles; an estimate of cost savings over a five-year period compared to owning a gas-powered vehicle rated at 27mpg; the average number of miles the vehicle can operate on a charge; and more.

In addition to mandated labels, some automakers elect to include optional labels highlighting features and benefits such as new technology, exclusive VIP services, optional packages and accessories.

But you can’t just print any label and put it wherever you want on a vehicle before it rolls off the production line. Your labeling process and approach needs to be given top consideration early in the sourcing process because it’s a complex activity requiring a knowledgeable staff to coordinate and manage approvals.

- Not having a proven process and/or knowledgeable people leading your labeling efforts can create negative financial implications. These can include rushed deadlines, future recalls and delays in vehicle launch timing.

- Government-mandated labels are considered formal parts of the vehicle, so you cannot ship a vehicle without them.

- Information from various departments needs to be collected and verified, so lead times of at least 4 months may be needed to design and implement a label meeting an OEM’s manufacturing specifics.

The must-haves in vehicle labeling

There are numerous details involved in each aspect of a label, which in addition to avoiding costly delays in a vehicle launch or recalls, is another reason to start the process early and engage labeling experts. Some of the required elements to vehicle labels:

- Labels need to be permanent. They must be riveted or affixed in a way so they can’t be removed without destroying or defacing it.

- Placement is key. Depending on the type of vehicle, required placement varies; it must be in a place that makes it easily readable without moving any part of the vehicle, except an outer door.

- Content is not variable. The National Highway Traffic and Safety Association outlines specific information that must be included on vehicle labels. This includes details identifying the manufacturer, date of manufacture, weight, classification and more. And, depending on the type and weight of a vehicle, specific statements must be included.

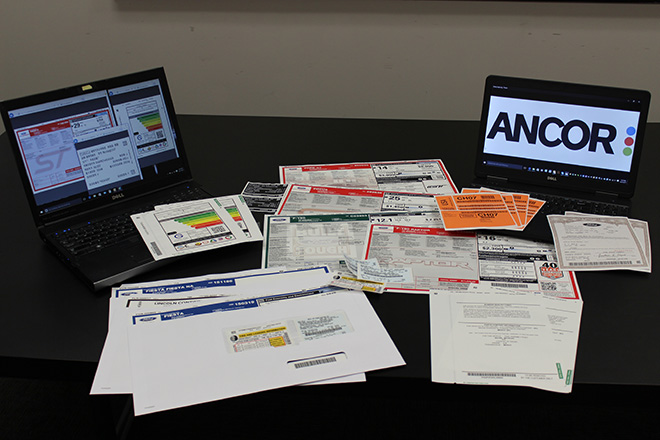

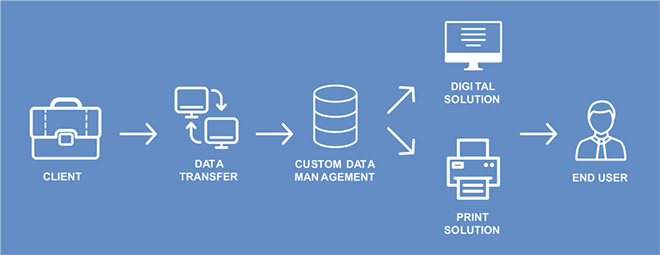

Ancor employs a sophisticated, technology-enabled production process, utilizing internally developed, custom database-driven software to meet customers’ advanced data processing and file transfer needs.

Finding the right labeling partner

Today’s vehicle can have up to 30,000 individual parts, ranging from dashboards to screws. But automakers do not make all these parts, they partner with suppliers who are experts in individual products and systems. This results in a large number of companies producing parts for a vehicle, so automakers have robust systems in place to manage their networks of trusted suppliers.

The same approach – a comprehensive process and trusted partner – should be applied to vehicle labeling to ensure it is done correctly, helping to avoid significant cost issues, including recalls and warranty risks. That’s where Ancor Information Management can help.

- Ancor’s proprietary, one-of-a-kind data tool, AutoDoc, processes, produces and securely creates labels. Labeling information is uploaded into, Ancor Webview™ where PDFs of all government-required labels are available, allowing you to review label data prior to mass production. These PDFs are retained for a period of time determined by each customer.

- Ancor incorporates business rules and data integrity checks to catch erroneous data combinations so if incorrect information is provided, it is quickly identified and flagged. It’s another layer of security integrated in our processes to ensure labels are accurate before being sent to the plant and affixed to vehicles.

- Throughout the label production process, Ancor conducts multi-level quality inspections. From data incorporation to printing and packing for distribution, labels are quality checked at every stage. And it works – Ancor produces more than 3 million flawless automotive label packages each year, making us a trusted and valued partner for vehicle labeling needs.

- Ancor has a proven launch process to meet product deadlines. For more than 30 years they have managed VIN-specific data to create new car labels for every Ford and Lincoln vehicle produced in or imported to the North American market.

Ancor – a trusted labeling partner

Ancor just scratched the surface about vehicle labeling. The good news is, the experts at Ancor are not only well-versed in the automotive industry and its rules and regulations, but they also have solutions that effectively and efficiently gather and validate label information, and then produce the actual label.

For more than three decades, Ancor has helped clients save time, money and valuable resources by delivering VIN-specific automotive labels with speed, quality and efficiency. They produce over 3 million flawless automotive label packages every single year and are constantly evaluating and investing in our training, software, equipment and systems. Contact Ancor to learn more about our vehicle labeling services and how we can be your single source for all your vehicle label needs.