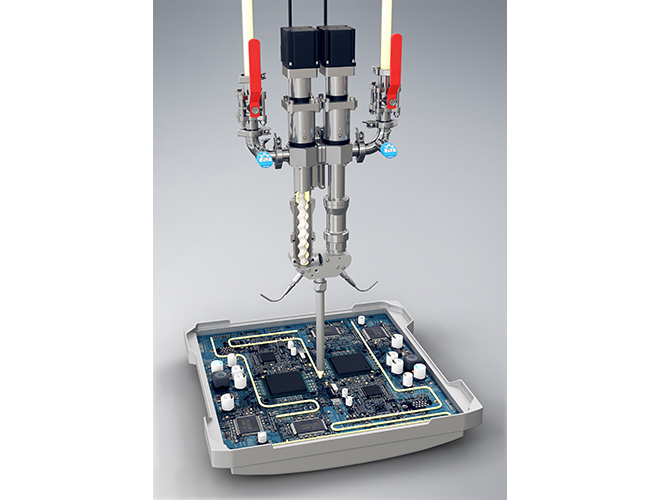

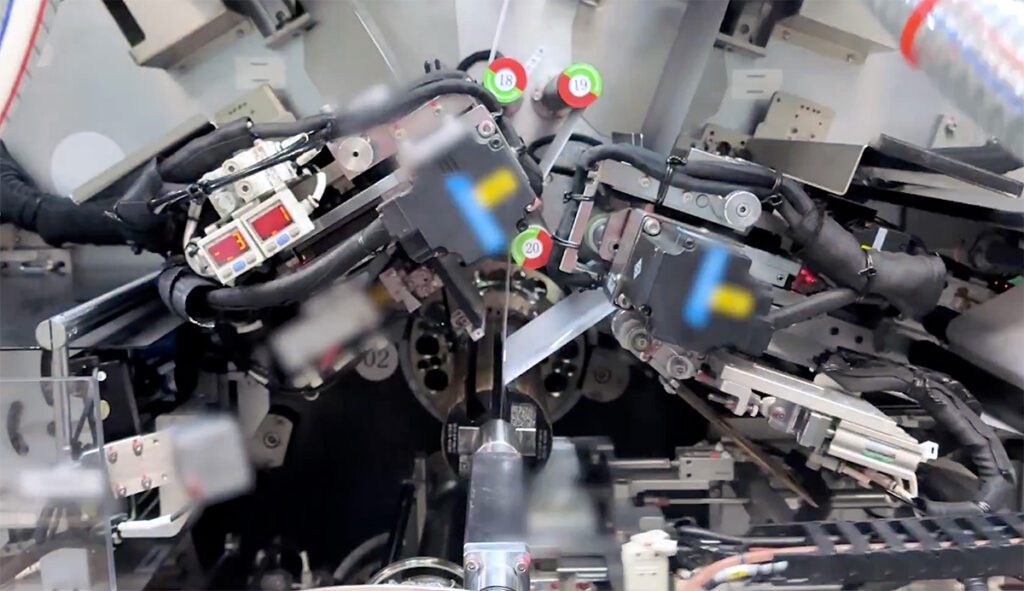

Whether bonding, encapsulating or sealing – there are a lot of dosing applications in e-mobility manufacturing. Users and dosing systems are often faced with the challenge of reliably and precisely dosing of highly viscous or abrasive materials. Learn how to perfectly dispense various materials: Low to highly viscous 1- and 2-component materials, such as gap fillers, heat-conducting pastes, or liquid seals, can be dosed with high precision and without changing the material properties. ViscoTec dosing systems are also used for potting, sealing and bonding applications or trickle impregnation. Dosing systems based on the endless piston principle offer excellent conditions for the processing of all low to high viscosity 1-component and 2-component materials, such as gap filler and liquid seals or in potting and bonding applications. The combination of rotor and stator with defined volumetric chambers in the dispensers ensures a volumetrically precise, low-shear and virtually pulsation-free application. The endless piston dosing technology is viscosity-independent, valve-less, and backflow-free. This guarantees a highly reproducible dosing result.

ViscoTec dosing systems are particularly impressive when dosing abrasive materials with outstanding results. Sedimentation of the filler of different densities is prevented by the consistent volume flow in the endless piston dispenser.