It is fully expected that electric vehicle (EV) sales will erode internal combustion engine (ICE) market share over the next 10 – 15 years and new global government regulations will ensure this holds true. A recent Deloitte EV market analysis predicts EVs will have captured 30 – 35% of the global passenger car market by 2030. In fact, EV-volumes.com’s global battery-electric vehicles (BEV) and plug-in hybrid EVs (PHEV) data shows global EV sales of 2.65M units through June 2021, a 168% increase over the same six-month period in 2020!

Today, gas stations are plentiful since the infrastructure has been in place for years and you can pull into a gas station and fill up in five minutes or less. However, one of the major barriers to large-scale adoption of all-electric cars is that the EV charging infrastructure is far behind. This gives many current and potential EV owners range anxiety over finding a charge station while on the road. Level 1 chargers working on 110 V will charge a typical EV to full capacity overnight. A Level 2 charger running on 220 V will charge a battery in about eight hours. DC super chargers with 1,000 V or morecan charge a battery in minutes, but this high voltage presents a significant challenge to safely and effectively insulating cables and components while charging.

EVOLVING REQUIREMENTS

Electrical failure in a plastic-insulating component occurs either through the wall section or across the part surface. Because the electrical properties of EV components are influenced by polymer chemistry as well as ambient conditions including moisture, humidity, chemicals, additives, and contaminants, special materials are required for safe and consistent functioning over the product’s life span. Moreover, operating voltages, currently in the 440 – 800 V range, will increase and necessitate further material enhancements. EV applications must be designed to withstand extreme temperature and weather conditions so the insulating materials should exhibit hydrolysis and thermal degradation resistance as well as excellent electrical insulation properties.

Important polymer electrical properties that measure electrical insulating effectiveness are dielectric strength and volume resistivity (both through the polymer), and comparative tracking index (CTI) (across the surface). High voltage moving across a part surface may cause failure via tracking, erosion, melting, or flaming if test conditions exceed the polymer’s capability. The Inclined Plane Test (IPT) is often used to predict material performance under those conditions and may be applied at voltages up to 2.5 kV. The CTI test is limited to 600 V, or slightly above, before the voltage creates a corona effect that pulls the salt solution off the plaque surface and renders the CTI test ineffective.

Flammability is another critical property to consider for high-voltage EV applications. The need for V0, V2 or HB flame-rated materials is dependent on component design but in most cases a V0 flame-rated material is desired. In some applications, the polymer component is designed to insulate a service technician from the high voltage components inside. The high voltage is shielded from the outer shell by another component that allows the shell to be made from an HB or V2 flame rated material to reduce cost.

MATERIAL SOLUTIONS FOR EV APPLICATIONS

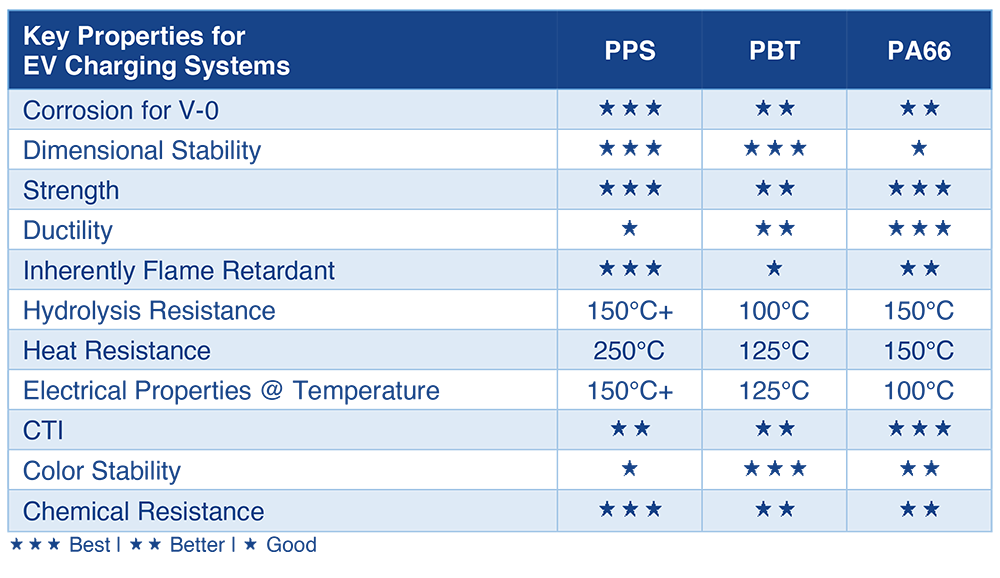

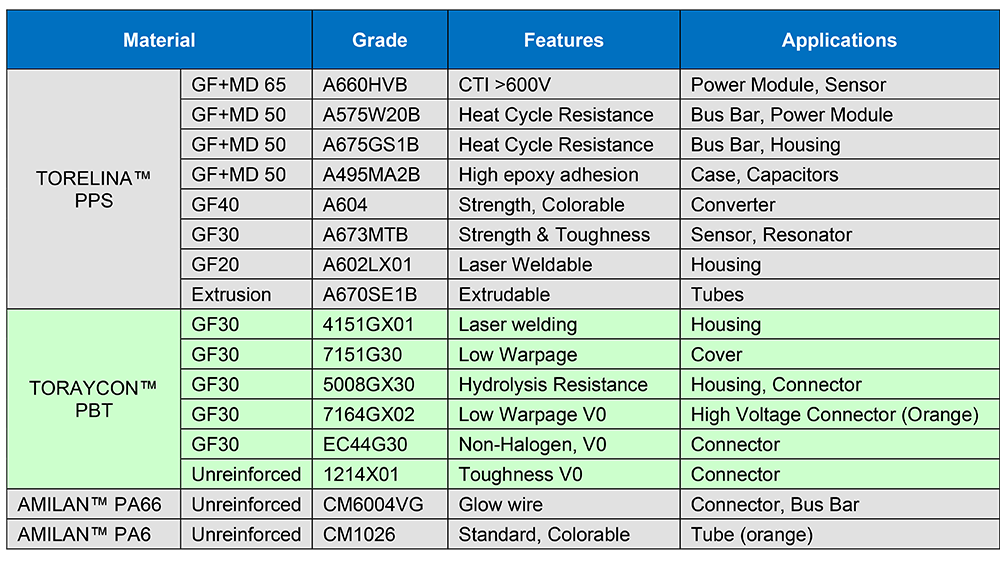

To support EV charging systems and the many components used in electric vehicles, Toray has designed a series of polyphenylene sulfide (PPS), polybutylene terephthalate (PBT), and polyamide (PA66) products with unique properties and characteristics, making them desirable for high voltage applications.

Polyphenylene sulfide (PPS) is a high-performance, engineering thermoplastic characterized by an unusual combination of properties including a superior blend of short- and long-term thermal stability, exceptionally high modulus and creep resistance, and an outstanding resistance to a wide variety of aggressive chemical environments. It is inherently V0 flame rated and eliminates the need to use FR additives that typically result in high plate-out, blooming, and corrosion of electrical contact surfaces.

PPS is the material of choice to produce complex parts with very tight tolerances. This polymer exhibits excellent dimensional stability even when used under high temperature and high humidity conditions. PPS has excellent electrical insulation properties that are better retained when used in hot and wet environments compared to PA66, PBT and PPA (Figure 1).

Figure 1. Insulation Properties of PPS, PPA, PBT and PA66

TORELINATM A660HVB PPS is the resin of choice in demanding high voltage power module housing applications (Image 1) due to its excellent electric and mechanical property retention in extreme conditions and long-term requirements. Click here to view the technical data sheet and UL Yellow card for TORELINATM A660HVB PPS.

Image 1. Power Module Housing

Polybutylene terephthalate (PBT) is a semi-crystalline engineering thermoplastic featuring outstanding electrical characteristics and long-term heat, chemical, and weather resistance. PBT is widely used in precision parts, automotive connectors, bobbins, and coil cases, and electronic and electrical components.

PBT resins have good color stability at room and elevated temperatures. This allows for excellent orange color stability for high voltage EV applications. PBT is recommended for use up to 125°C in high heat applications and where electrical insulation properties must be maintained. Special care should be used to position hydrolysis resistant PBT grades in hot, wet applications. Click here to view TORAY’s technical data sheet and UL Yellow card for TORAYCONTM PBT.

Polyamide (PA66) is a major, high-performance class of engineering thermoplastics because of its good balance of properties. PA66 exhibits very good ductility in unfilled and glass-filled grades, partially due to its non-aromatic structure and the fact that it absorbs moisture that plasticizes it but leads to less dimensional stability. PA66 also exhibits excellent hydrolysis resistance, heat stability, and electrical insulation properties; however, its electrical insulation properties do begin to fall off with increasing moisture and temperature. PA66 does not exhibit very good color stability over time at room or elevated temperature but it is recommended for use up to 150°C for high heat applications and up to 100°C where electrical insulation properties need to be maintained. At temperatures above 100°C, dielectric strength falls below 10 kV/mm and volume resistivity falls below 1E+10 Ohm-cm, typically accepted as critical values below where electrical insulation may become compromised. Click here to view TORAY’s technical data sheet and UL Yellow card for AMILANTM PA66.

Key attributes of these polymer families are shown in Table 1 and the electrical properties of Toray’s material solutions are shown in Table 2.

Table 1. Key Performance Attributes of PPS, PBT, and PA66

Table 2. Toray’s Portfolio of Materials for Electrical and e-Mobility Applications

Toray’s family of high-performance engineering materials exhibit a range of outstanding mechanical, electrical and flammability properties, making them ideally suited for EV charging system applications.

Fill in the form below to discuss your application with a material expert and to learn more or visit www.toray.com.