German automotive and industrial systems manufacturer ZF has opened its third plant in Shenyang, China, known as ZF Electric Mobility Systems, to produce and sell products such as electric axle drives for EVs.

The transfer of production lines and equipment to the Shenyang plant is proceeding. The next stage will focus on refining the electric drive system assembly and inspection production line to reach volume production in 2025.

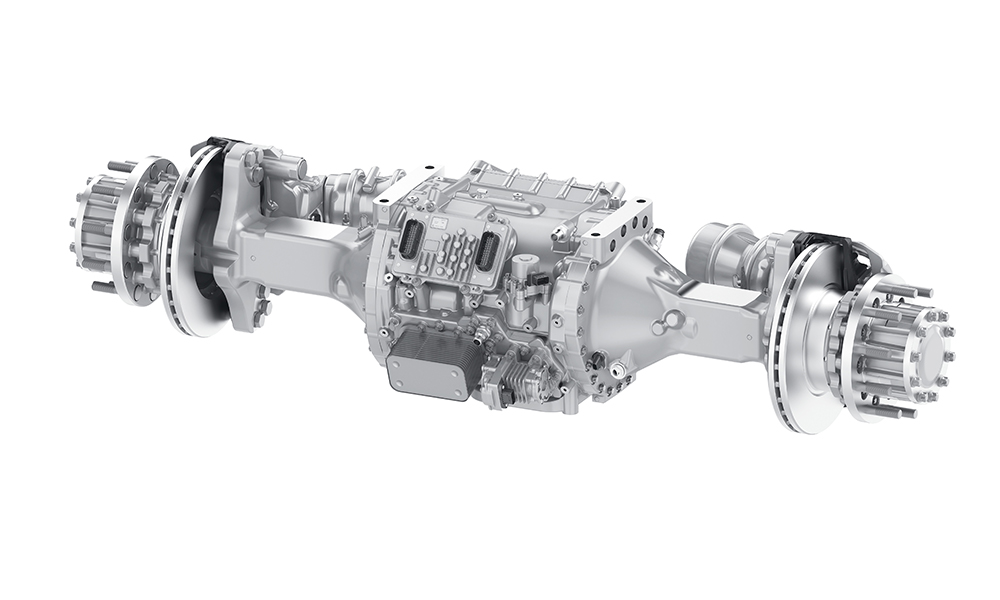

The core components of the electric axle drives are based on ZF’s modular kit electric drive platform and cover front and rear axles, including motors, power electronics and reducers.

The modular design can meet power requirements from 100 kW to 300 kW and offers the flexibility to switch between synchronous and asynchronous motors depending on customer requirements. The motor features a hairpin winding for higher power and torque density, higher efficiency and optimized power output. The power electronics incorporate ZF’s High 2.0 silicon carbide (SiC) technology and can be upgraded to the 800 V platform, improving function safety while optimizing cost. The reducer design has also been improved to ensure optimum efficiency.

ZF Electrified Powertrain Technologies started operations in Hangzhou in 2022 to manufacture 800 V electric drives and reducers. ZF Guangzhou Technical Center opened in 2023. Construction of a second facility, ZF Guangzhou Electronics Plant, started at the site and is also scheduled to be completed in 2025.

“ZF attaches great importance to the Chinese market and the opening of the new plant in Shenyang fully demonstrates ZF’s determination to continue to invest and innovate in China,” said Renee Wang, Executive Vice President, President of China and Operation Asia Pacific at ZF. “To adapt to the ‘China speed’ and Chinese efficiency, we are advancing our localization strategy, including raw materials, equipment, R&D and others to accelerate the localization process.”

Source: ZF