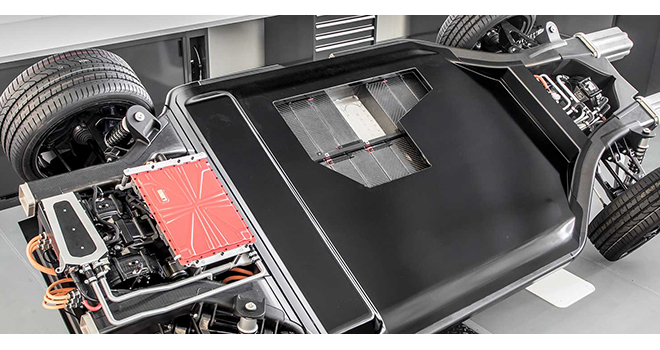

Williams Advanced Engineering (WAE), a UK-based tech and engineering firm, says it is working on new carbon composites that offer comparable performance to existing options, but at a cost that brings them within reach of mainstream applications.

WAE says carbon fiber reinforced polymer’s (CFRP) high strength-to-weight ratio, stiffness, and resistance to fatigue and its environment make it a good choice for a variety of industries and applications, especially the automotive industry, in which lightweighting is seen as a primary tool to meet increasingly stringent fuel economy targets, and to support the range required from EVs.

Despite these benefits, WAE says, a number of factors have held back the mass adoption of CFRP – most notably cost.

These challenges have seen the application of CRFP largely confined to niche applications. In the automotive sector, for example, a body-in-white structure produced with traditional composite techniques is typically around 60% lighter than steel, yet around 20 times more expensive. The company says this has limited its application to low-volume/high-cost vehicles, or situations in which the vehicle manufacturer subsidizes the process as part of its learning around new technologies.

WAE hopes two of its new technologies, known as 223 and Racetrak, can usher in a major change in the affordability of composite materials.

WAE Technical Director Paul McNamara said, “We are focusing our expertise on energy management, aerodynamics, thermodynamics and lightweighting. As tools for efficiency improvement, these are all highly synergistic, so considering them as an integrated system allows us to increase significantly the total benefits.”

Source: Williams Advanced Engineering