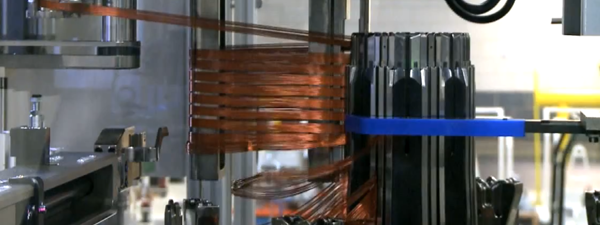

The American-made LEAF is getting closer to reality every day. Nissan has released a new video of the amazing machinery that builds its eMotor, a high tech marvel with more than a mile of copper wiring inside. It takes more time to assemble an electric motor than a gas engine; Nissan says it takes about 25 people per shift.

Nissan’s eMotors are currently assembled in Japan, but soon they will also be produced in Decherd, Tennessee, about 70 miles from the main LEAF plant in Smyrna. Adam Reed, Nissan’s globally certified trainer for eMotor production, has been spending time at Nissan’s global headquarters in Japan learning how to sculpt the motors.

“The winding takes place on a very complex piece of equipment,” said Reed. “It has two parts at a time traversing inside the equipment going in different directions. So it’s very hard to keep up with sometimes. It’s very exciting to get it started and knowing that when that first LEAF comes off the line in Smyrna, we’re going to have our name somewhere on the motor.”

Source: Nissan