Sponsored by ODU-USA

Although mass-produced hybrid and electric cars have been commercially available since the 1990’s, the field is still very much in an evolutionary state, driven largely by two key factors:

- Greater vehicle range

- Shorter stops at re-charging stations

The second of these does not necessarily imply actual re-charging. A more recent innovation involved swapping of a vehicle’s (discharged) batteries with a fully charged set. However, the added cost of this method has led to its rejection by many vehicle manufacturers. Tesla’s Elon Musk, originally a proponent of battery swapping, has now reversed his position and the company is presently focused on producing increasingly fast charging systems.

The Charging Interface

The rate at which batteries can be recharged depends on the applied voltage and current, both of which are constrained by the physical characteristics of the recipient battery. Needless to say, as vehicle and battery technologies have evolved, so too has the technology of the connectors required to deliver higher voltages and currents. To further complicate matters, different regions of the world have adopted different connector standards to fulfill these changing needs. The current variety of connection types that comply with international standards is summarized in Table 1, including examples of the corresponding connector ports used in charging stations. Not shown in Table 1 is Tesla’s Supercharger port, because the company chose to develop its own port capable of delivering up to 120 kW at a time when none of the standard ports could deliver more than 62.5 kW.

In order to enable North American charger systems (SAE J1772 compliant) to be used with Tesla vehicles, Tesla turned to ODU-USA, a leading supplier of electrical contacts, contact systems and connector solutions. ODU completely re-designed the Tesla J1772 Adapter, incorporating ODU’s TURNTAC contact technology (Fig. 1).

ODU products are also the preferred choice of many well-known and established Tier 1 charging station and port manufacturers. Among the reasons these companies selected ODU are the superior performance characteristics of ODU’s electrical contacts, as well as their overall product quality and outstanding customer support. The ODU TURNTAC® family (1) of sockets, for example, are rated to have a life expectancy exceeding 10,000 mating cycles, and an insertion misalignment tolerance up to 5°. In addition they offer a low and stable connection and disconnection force requirement.

The continuing trend towards charging at higher voltages and currents has introduced a new challenge – heat. No matter how conductive the cable and connectors are, there will always be some electrical resistance at normal operating temperatures, and hence some loss of energy in the form of heat.

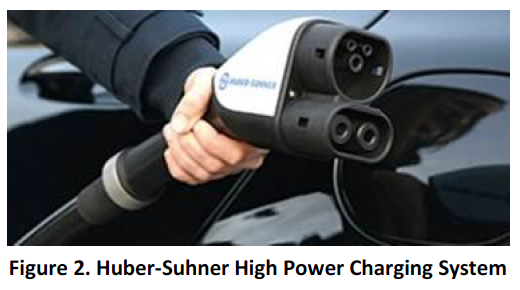

To address this issue, one customer of ODU has developed an innovative solution. Huber-Suhner’s RADOX ® high power charging port incorporates an integrated liquid cooling system that enables delivery of up to 400 kW, in anticipation of battery technologies currently under development. These super-fast systems will allow charging to 80% of full battery capacity in as little as 15 minutes. The RADOX system cools both the cable and connector, hence enabling use of a much smaller cable cross-section than uncooled fast-charging systems. This in turn enables greater cable flexibility, lighter weight and easier handling. Connectors are available for both the North American (U.S. and Canada) and European CCS ports. To ensure the greatest reliability and ease-of-use, Huber-Suhner selected ODU TURNTAC contacts for its ports.

For home charger systems, time is not a critical factor. Most electric vehicle owners simply plug-in their vehicle at the end of the day and wake-up the next morning with a fully charged set of batteries. For this reason, home charger systems typically use lower power, non-CCS ports. Since there are about as many home charger systems as there are EV owners, this segment of the EV market is obviously much higher volume than the high power systems used at commercial charging stations.

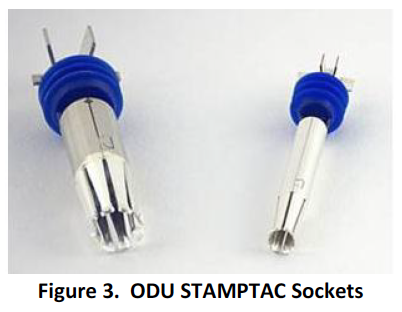

A more critical factor for EV owners is the cost of their home charger system. With this in mind, ODU also offers a more economical contact solution for high volume connector manufacturers. The STAMPTAC® family (2) is ideal for SAE J1772 and IEC 62196 connectors, and is normally capable of weatherproof performance to the IP67 standard (3). With the addition of silicon over mold sealing, these contacts can even achieve IP69 compliance. STAMPTAC contacts have similar characteristics to TURNTAC, including a lifetime exceeding 10,000 mating cycles, and can be scaled for various cable cross sections and customer requirements.

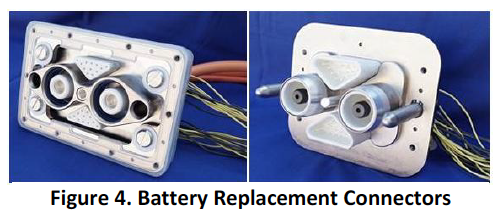

Battery Swapping

Although battery swapping for family cars has been out of favor in the U.S. and Europe in recent years, it has nonetheless been used for heavier duty electric vehicles such as light trucks and limousines. ODU has also served this market, offering custom connectors such as that shown in Figure 4. These connectors offer axial and radial tolerance compensation of +/- 5mm, high vibration absorption and EMC damping for ampacities greater than 300 Amps.

In China, which has recently been leading the way in charging systems capable of delivering greater than 120 kW, there has been a trend back to battery swapping for all types of vehicles. This trend may be short-lived however, due to the widespread deployment of fast and superfast charging stations throughout the country. As of the end of 2016, there were more than 150,000 such stations and this is expected to rise to 800,000 by 2020.

On-Board Connections

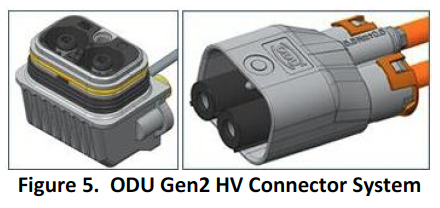

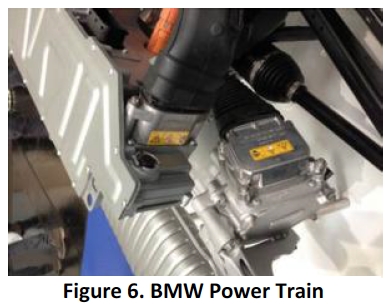

The EV charging interface is not the only place in which connectors are required. Within the vehicle itself, multiple batteries must be inter-connected and the entire bank requires connection to the EV’s electric drive system. For these functions, ODU offers custom 2 and 3-pole connectors similar to those shown in Figures 5 and 6 respectively.

The Gen2 connectors are capable of transmitting currents up to 160 Amps at 85°C ambient temperature and offer 65 dB electro-magnetic shielding, as well as IP69 compliance. Bearing in mind that these connectors are likely to experience considerable vibration when their host vehicle is driven over rough pavements, they are also designed to withstand such vibration.

ODU’s 3-pole connectors are available for cables with scalable cross-sections according to the customer’s requirements. They offer similar ease of insertion to their 2-pole counterparts and are capable of delivering 200 Amps at ambient temperatures up to 125°C, with a 50 mm2 cable. For non-operating environments, they can withstand temperatures up to 185°C. Their vibration tolerance complies with severity class 4 – the highest class defined by the German auto makers LV 214 connector test specification. These excellent characteristics are the reasons that ODU HV connectors have been selected by companies such as Mercedes, BMW and Daimler.

What’s Next?

Electric Vehicle technology is among the most dynamic fields of engineering in today’s world. The ongoing quest for greater vehicle range and shorter battery re-charging times present exciting challenges to companies in the field. Looking ahead, we can expect to see deployment of docking stations that will fully automate the process of plugging-in ultrafast chargers to client vehicles, so that clients never have to exit theirs cars if they don’t wish to. With ultrafast chargers capable of delivering up to 600 kW, the time required for a full charge may drop to as low as 10 minutes. This may become a reality within the next 5 years.

As self-driving cars proliferate over the coming years, one might even anticipate that your vehicle will decide for itself when to go for a re-charge! Much of the necessary technology already exists, so perhaps this fanciful scenario is truly possible within the next 15 years.

ODU has always been a leader in its field. No matter how the future of electric vehicles unfolds, ODU will be there to meet new challenges with new and advanced connector solutions.

For more specific product information regarding ODU products, please contact our customer account specialists:

sales@odu-usa.com

(805) 484-0540

References

(1) ODU TURNTAC® brochure

(2) ODU STAMPTAC®

(3) IP Code (Wikipedia)