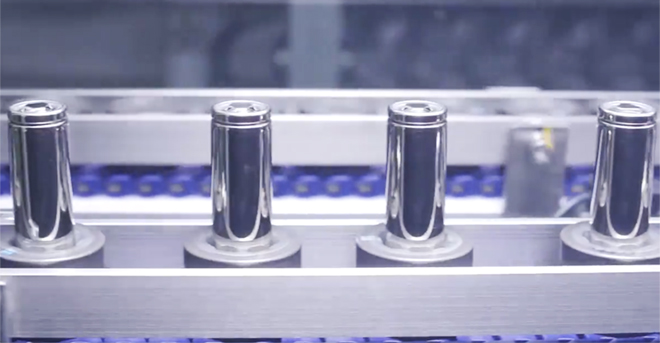

It seems we’ve been waiting forever, but in fact, as these things go, it happened with lightning speed. Tesla’s game-changing Gigafactory has started producing battery cells, destined for the Powerwall and other energy storage products and, beginning in the second quarter, the Model 3. The sprawling Nevada plant is already assembling utility-scale Powerpacks for Southern California Edison.

This is a historic event for several reasons. It’s a big win for American manufacturing, giving us a foothold in an industry currently dominated by China, Japan, and South Korea, which together supplied 88% of the global market for lithium-ion cells in 2015. Over 2,900 people are already working at the 4.9-million-square-foot facility (less than a third of its eventual size), and Tesla and Panasonic expect to have 6,500 full-time employees there by 2018. The Gigafactory is a large and prominent illustration that the future of manufacturing lies in high-tech clean energy, not in 20th-century smokestack industries.

For Tesla, the Gig is of existential importance. Without it, the company could never come anywhere near its goal of 500,000 Model 3 sales by 2018, because there simply isn’t enough lithium-ion battery production in the world. Furthermore, for Model 3 (and EVs in general) to be profitable, battery prices will need to come down significantly. Tesla is counting on the massive scale of the $5-billion Gigafactory to drive down costs enough to make EVs competitive with legacy vehicles.