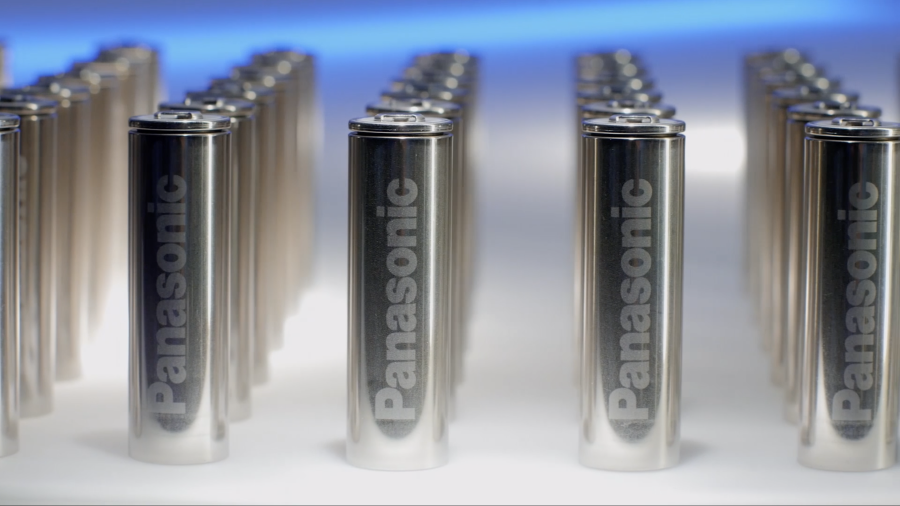

Japanese battery manufacturer Panasonic Energy has launched a recycling initiative for nickel used in lithium-ion battery cathode materials, in collaboration with Japanese non-ferrous metal refining and cathode material manufacturer Sumitomo Metal Mining.

Through this new collaboration, battery scrap from Panasonic Energy’s Suminoe Factory in Osaka will be processed and partly recovered as nickel sulfate at Sumitomo Metal Mining’s Toyo Smelter & Refinery, and its Niihama Nickel Refinery in Ehime prefecture. The resulting nickel sulfate will be utilized in the manufacturing of cathode materials, which will subsequently be recycled in Panasonic Energy’s lithium-ion batteries.

Following an ongoing partnership cemented with Redwood Materials in the US in 2022, the collaboration accelerates recycling efforts in Japan. Since 2017, Sumitomo Metal Mining has been operating a business recovering and recycling copper and nickel from end-of-life lithium-ion batteries and battery scrap, repurposing them as raw materials for cathode production.

The companies plan to extend the program beyond 2026 to include other key cathode materials, such as lithium and cobalt. Panasonic Energy has set the target of achieving 20% recycled cathode material content in its automotive batteries by 2027.

“Building a sustainable recycling scheme for end-of-life lithium-ion batteries is crucial for the future expansion of EVs. We are advancing initiatives in both Japan and the US, and through the partnership with Sumitomo Metal Mining, with its deep expertise in non-ferrous metal recycling, we are accelerating our efforts toward realizing a circular economy,” said Kazuo Tadanobu, CEO of Panasonic Energy.

Source: Panasonic Energy