Mercedes-Benz Trucks will put its new electric truck, the eActros, on the road with customers for real-world trials in 2018. Ten vehicles in two variants, with a gross vehicle weight of 18 or 25 tons, will be tested under real-life conditions by ten customers in Germany and Switzerland.

These customers operate in different sectors and categories, from groceries to building supplies to raw materials. The range of requirements means that the vehicles are fitted with a variety of bodies, including refrigerated boxes, tankers and tarpaulin sides.

“This will enable us to satisfy the many requests we have had from customers and to gain even more insight,” said Stefan Buchner, Head of Mercedes-Benz Trucks. “Our aim is to achieve series production and market maturity for a range of economically competitive electric trucks for use in heavy-duty transport operations with effect from 2021.”

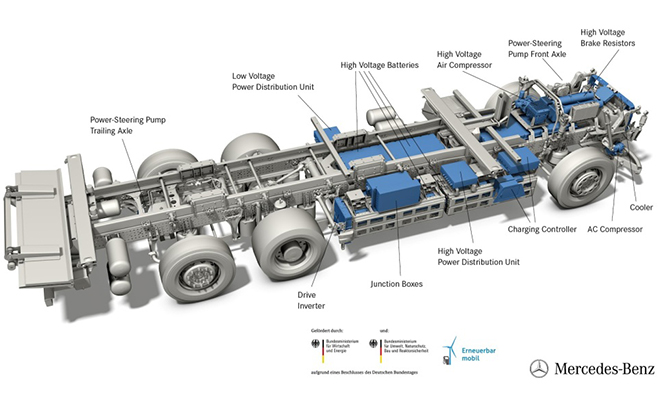

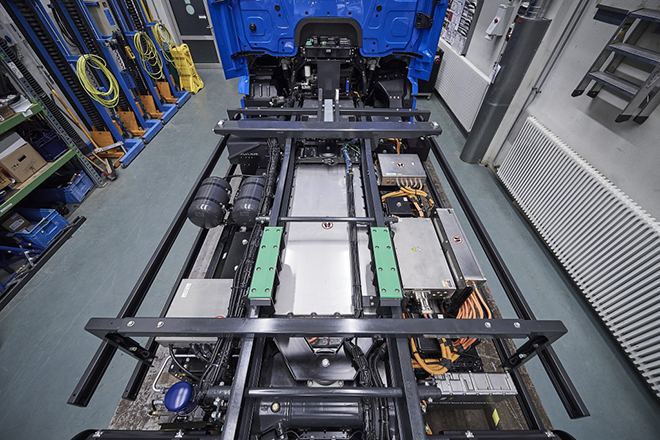

The eActros is based on the frame of the legacy Actros truck, but the vehicle architecture has been configured specifically for an electric drive system. The drive axle is based on the ZF AVE 130 that has already been used as a low-floor portal axle in Mercedes hybrid and fuel cell buses. The axle housing has been redesigned and mounted in a higher position, increasing ground clearance to more than 20 cm.

The drive system comprises two electric motors located close to the rear-axle wheel hubs. These three-phase asynchronous motors are liquid-cooled and operate with a nominal voltage of 400 volts. They generate an output of 125 kW each, with maximum torque of 485 Nm each. The gearing ratios convert this into 11 000 Nm each, resulting in driving performance on a par with that of a diesel truck.

There are 11 battery packs, with total output of 240 kWh, yielding a range of up to 200 km. These have already proven their worth in service with Daimler subsidiary EvoBus. “Synergies within the Group like these allow us to pool our experiences, shorten development times and, of course, also save costs,” says Buchner.

The battery packs are protected by steel housings with mountings that are designed to give way and deform in the event of a collision. The high-voltage batteries also supply energy to ancillary components such as the air compressor for the braking system, the power steering pump, the compressor for the cab AC system and the refrigerated body. High-speed charging uses the CCS standard.

“We have developed a vehicle that has been configured from the outset for electric mobility,” says Stefan Buchner. “Compared with our prototype, quite a few technical changes have been made: the power supply is now ensured by eleven battery packs in all, and wherever possible we have used already proven components that are ready, or very close to ready, for use in series production.”

At the launch event for the eActros test fleet, Daimler Head of Trucks Martin Daum took a fling at Tesla, telling Bloomberg that he has doubts that the Californians can achieve the specs they’ve announced for the Tesla Semi. “If Tesla really delivers on this promise, we’ll obviously buy two trucks – one to take apart and one to test because if that happens, something has passed us by. But for now, the same laws of physics apply in Germany and in California.”

Those impressive specs, as Electrek and others have noted, don’t seem possible with Tesla’s current battery cells – most analysts believe that Tesla is counting on significant improvements in battery tech. Can Tesla improve performance by its announced production date of 2019? Daimler apparently thinks not, otherwise the eActros will already be behind the times when it goes into production in 2021.