INFICON, a supplier of leak-detection equipment, predicts that the percentage of global automotive plants with robotic leak-detection systems will jump from 5 percent today to 20 percent or more by 2024. The company attributes the rise to growing interest in EVs and autonomous vehicles.

Robotic leak-detection techniques are either static and dynamic. In static detection, a robotic arm remains stationary and analyzes a specific point on a car part. In dynamic detection, the robotic arm scans continuously along the part’s surface.

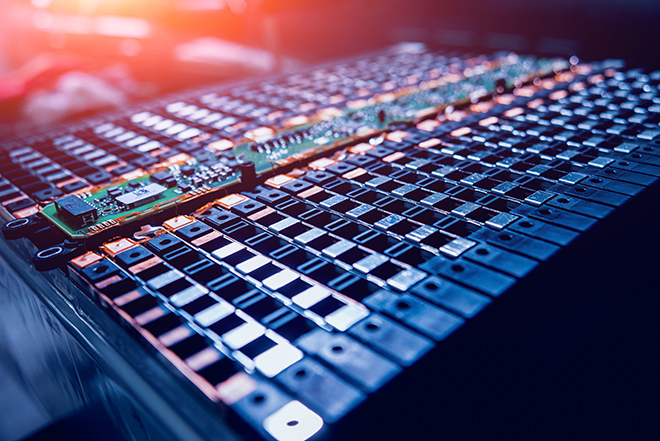

At a recent forum, INFICON Sales Manager Thomas Parker said, “EV traction batteries, fuel-cell membrane electrode assemblies, autonomous vehicle LIDAR systems, and other mission-critical automotive components are on the industry’s ‘can’t-leak list’ globally. These electric- and autonomous-vehicle components are safety-critical, and must provide trouble-free service throughout the life of a vehicle. Whenever people put their lives in the hands of a self-driving machine, for example, they expect it to work flawlessly.”

Source: INFICON