German chemical company Henkel has launched its Bergquist Liqui Form TLF 6500 CGel-SF to deliver heat dissipation for autonomous driving systems.

By delivering a higher level of conductivity, the thermal curable gel is designed to prevent performance degradation and protect the sensitive ADAS domain controllers that enable real-time vehicle decision-making from heat degradation and damage. As ADAS systems process higher volumes of sensor and vehicle data at higher speeds, effective heat management will become critical to ensure the performance, reliability, and longevity of these components, the company said.

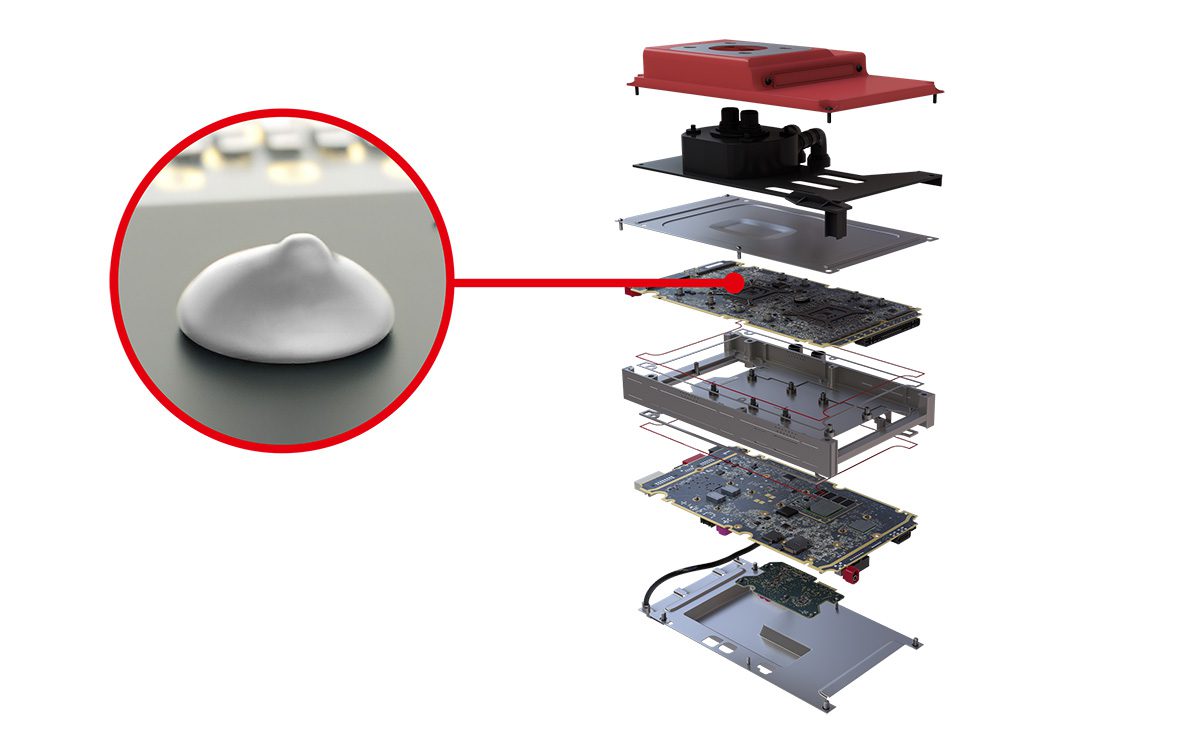

The silicone-free thermal management material has a conductivity of 6.5 W/(m·K) and is designed to provide reliability and easier handling. As a cured elastomer, it offers ultra-low compression stress to protect fragile assemblies and sensitive electronic components. It fills air voids and irregular gaps to ensure even heat transfer across the surface and can be dispensed at high speed to match with just-in-time manufacture processing.

The gel avoids cracking or thermal failure during thermal cycling, extending component lifespan. It protects operators at the production line and avoids fogging issues for components with lenses such as cameras.

“As safety standards and OEM and driver expectations evolve, ADAS systems are becoming ever more sophisticated. This makes it vital to effectively manage the heat generated by domain controllers to ensure their long-term reliability. Our top OEM partners, for example, are launching a high-intelligence vehicle platform which needs to process up to 4.5 terabytes of data per hour. This fivefold increase of data generates high heat concentration, requiring more effective thermal solutions to avoid component failure,” said Nancy Yang, Henkel’s Business Development Manager for Automotive Electronics North America.

Source: Henkel