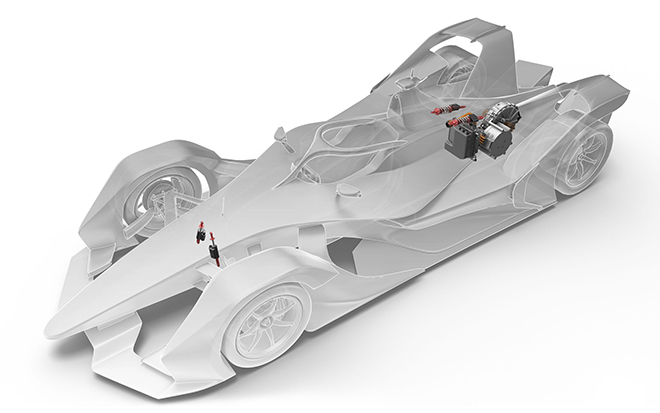

Since 2016, German parts maker ZF has supplied technology for French EV maker Venturi’s team in the FIA Formula E racing series.

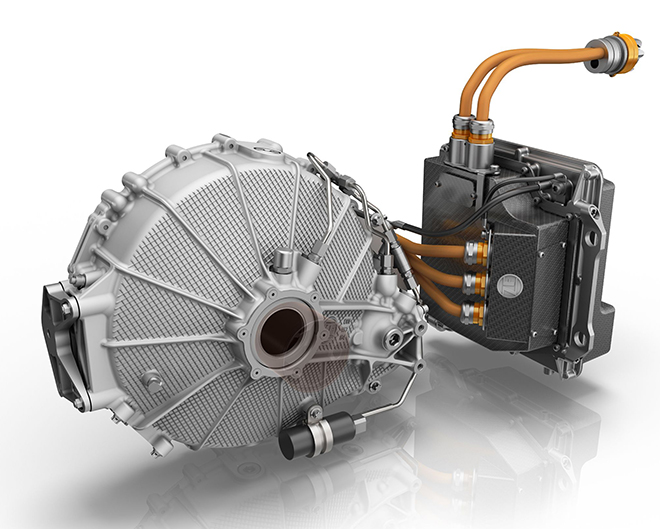

ZF has developed an electric drive for the team, which includes a 250 kW electric motor with a specially designed transmission ratio and power electronics. ZF says this drive enjoys much higher energy conversion efficiency than volume production applications, and it plans to incorporate these new developments in its electric drives for street vehicles.

For the racing vehicles, ZF used a lightweight metal alloy for the transmission housing and carbon in the power electronics. Dry sump lubrication increases the energy conversion efficiency in the transmission’s reduction gears. The ZF team used silicon carbide in the power electronics, which it says can be designed ten times thinner than current silicon types, leading to lower internal resistance. The results, ZF says, are increased battery efficiency and range.

The parts maker hopes that concepts it initially developed for racing cars will gradually find their way into volume production applications, including a special winding design for electric motor stators. ZF specifically hopes to introduce silicon carbide into volume production for power electronics in three to four years.

Jörg Grotendorst, Head of ZF E-Mobility, said, “A lot of the experience we’ve gained from the racing application will impact on future ZF products.”

Source: ZF