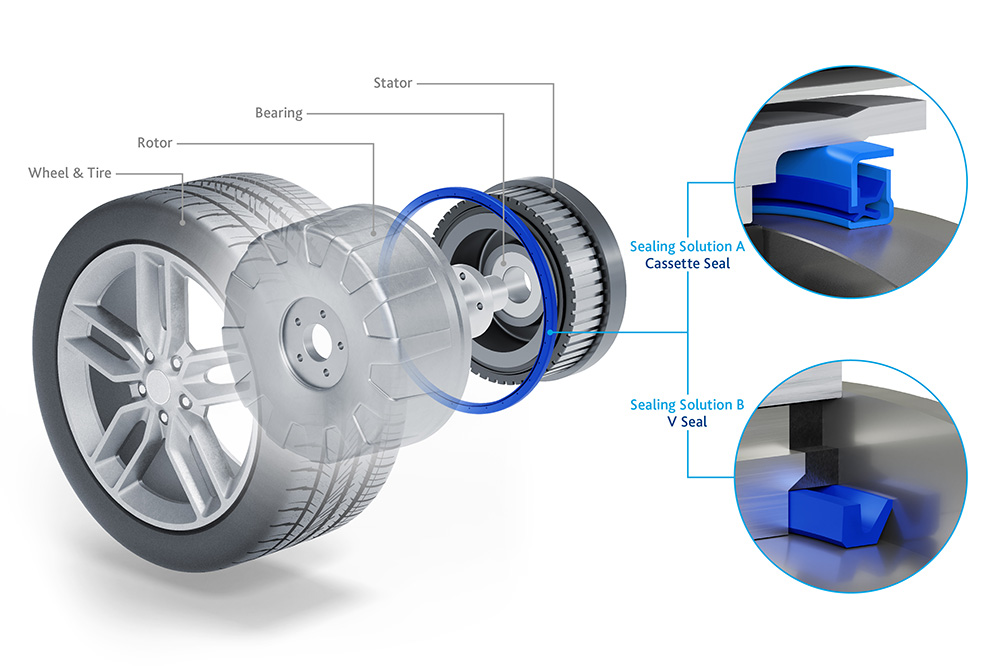

Germany-based Freudenberg Sealing Technologies offers a sealing geometry to support electric motor manufacturers at the development stage.

In-wheel motors for EVs enable wheel-specific torque control, enhanced comfort and more design space within the vehicle. They create a lower center of gravity, tighter turning radius and higher load capacity for electric buses and offer added value as a combined trailer drive for e-trucks or as a generator for refrigerated trailers.

Freudenberg’s seal provides protection against dirt and water and adjusts dynamically according to the rotational speed of the wheel to prevent major friction losses.

The company has developed two seal designs. A cassette seal has a double sealing lip and mating contact surface installed in a closed system, using materials made from stainless steel and rubber compounds. The seal geometry can be scaled to an installation space diameter of up to 530 mm and is adjustable to the respective speed range. The cassette seal offers long service life and high functional reliability, as it can achieve up to 500,000 km and protection class IP67.

The second design, a V-seal, works in an open system. It has wear-resistant elastomers with good sliding properties and attractive manufacturing costs, making it a plug-and-play solution for flexible applications.

“Freudenberg has positioned the sealing lip in such a way that high contact pressure maximizes sealing performance at low rotational speeds. At higher speeds, both the contact pressure and the friction are significantly reduced by the generated centrifugal forces. Depending on the customer’s requirements, the seal can even be fully lifted off the stator, which also eliminates friction, thus significantly increasing the lifetime of the seal,” said Luca Breusa, a Product Developer at Freudenberg.

Source: Freudenberg Sealing Technologies