US automakers know they have to raise their EV games to catch up with China. The times call for action, not more empty slogans, so it’s encouraging to hear Ford announce a new electrification initiative that actually appears to have some substance to it.

“We have all lived through far too many ‘good college tries’ by Detroit automakers to make affordable vehicles that end up with idled plants, layoffs and uncertainty. So, this had to be a strong, sustainable and profitable business,” said Ford President and CEO Jim Farley. “We knew there was no incremental path to success.”

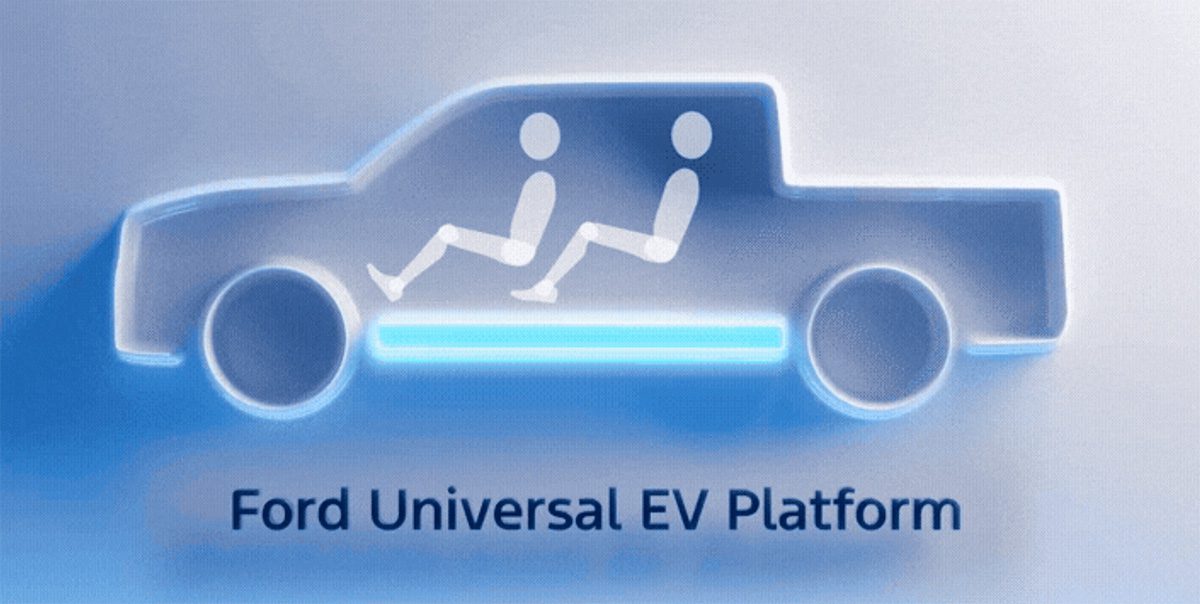

Here at Charged, we’ve also seen some automakers (including Ford), announce “college tries” and then not try very hard. However, Farley’s description of Ford’s new Universal EV Platform includes some innovations that are right in line with the current state of the EV art (some of them inspired by, or at least parallelling, innovations introduced by Tesla, Rivian, or Chinese brands).

“We empowered a tiny skunkworks team three time zones away from Detroit,” said Farley. “We tore up the moving assembly line concept and designed a better one. And we found a path to be the first automaker to make prismatic LFP batteries in the US.”

The first EV built on the new platform will be a midsize, four-door electric pickup that will be assembled at Ford’s Louisville Assembly Plant for US and export markets. Its launch is scheduled for 2027.

“The platform reduces parts by 20% versus a typical vehicle, with 25% fewer fasteners, 40% fewer workstations dock-to-dock in the plant and 15% faster assembly time,” says Ford. The wiring harness in the new midsize truck will be more than 4,000 feet shorter and 10 kilograms lighter than the one used in Ford’s first-gen electric SUV.

“Lithium iron phosphate (LFP) prismatic batteries enable space and weight savings, while delivering cost reduction,” Ford continues. “The platform’s cobalt-free and nickel-free LFP battery pack is a structural sub-assembly that also serves as the vehicle’s floor. This low center of gravity improves handling, creates a quiet cabin, and provides a surprising amount of interior space.”

“We assembled a really brilliant collection of minds across Ford and unleashed them to find new solutions to old problems,” said Doug Field, Ford’s Chief EV, Digital and Design Officer. “We applied first‑principles engineering, pushing to the limits of physics to make it fun to drive and compete on affordability. Our new zonal electric architecture unlocks capabilities the industry has never seen.”

Major innovations are also in store for the production line. Ford says its new Universal EV Production System will transform the traditional assembly line into an “assembly tree.” Instead of one long conveyor, three sub-assemblies will run down their own lines simultaneously and then join together.

“Large single-piece aluminum unicastings [what a certain other automaker calls megacastings] replace dozens of smaller parts, enabling the front and rear of the vehicle to be assembled separately,” sez the Blue Oval. “The front and rear are then combined with the third sub-assembly, the structural battery, which is independently assembled with seats, consoles and carpeting, to form the vehicle.

“Because of the integration between the Ford Universal EV Production System and Platform, assembly of the midsize electric truck could be up to 40% faster than Louisville Assembly Plant’s current vehicles. Some of that time will be reinvested into insourcing and automation to improve quality and cost, ultimately netting a 15% speed improvement.”

Ford plans to invest nearly $2 billion at the Louisville Assembly Plant, which will be expanded by 52,000 square feet in order to move material more efficiently.

The project is supported by an incentive offer from the Kentucky Economic Development Finance Authority.

“Today, Ford and Team Kentucky are introducing the world to the future of automotive production,” said Kentucky Governor Andy Beshear, adding that the project is expected to create 2,200 new jobs. “Ford and Kentucky have been a tremendous team for more than 100 years, and that partnership has never been stronger than it is today.”

Ford has already invested some $3 billion in BlueOval Battery Park Michigan, which will build the prismatic LFP batteries for the midsize electric truck starting next year.

Source: Ford